Self-balancing winding device for enameled wires

A winding device and self-balancing technology, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material handling, etc., can solve problems such as deformation, fracture, cracking of the enamel layer of the enameled wire, etc., to improve the quality, simple structure, Easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

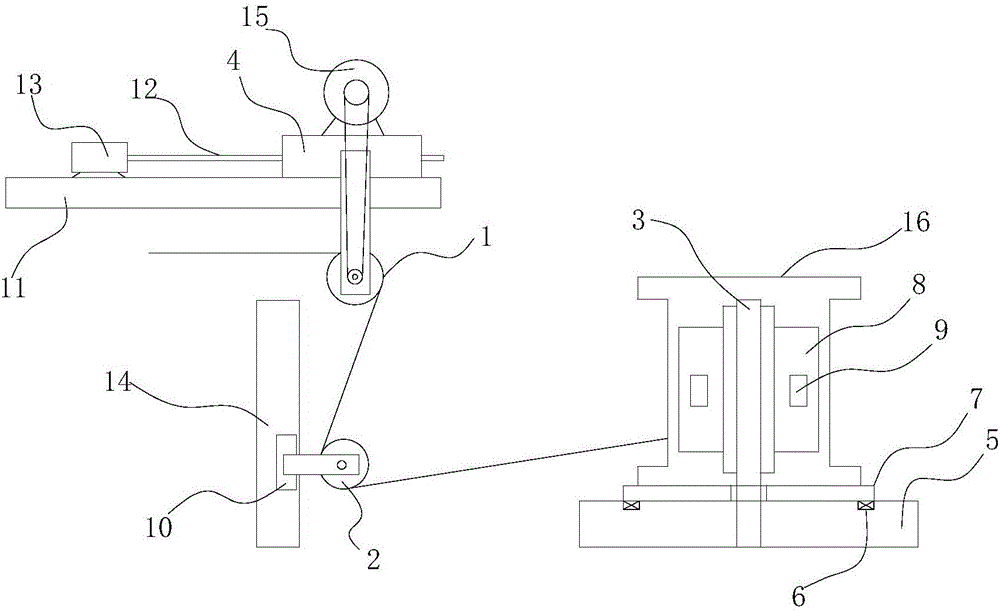

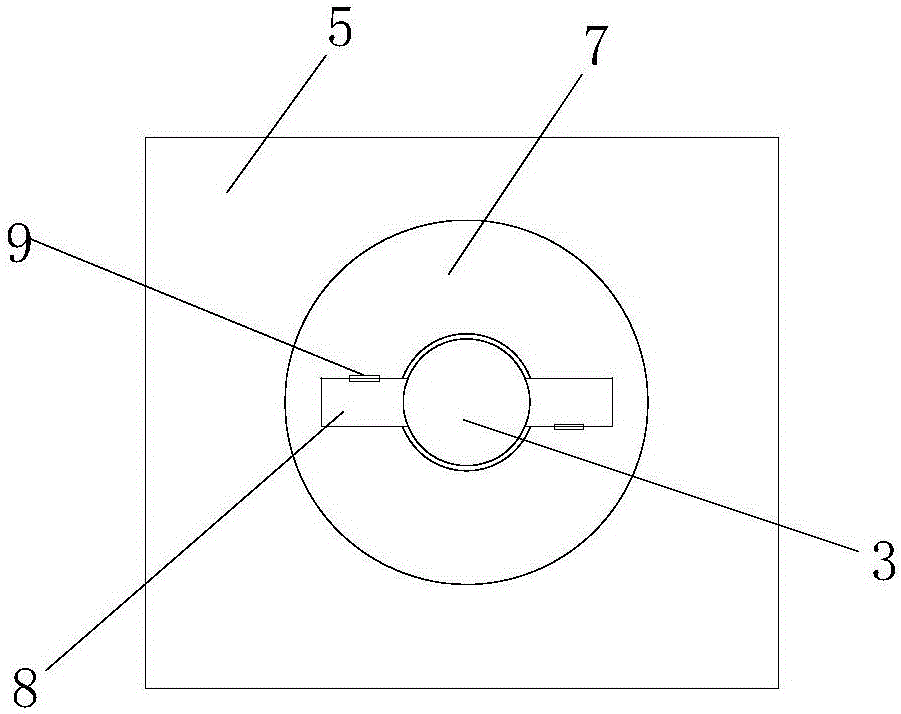

[0013] Example. An enameled wire self-balancing winding device, such as figure 1 and figure 2 Shown: including wire feeding roller 1, wire roller 2 and take-up shaft 3; It is arranged on the base 5 on which the driving motor is installed, and the base 5 is equipped with a horizontal tray 7 through the plane bearing 6, and the center of the horizontal tray 7 is provided with an opening for accommodating the rewinding shaft 3; the rewinding shaft 3 is provided with a vertical limit fin Sheet 8, and the side wall of the limiting fin 8 is provided with a piezoelectric ceramic sheet 9. Described horizontal movement support 4 is arranged on the horizontal slide rail 11, and the center of horizontal movement support 4 is perforated with screw rod 12, and the rotating shaft of screw rod 12 ends and tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com