Power distribution cabinet capable of cleaning dustproof screen automatically

A technology for automatic cleaning and power distribution cabinets, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of wire mesh contamination, equipment failure, affecting heat dissipation, etc., to avoid equipment failure. , Low manufacturing cost, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

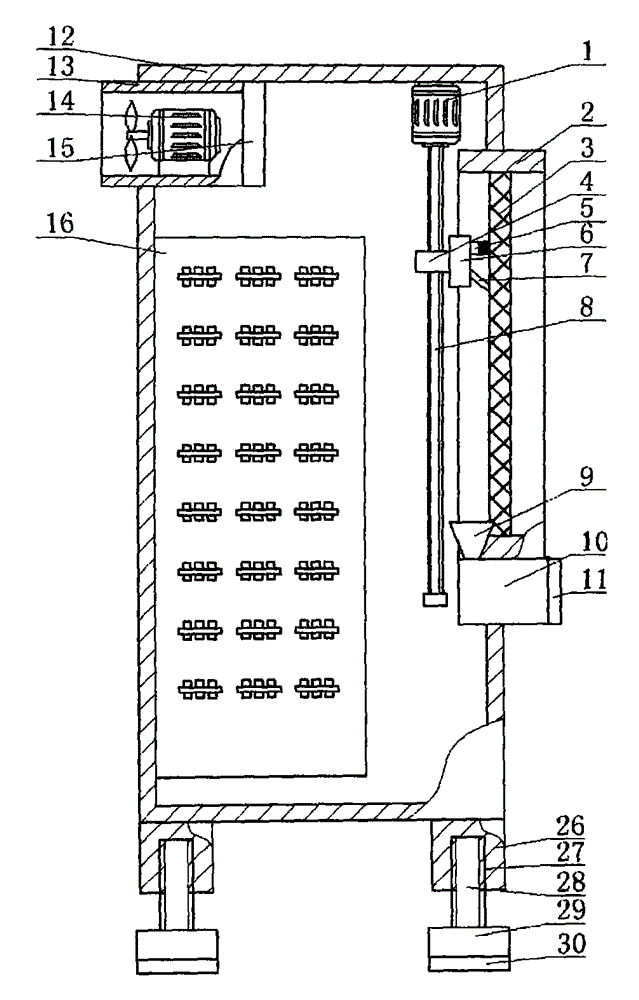

[0012] A self-cleaning dust-proof wire mesh power distribution cabinet, such as figure 1 As shown, it includes a power distribution cabinet 12, and a fixed shell 2 is installed on the side of the power distribution cabinet 12. The fixed shell 2 is a rectangular parallelepiped shell with openings on both sides. Stepping motor 1, the output shaft of stepping motor 1 is installed with screw rod 8, nut 4 is installed on screw rod 8, slider 6 is installed on one side of nut 4, slider 6 cooperates with fixed shell 2, one side of slider 6 Install the brush 5 and the spatula 7, the bristles of the brush 5 cooperate with the dust-proof screen 3, the blade of the spatula 7 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com