A battery module with automatic temperature equalization

A battery module and automatic technology, which is applied to battery components, batteries, secondary batteries, etc., can solve the problems of reduced safety, battery pack sealing level not up to IP67, and ineffective effects, etc., to achieve cost reduction Effect

Active Publication Date: 2019-03-15

镇江润安管理咨询有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] 1. Natural cooling is to dissipate heat from the battery pack through the wind generated during the running of the car, the effect is not obvious, especially in hot areas, it has little effect

[0004] 2. The air-cooling system uses the wind from the air conditioner to dissipate heat inside the battery pack. However, there must be vents, so that the sealing level of the battery pack cannot reach IP67, and the safety will be reduced.

[0005] 3. The effect of the liquid cooling system is the best. The cost of the entire cooling system is relatively expensive. The existing liquid cooling system requires liquid to enter and exit, and the sealing level will also decrease, and the safety is low.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

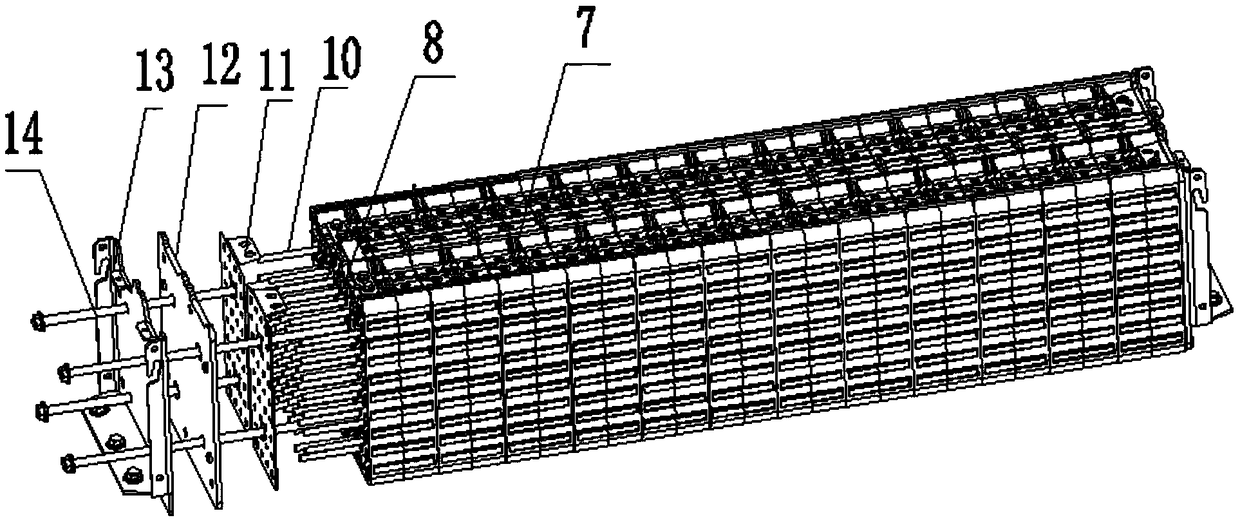

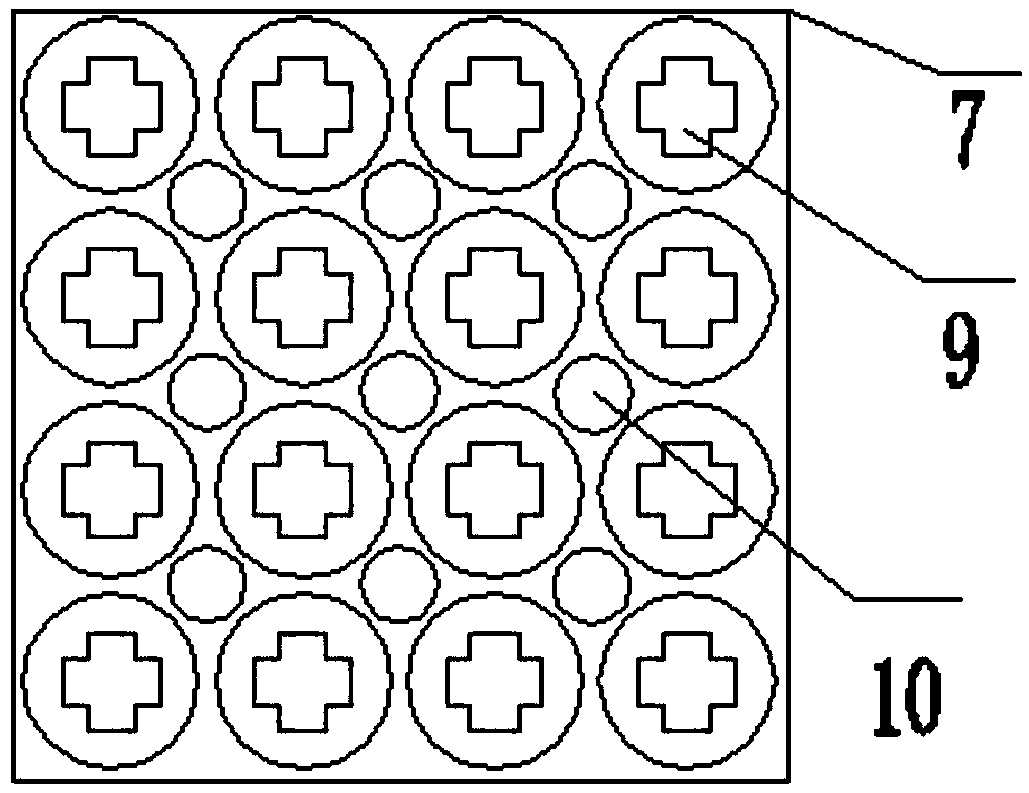

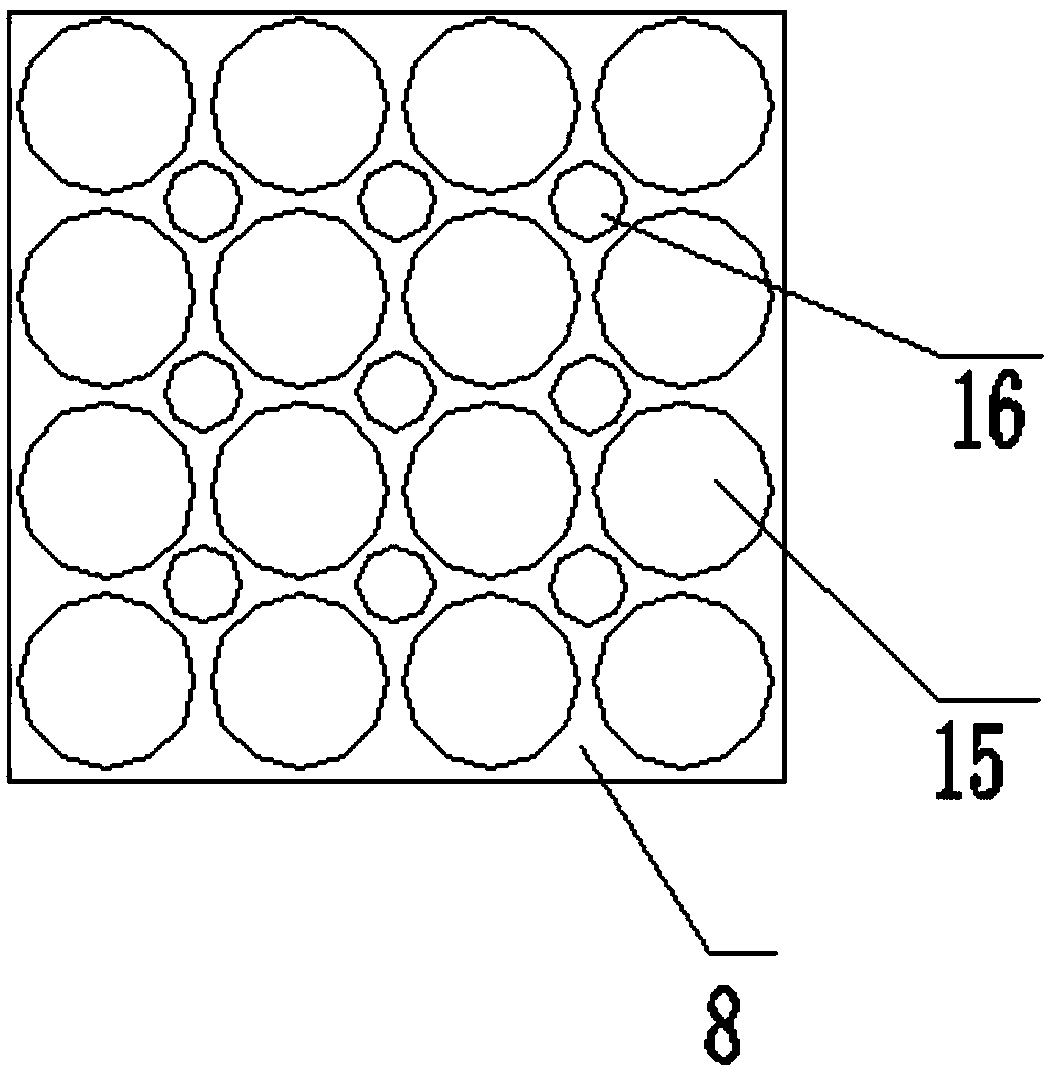

