Arc extinguish chamber and circuit breaker employing same

A technology of arc extinguishing chamber and circuit breaker, which is applied in the field of circuit breaker and arc extinguishing chamber, can solve the problems of limited opening and closing speed, and achieve the effect of increasing opening and closing speed, reducing weight and good closing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

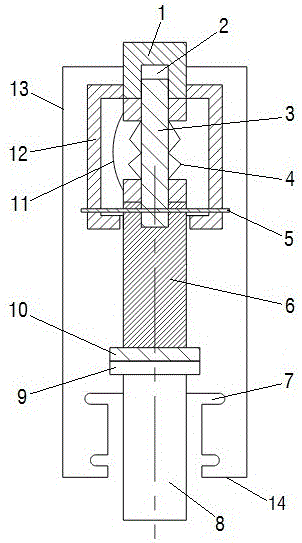

[0020] An example of a circuit breaker is Figure 1~Figure 2 As shown, it includes an arc extinguishing chamber and a repulsion mechanism (not shown in the figure), and the arc extinguishing chamber includes a housing 13, and the housing 13 is provided with a first contact 10 and a second contact 9 along the upper and lower sides, and the second contact 9 The lower end is connected with the conductive rod 8 at the movable end, and the repulsion mechanism is directly connected with the conductive rod 8 at the movable end. A bellows 7 is arranged on the periphery of the moving end conductive rod 8, one end of the bellows 7 is connected to the moving end conductive rod 8, and the other end is connected to the cover plate 14 at the lower end of the arc extinguishing chamber.

[0021] The upper end of the first contact 10 is provided with a conductive rod 6 , the upper end of the conductive rod 6 is provided with a guide rod 3 , and a spring 4 is sheathed outside the guide rod 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com