A Non-Uniform Microstrip-to-Stripline Transition Structure

A transitional structure and microstrip line technology, applied in the direction of waveguides, electrical components, connecting devices, etc., can solve the problem that the structure cannot be applied to the non-uniform microstrip line structure, etc., to improve standing wave characteristics, strong flexibility, and application occasions. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

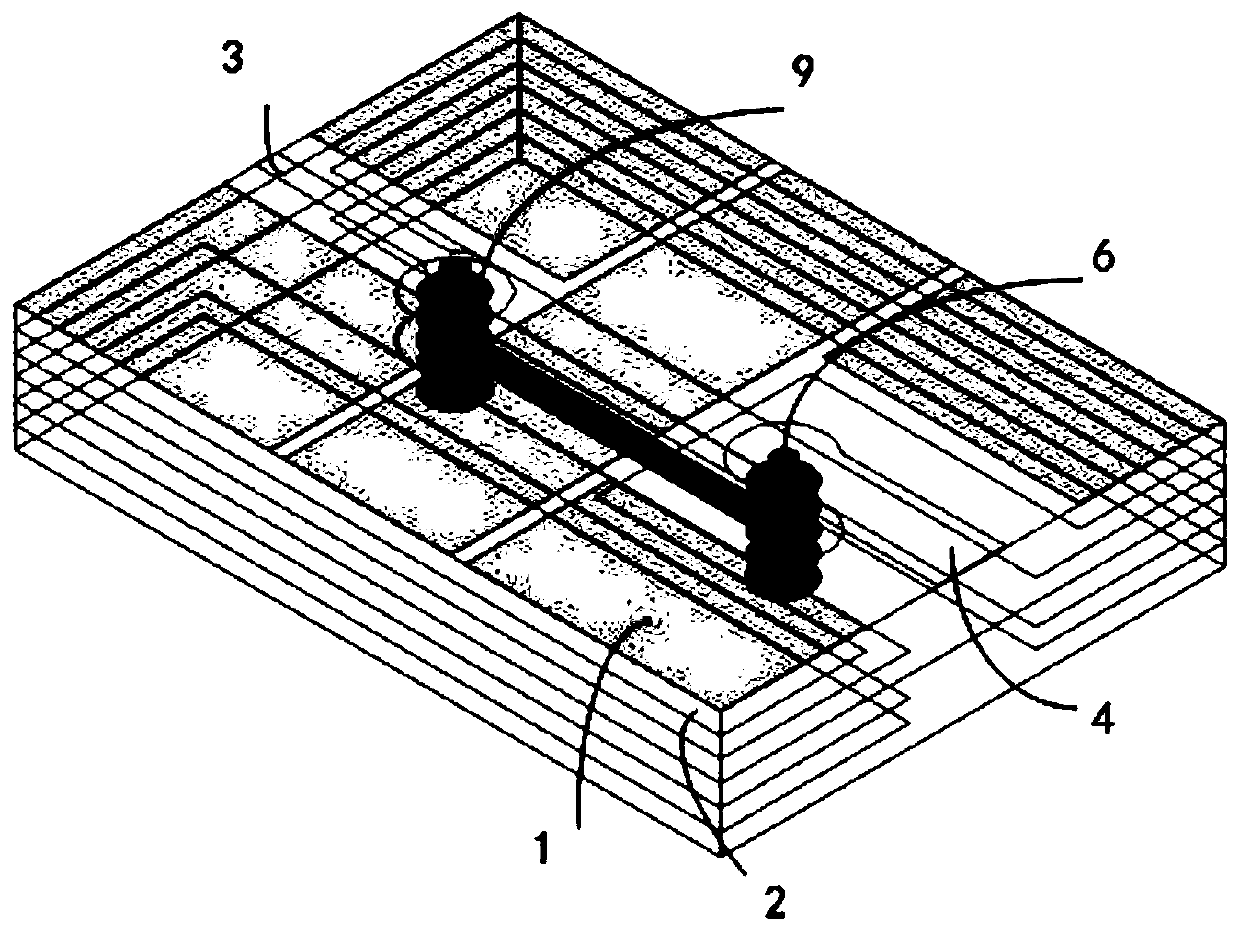

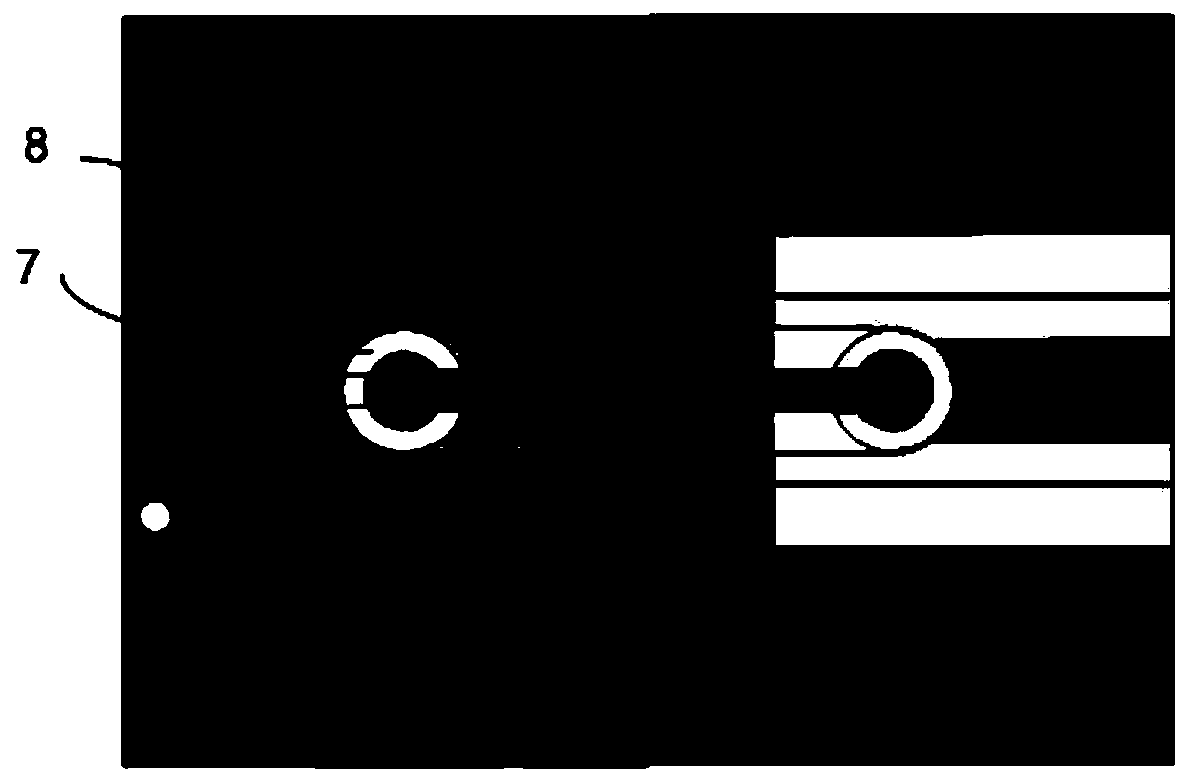

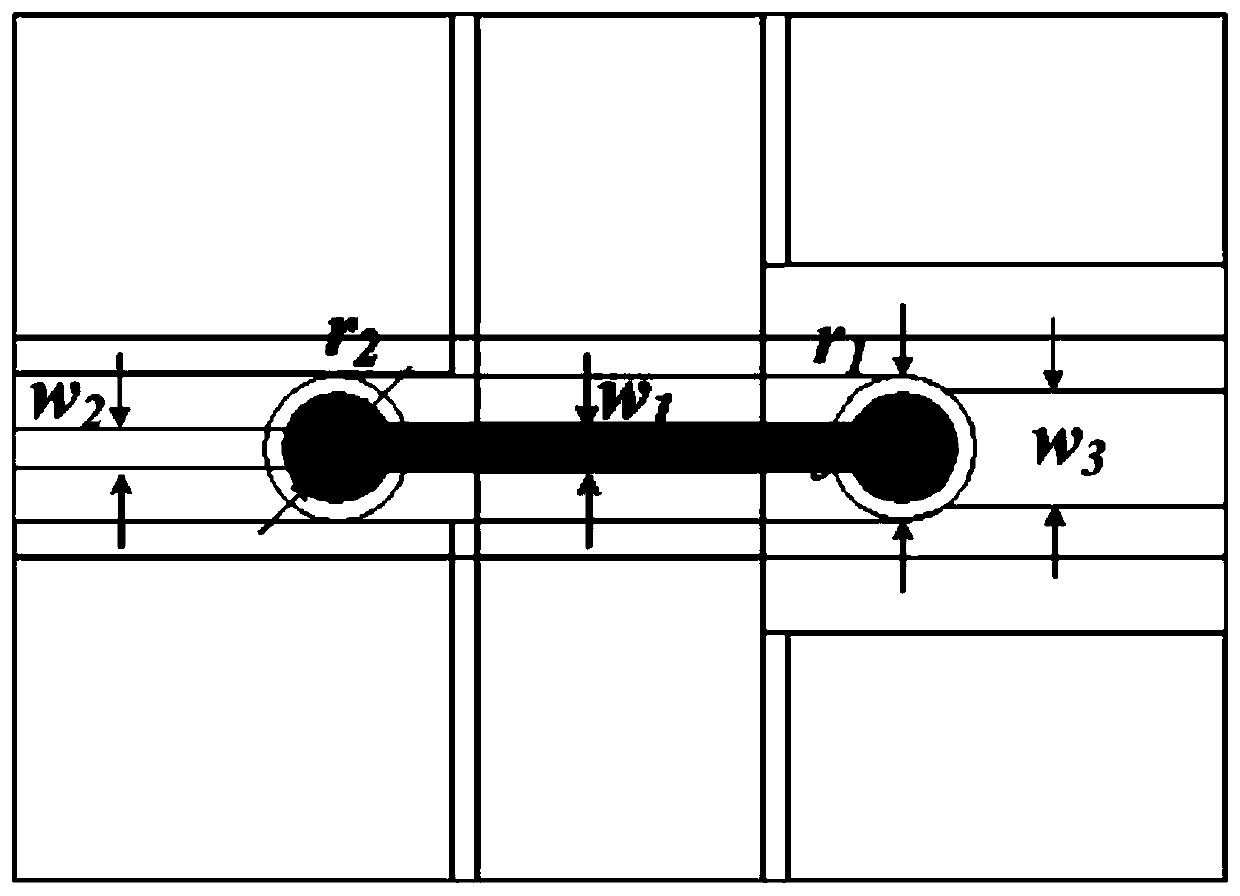

[0034] to combine Figure 1-Figure 7 , the non-uniform microstrip line to stripline transition structure of the present invention is described in detail, which includes: a metal layer and a dielectric layer, the number of metal layers is N, N≥4, N layers of metal layers are stacked in sequence, and the dielectric layer The number of layers is N-1, and the dielectric layer is set between every two adjacent metal layers; it also includes: non-uniform input microstrip lines, non-uniform output microstrip lines, striplines, circular slots, and signal blind holes ; The non-uniform input microstrip line and the non-unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com