Hull structure with excellent collision resistance and design method of hull structure

A design method and structure technology, applied in the direction of hull design, hull, hull deck, etc., can solve the problems of increased operating costs and reduced loading efficiency, and achieve excellent collision resistance and significant contribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

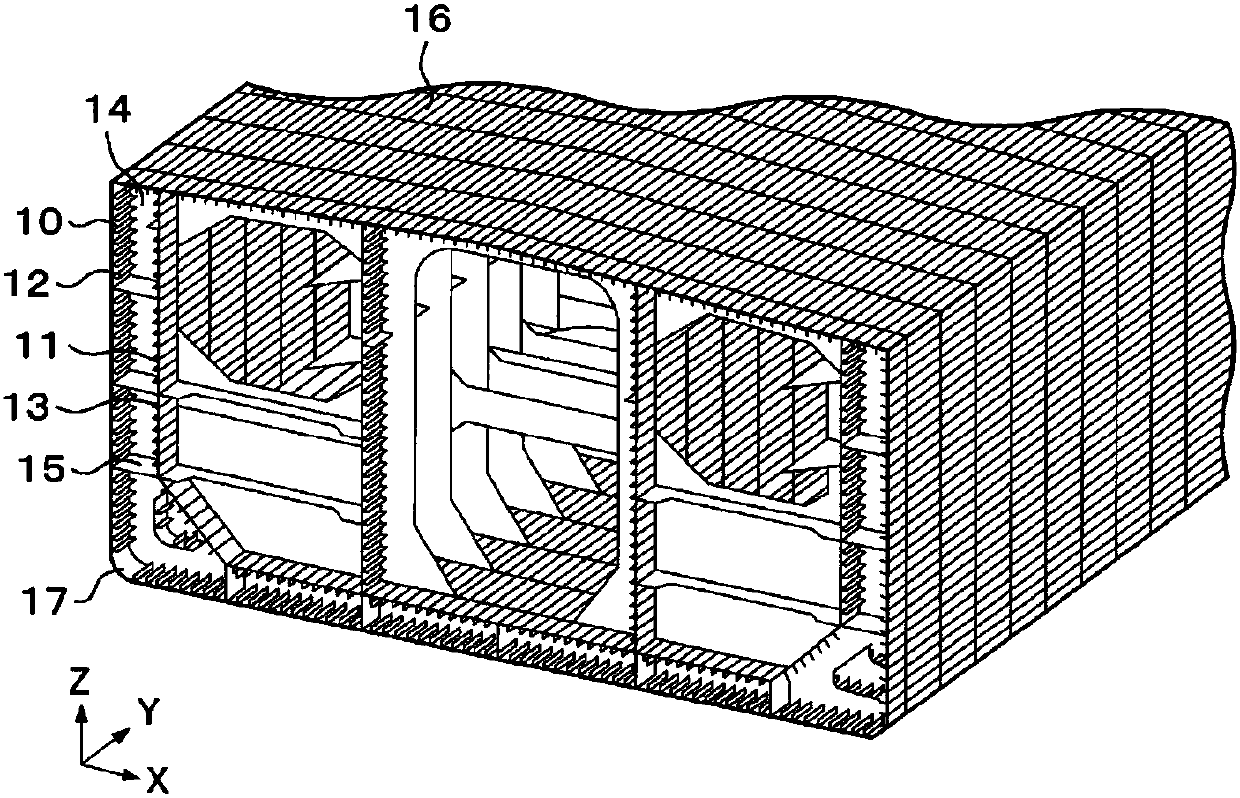

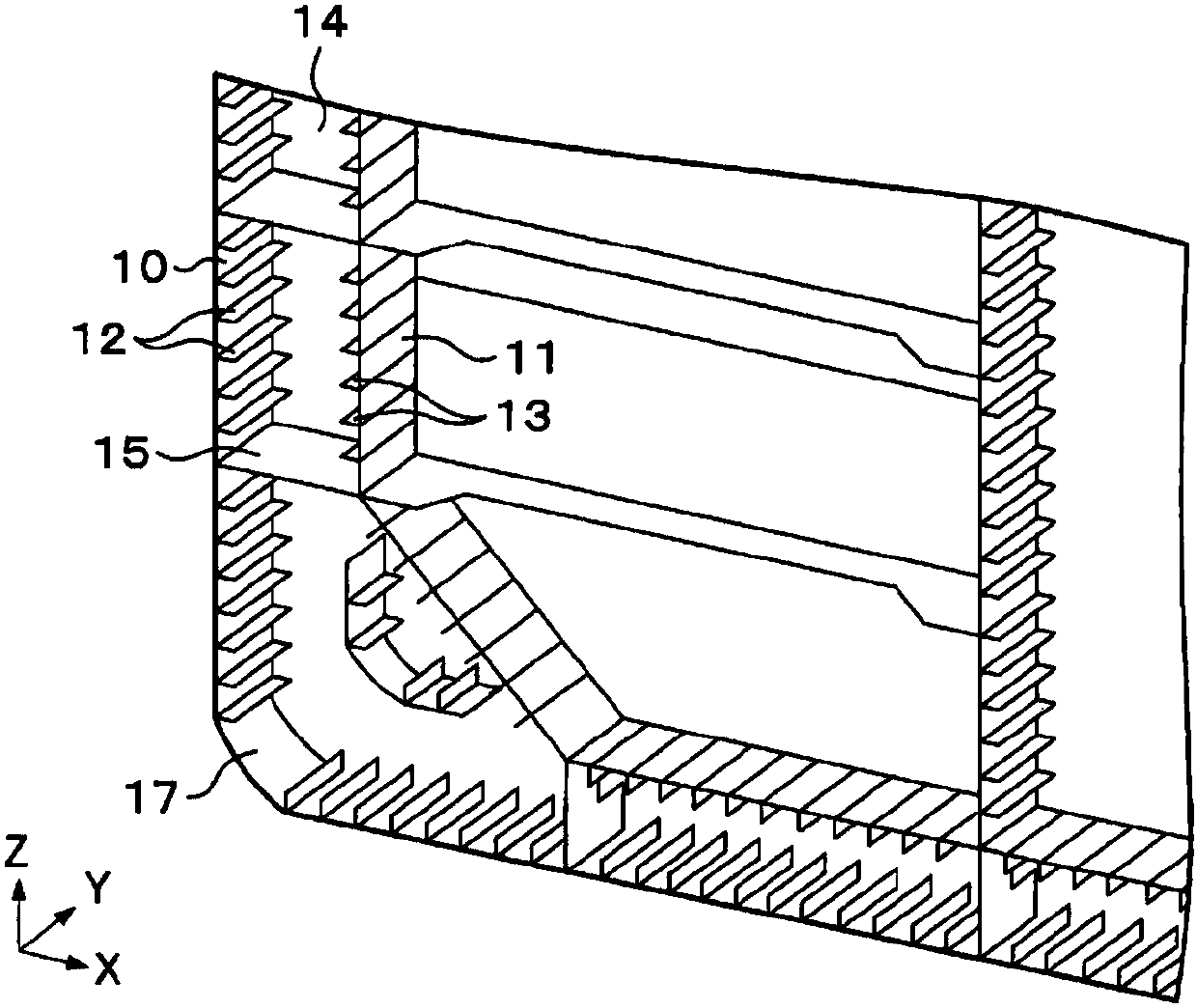

[0099] First, the effect when the present invention is applied to a double hull structure (double hull) is explained. in figure 1 In the components shown, it is assumed that the outer and inner plates, as well as the deflection prevention parts attached to the outer and inner plates, use the total extension specified in the Unified Requirement W11 of the International Association of Classification Societies (IACS) In the case of a steel plate with a total elongation of 1.5 times the value of the elongation, image 3 In the collision scenario shown, the damage of the inner panel is analyzed using FEM. The result is clear, such as Picture 11 As shown, the cracks and large breaches of the inner plate have not been developed.

