Tool wear monitoring method based on multi-sensor current signals

A current signal, multi-sensor technology, used in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of less tool processing data, machine tool failure, tool waste, etc., to solve the problem of less processing data and realize processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

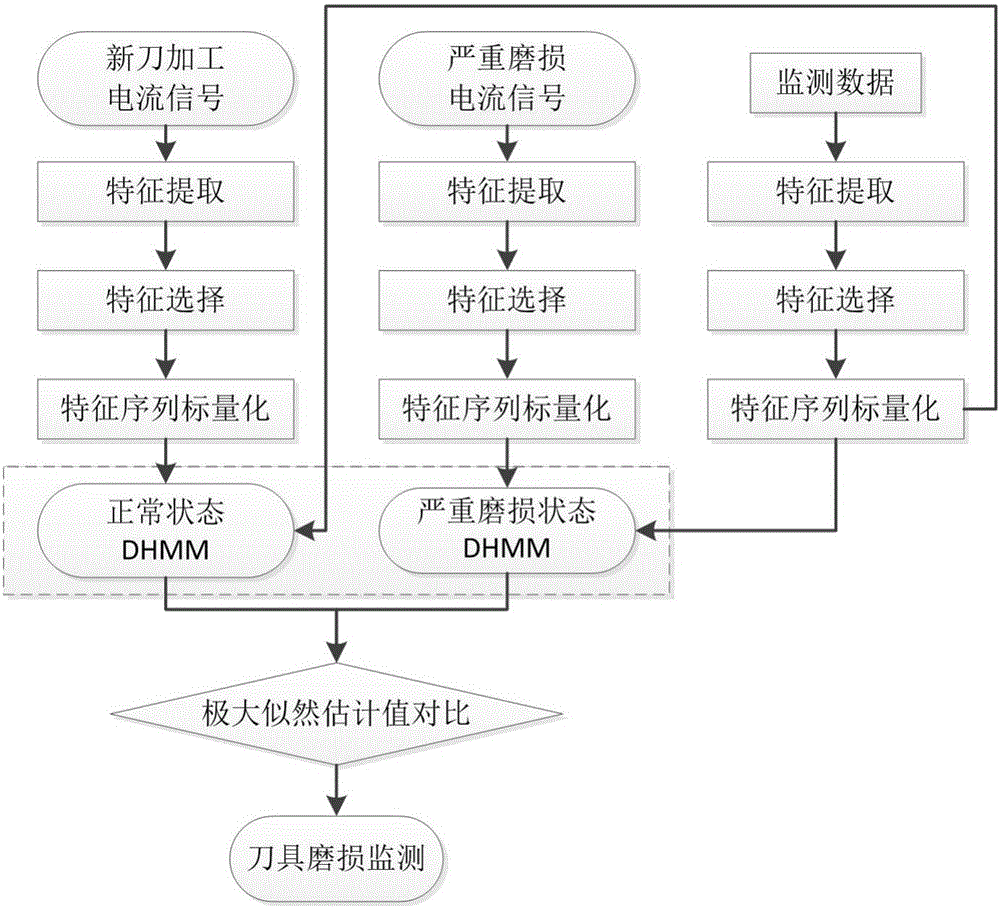

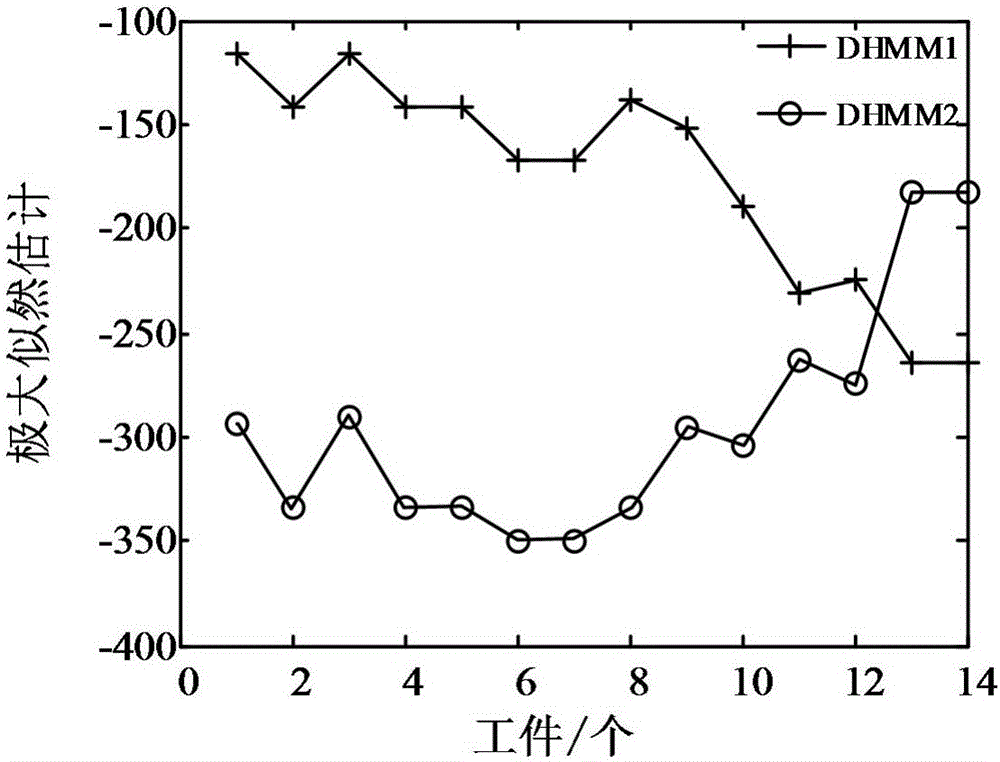

[0043] refer to figure 1 , a tool wear monitoring method based on multi-sensor current signals, comprising the following steps:

[0044] The first step is to clamp the current sensors on the motor live wires of different axes of the machine tool at the