Grinding device for profile tolerance and roughness of large joint ball

A grinding device and profile technology, applied in grinding devices, grinding machine tools, grinding machines, etc., can solve the problem that the grinding profile cannot be guaranteed, and achieve the effect of improving production efficiency and ensuring production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

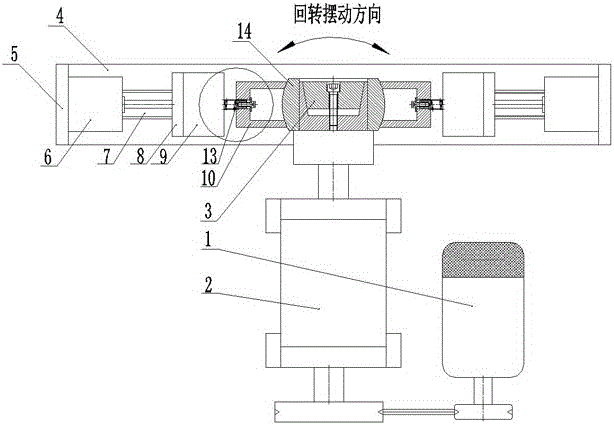

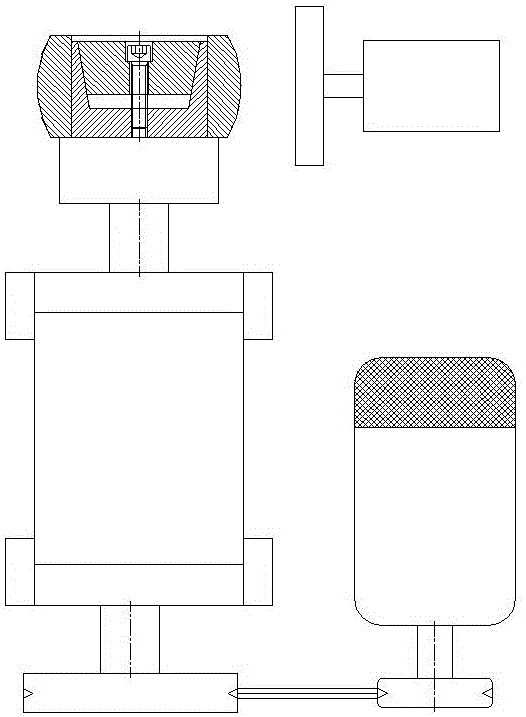

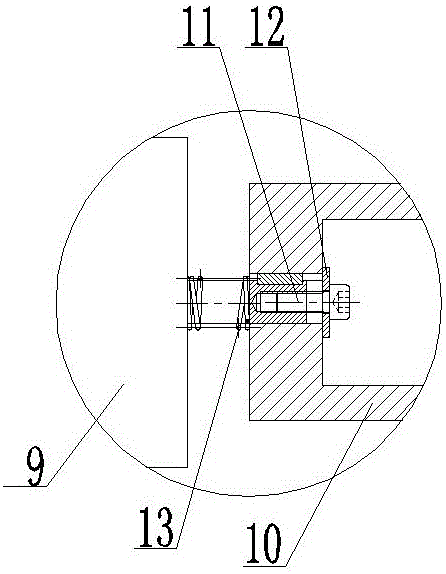

[0019] see Figure 1~Figure 6 , the present invention relates to a large joint ball profile roughness grinding device, which includes a main motor 1, a spindle box 2, an inner expansion sleeve 3, a rotary swing bracket 4 and two groups of grinding assemblies, the output end of the main motor 1 Connect the input end of the spindle box 2, the output end of the spindle box 2 protrudes upwards, the output end of the spindle box 2 is connected with an inner expansion sleeve 3 through a flange, and a large joint ball is set on the inner expansion sleeve 3 14. As a preference, the inner expansion sleeve 3 includes an inner expansion sleeve seat 3.1 and an inner expansion sleeve embedding block 3.2. A downward embedding groove is opened on the upper surface of the inner expansion sleeve seat 3.1. Firstly, the large joint The ball 14 is set outside the inner expansion sleeve 3.1, and then the inner expansion sleeve embedding block 3.2 is embedded in the embedding groove of the inner ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com