Embodiment 2

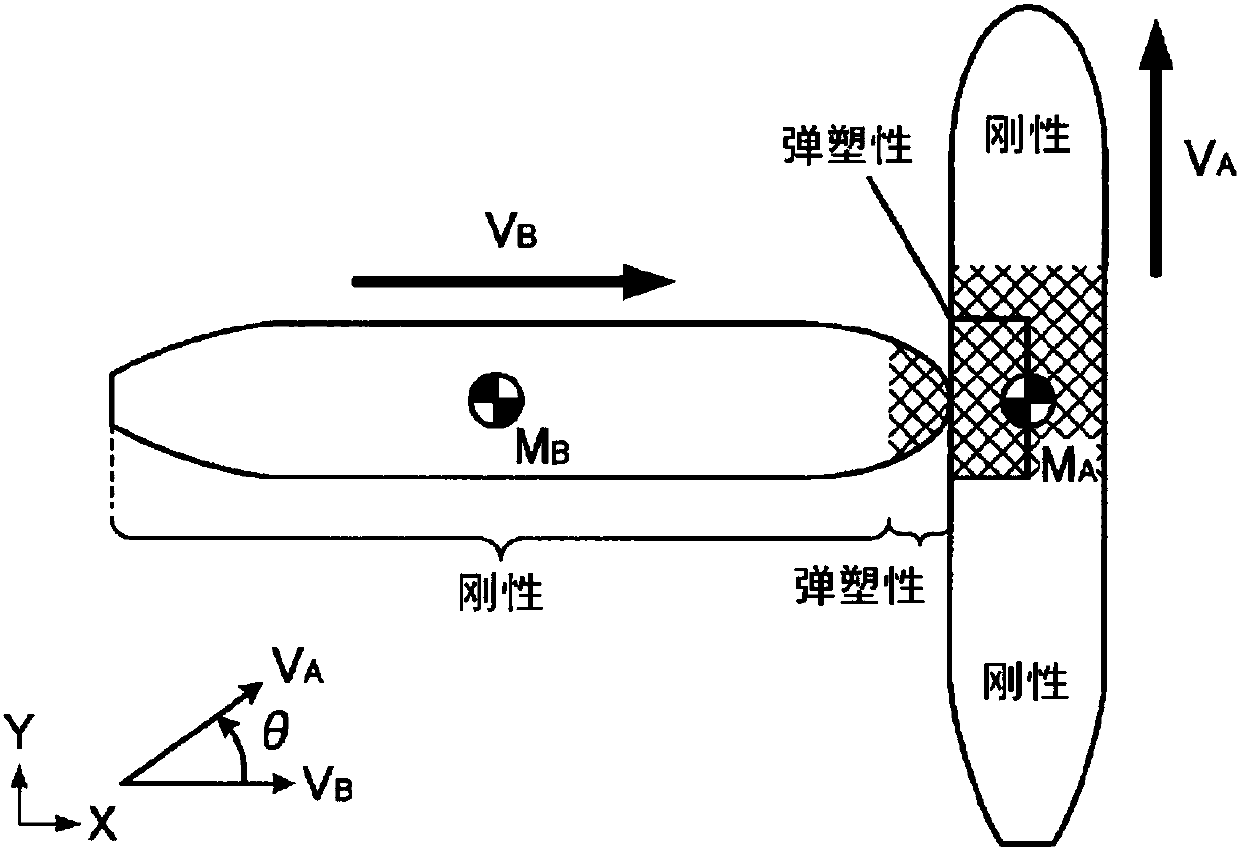

[0101] Next, the effect when the present invention is applied to a single-layer hull structure (single-layer hull) will be described. The inventor assumes that the VLCC collided with a single-hull bulk carrier, and used FEM to obtain the deformation of the bulk carrier's components and the energy absorbed by the deformation.

[0102] In FEM analysis, such as image 3 As shown, it is assumed that a VLCC self-stopping bulk carrier (V A =0kt), the front side near the center of the hull is in a serious collision at 12kt at 90 degrees. Specifically, such as Picture 12 As shown, the bow of the VLCC was made to collide with the outer plate 20 of a bulk carrier with a single-layer hull structure, and the analysis was performed until 6 seconds after the collision. The collision position is assumed to be a more severe collision position relative to the breach of the outer panel. In addition, in Picture 12 , The starboard half of the bulk carrier is not shown.

[0103] Then, for the case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com