Method for constructing diamond milling and grinding head state monitoring system for machining ceramic mobile phone backboard

A condition monitoring system and ceramic backplane technology, applied in stone processing equipment, stone processing tools, metal processing equipment, etc., can solve problems such as waste of tools, limited accuracy of workers' judgment, impact on production efficiency, etc., and achieve increased redundancy Accuracy and fault tolerance, ensuring rapidity and correctness, and improving the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

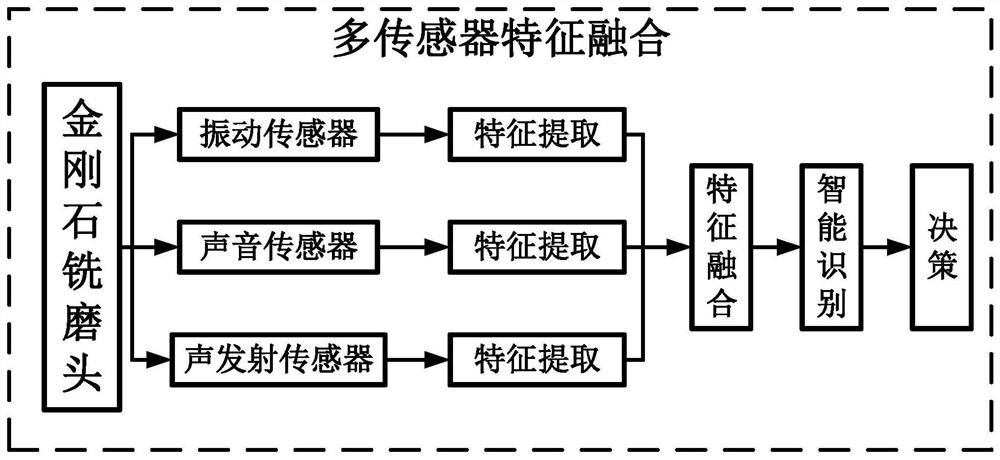

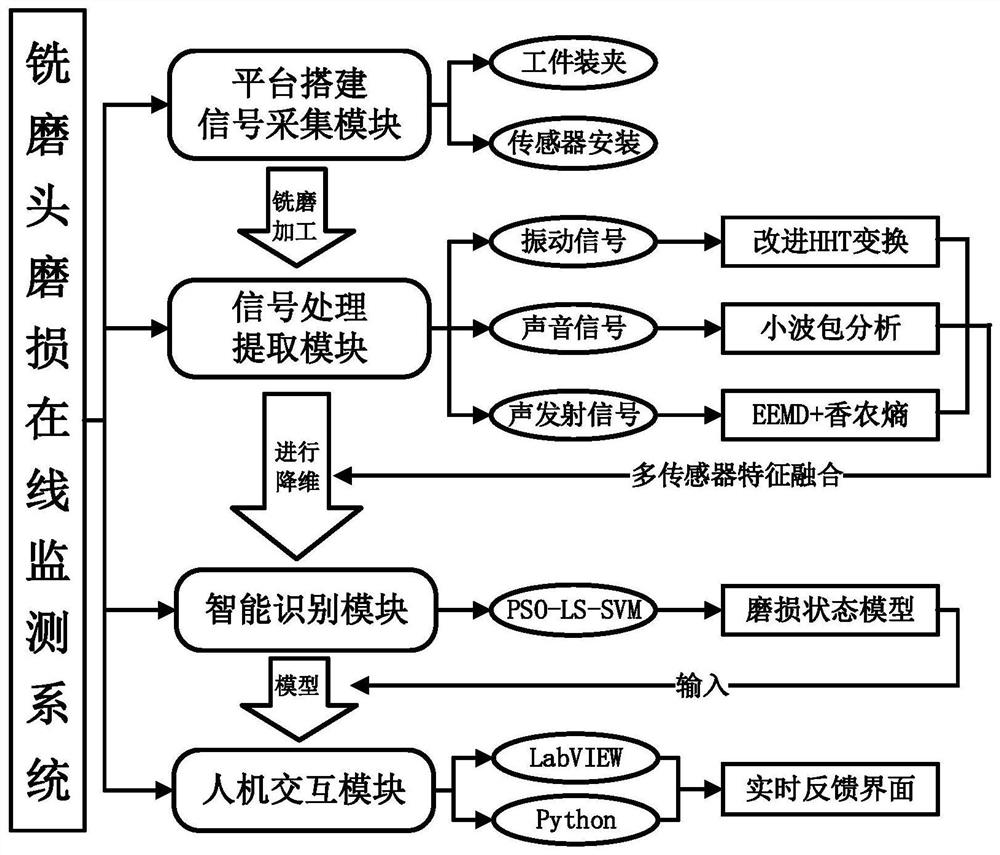

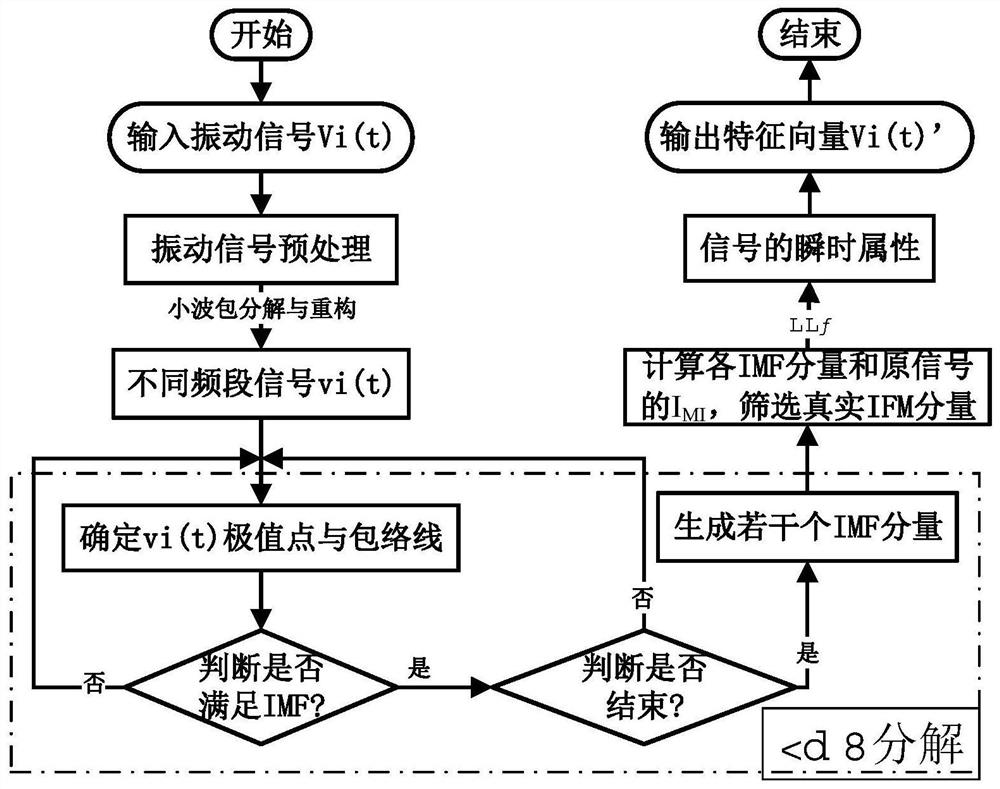

[0058] A diamond milling and grinding head tool wear state monitoring system for processing mobile phone ceramic backplane, refer to Figures 1 to 5 , including its processing platform, the wear signal acquisition module of the milling head; the signal processing and feature extraction module of the wear process; the intelligent decision-making module and the human-computer interaction module for online real-time feedback of the wear of the milling head.

[0059] The processing platform and the wear signal acquisition module of the milling head are based on the environment of the processing process and the characteristics of the sensor itself, the ceramic blank is fixed with a vacuum chuck, and the acceleration sensor, the sound sensor and the acoustic emission sensor are installed with special fixtures such as a magnetic base. sensor. Then co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com