Labor-saving stapler

A stapler and outer cover technology, applied in the direction of nailing staple tools, manufacturing tools, etc., can solve the problems of complex connection relationship, increase the manufacturing cost of staplers, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

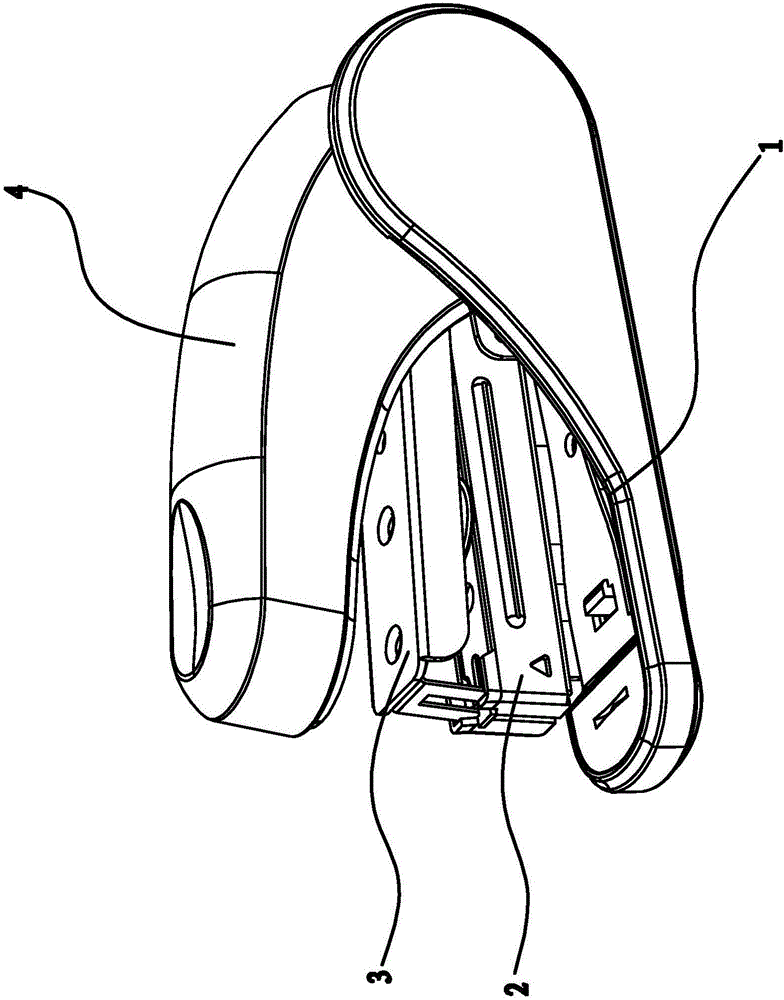

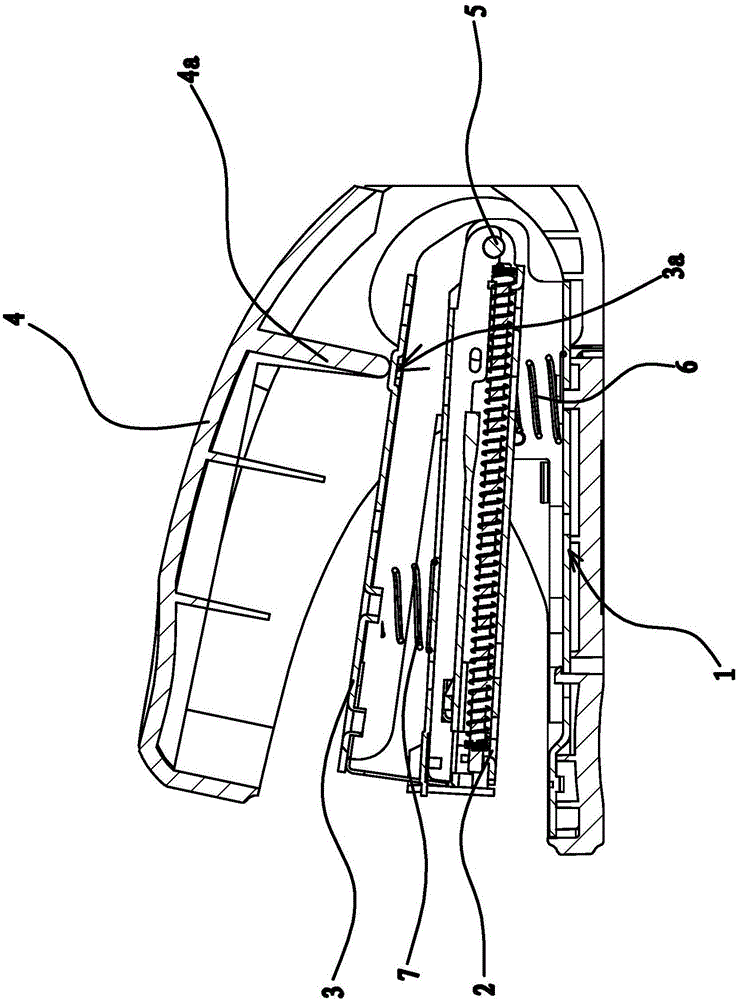

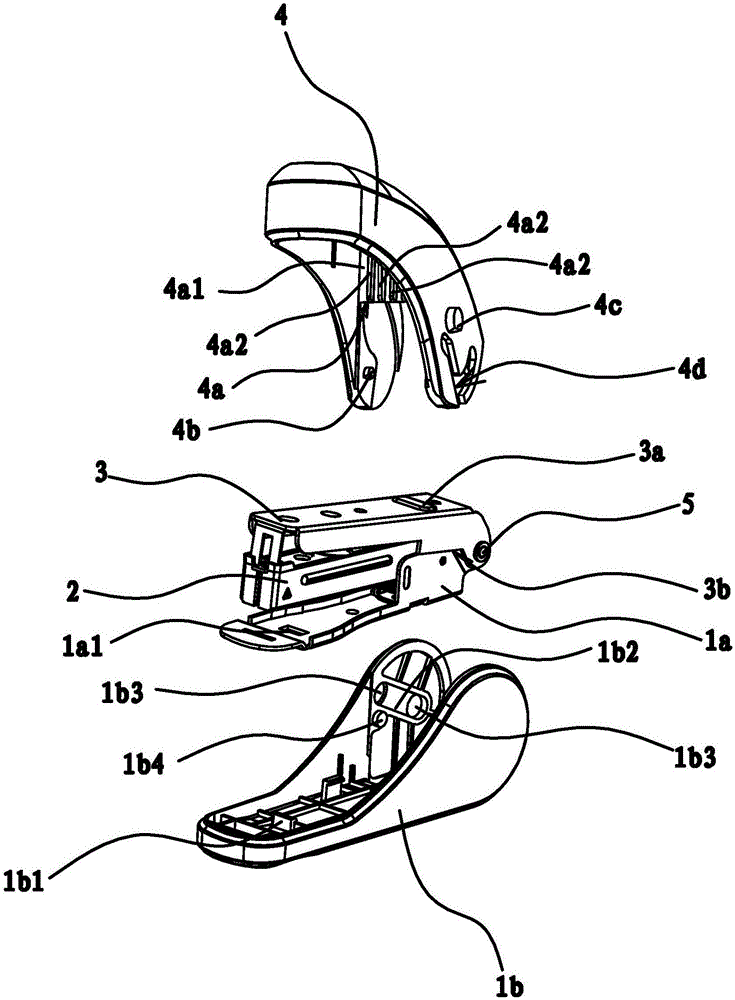

[0041] Such as figure 1 , figure 2 and image 3 As shown, the labor-saving stapler includes a bottom cover 1, a nail box 2, a press box 3, and an outer cover 4. The bottom cover 1 includes a bottom plate 1a and a plastic bottom 1b. The plastic bottom 1b has an upwardly protruding block 1b1, and the bottom plate A slot 1a1 is opened on 1a corresponding to the position of the block 1b1, and the block 1b1 is snapped into the slot 1a1 and buckled on the bottom plate 1a so that the floor is fixed on the plastic bottom 1b. The inner end of the nail box 2 and the inner end of the bottom plate 1a are hinged by the rear pin 5, and the inner end of the pressure box 3 is also hinged by the rear pin 5 and the inner end of the bottom plate 1a. There is a reset mechanism between the nail box 2 and the bottom plate 1a. A spring one 6, a return spring two 7 is arranged between the pressing box 3 and the nail box 2.

[0042] Such as image 3 , Figure 4 and Figure 5 As shown, the inner...

Embodiment 2

