Thorium-base fuel assembly and small pressurized water reactor

A fuel assembly and fuel technology, applied in the field of nuclear reactors, can solve the problems that the core refueling cycle cannot reach 5-10 years, etc., and achieve the improvement of neutron economy and safety, strong reactivity control ability, and transformation ability improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

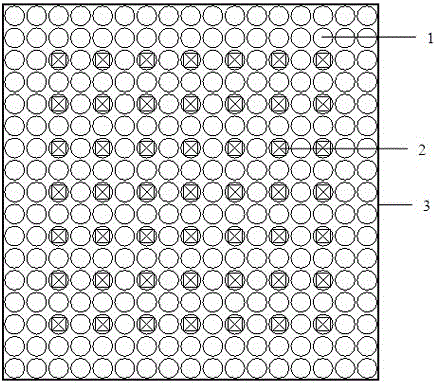

[0031] Such as figure 1 As shown, a thorium-based fuel assembly includes 232 fuel rods 1 with a cladding thickness of 0.5 mm and an outer diameter of 9.1 mm, 57 guide tubes 2 with an outer diameter of 9.1 mm, fuel rods 1, and guide tubes 2 Arranged at intervals, the distance between adjacent fuel rods 1 is 1.0mm, the distance between adjacent fuel rods 1 and guide tube 2 is 1.0mm, and the distance between fuel assemblies is 172.7mm. 235 UO with 20% U abundance 2 fuel, UO 2 Fuel and ThO 2 The fuel ratio is 1:1, 235 U percentage content is 8.8%, 232 The Th content is 43.9%. The fuel rods 1 and guide tubes 2 are evenly arranged in a square grid to form a square fuel assembly 4 with a square assembly box 3 on the periphery.

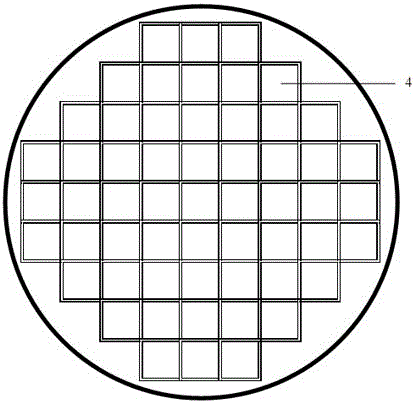

[0032] Such as figure 2 As shown, a small pressurized water reactor adopts figure 1 The shown square fuel assembly 4 is structured as figure 2 In the shown core, a total of 57 boxes of fuel assemblies are arranged. The center distance of the fuel as...

Embodiment 2

[0035] This embodiment is based on embodiment 1, such as figure 1 As shown, a thorium-based fuel assembly includes 232 fuel rods 1 with a cladding thickness of 0.5 mm and an outer diameter of 9.0 mm, 57 guide tubes 2 with an outer diameter of 9.0 mm, fuel rods 1, and guide tubes 2 Arranged at intervals, the distance between adjacent fuel rods 1 is 1.0mm, the distance between adjacent fuel rods 1 and guide tube 2 is 1.0mm, and the distance between fuel assemblies is 172.7mm. 239 PuO with a Pu abundance of 18% 2 Fuel, PuO 2 Fuel and ThO 2 The fuel ratio is 1:1, 239 The total percentage of Pu is 8.8%, 232 The Th content is 43.9%. The fuel rods 1 and guide tubes 2 are evenly arranged in a square grid to form a square fuel assembly 4 with a square assembly box 3 on the periphery.

[0036] Such as figure 2 As shown, a small pressurized water reactor adopts figure 1 The shown square fuel assembly 4 is structured as figure 2 In the shown core, a total of 57 boxes of fuel as...

Embodiment 3

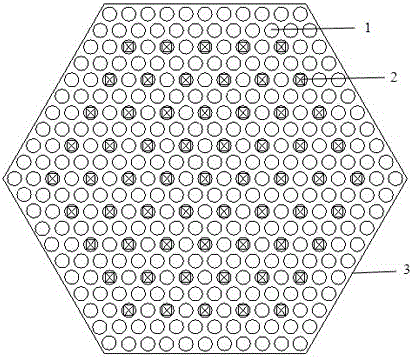

[0039] Such as image 3As shown, a thorium-based fuel assembly includes 270 fuel rods 1 with a cladding thickness of 0.5 mm and an outer diameter of 9.1 mm, 61 guide tubes 2 with an outer diameter of 9.1 mm, fuel rods 1, and guide tubes 2 Arranged at intervals, the distance between adjacent fuel rods 1 is 1.0mm, the distance between adjacent fuel rods 1 and guide tube 2 is 1.0mm, the distance between fuel assemblies is 186mm, and the abundance of 235U mixed in fuel pellets is 20% UO 2 fuel, UO 2 Fuel and ThO 2 The fuel ratio is 1:1, 235 U percentage content is 8.8%, 232 The Th content is 43.9%. The fuel rods 1 and guide tubes 2 are evenly arranged in a triangular grid to form a regular hexagonal fuel assembly 5 with a regular hexagonal assembly box on the periphery.

[0040] Such as Figure 4 As shown, a small pressurized water reactor adopts image 3 The shown regular hexagonal fuel assembly 5 is structured as Figure 4 In the shown core, a total of 55 boxes of fuel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com