same time, and use the current sensors to collect the motor current signals of different axes during the machining process of the tool; collect the multi-sensor currents of N workpieces before a new tool is processed. The signal is used to construct the discrete hidden Markov model of the normal state of the tool; the multi-sensor current signal of the severe tool wear is collected to construct the discrete hidden Markov model of the severe tool wear state;

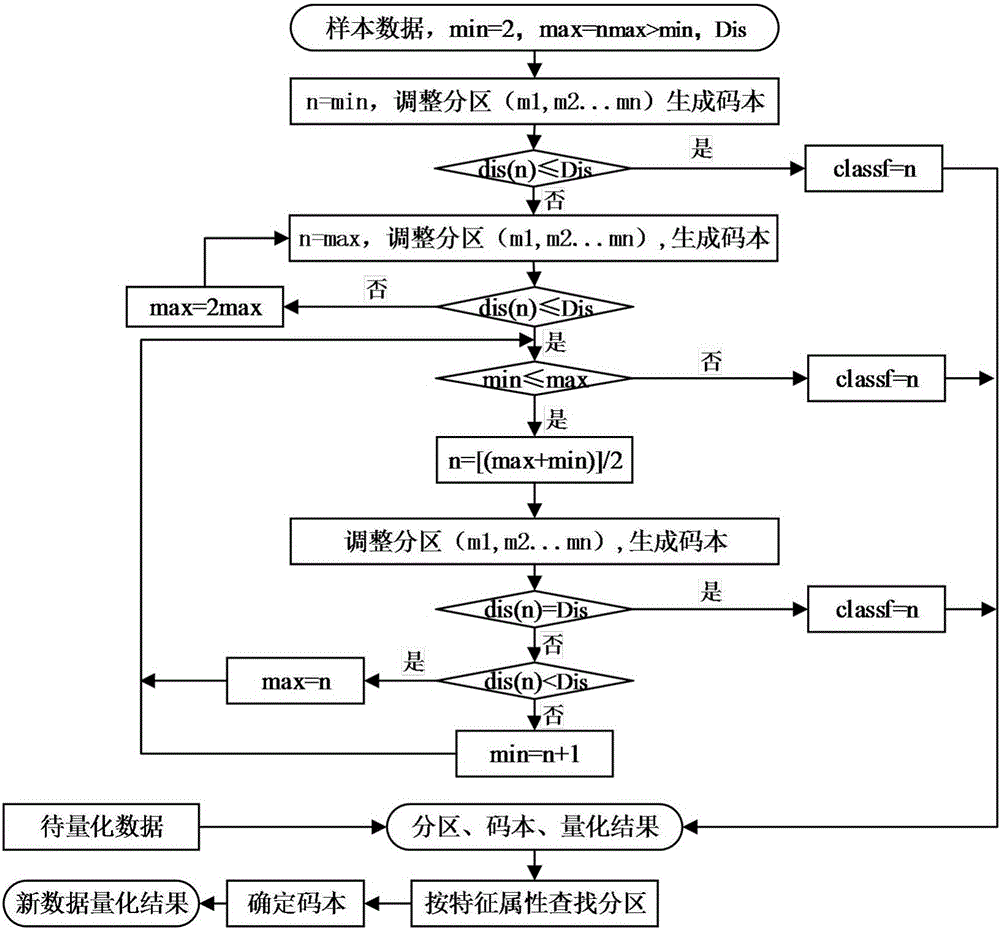

[0045] The second step is to use time domain analysis and wavelet packet energy spectrum analysis to extract features of the current signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com