The invention relates to a battery module with automatic temperature equalization, which includes a shell, a battery cell bracket, a battery cell, a heat dissipation aluminum tube, a copper current carrier, an insulating plate, a fixed steel frame and a screw rod, and the battery cells are stacked in multiple layers It is arranged in the shell, and a heat-dissipating aluminum tube is arranged between every four batteries distributed in a square shape. The battery support is provided with a number of battery support holes and a number of aluminum tube support holes. The battery support holes and The distribution of the supporting holes of the aluminum tube is the same as the distribution of the electric core and the heat-dissipating aluminum tube respectively, and the copper current carrier, the insulating plate and the fixed steel frame are all provided with a number of supporting holes for the aluminum tube, and the support of the electric core passes through the electric core The heat dissipation aluminum tube is fixed in the housing, and the copper current carrier, insulating plate and fixed steel frame pass through the heat dissipation aluminum tube from inside to outside in sequence, and are fixed on the housing by screws; The liquid cavity is filled with cooling liquid, and the heat exchanging end is a tapered structure, which has good heat dissipation effect, low cost, high sealing level and high safety.

Description

technical field [0001] The invention relates to a battery module, in particular to an automatic temperature equalizing battery module. Background technique [0002] At present, there are many heat dissipation solutions for battery packs, such as natural cooling, air cooling, liquid cooling, etc. [0003] 1. Natural cooling is to dissipate heat from the battery pack through the wind generated during the driving process of the car. The effect is not obvious, especially in hot areas, and it has little effect. [0004] 2. The air-cooling system uses the wind from the air conditioner to dissipate the heat inside the battery pack. However, there must be vents, so that the sealing level of the battery pack cannot reach IP67, and the safety will be reduced. [0005] 3. The effect of the liquid cooling system is the best. The cost of the entire cooling system is relatively expensive. The existing liquid cooling system requires liquid to enter and exit, the sealing level will also de...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M2/10H01M10/613H01M10/617H01M10/625H01M10/6557H01M10/6567H01M10/6568H01M50/204

CPCH01M10/613H01M10/617H01M10/625H01M10/6557H01M10/6567H01M10/6568H01M2220/20H01M50/20Y02E60/10

Inventor 叶舰史云福黎艾

Owner 镇江润安管理咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com