[0053] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the upper surface of the raised portion 3a is a circular arc surface, and the action portion 4a includes a top inner wall formed by the inner end of the outer cover 4. The pressing plate 4a1 protruding downwards and several ribs 4a2 distributed on the side of the pressing plate 4a1 near the outer end of the outer cover 4, the lower surface of the pressing plate 4a1 and the ribs 4a2 are connected to form a flat slope, and the upper surface of the raised portion 3a is set The arc surface and the lower surface of the action part 4a are set as slopes, and when the action part 4a acts on the raised part 3a, it is ensured that the action part 4a and the raised part 3a will not interfere with each other, so that the outer cover 4 The pressing down of the pressing box 3 can be realized smoothly through the cooperation of the action part 4a and...

Embodiment 3

[0055] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the linkage structure includes a stopper protruding from the inner side of the pressure box 3 and a stopper protruding from the inner end of the outer cover 4 The stopper on the inner wall, the stopper is located below the stopper head. When the outer end of the outer cover 4 is constantly opened outwards relative to the bottom cover 1, the stopper will swing to the lower side of the stopper against the inner end of the pressure box 3 along with the inner end of the outer cover 4, so that the stopper and The stoppers form against each other, and during the further outward opening process of the outer end of the outer cover 4 relative to the bottom cover 1, the stopper drives the pressure box 3 to turn outwards around the hinge point of the pressure box 3 and the bottom cover 1 , so that the labor-saving stapler can still have the func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com