Transmission belt forming hub

A technology for driving belts and forming surfaces, applied in belts, other household appliances, household appliances, etc., can solve problems such as leakage, difficulty in demoulding, affecting the production quality and production efficiency of rubber sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through specific embodiments.

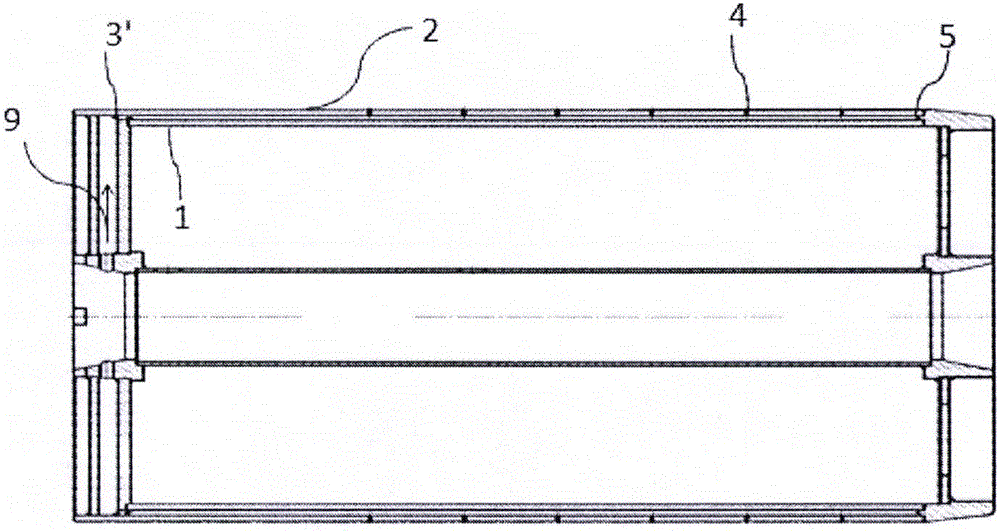

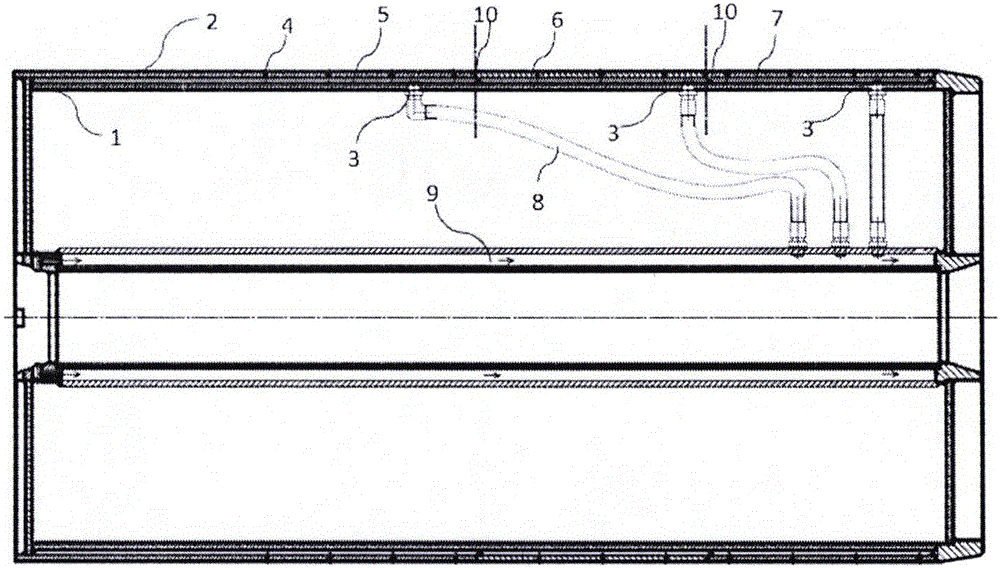

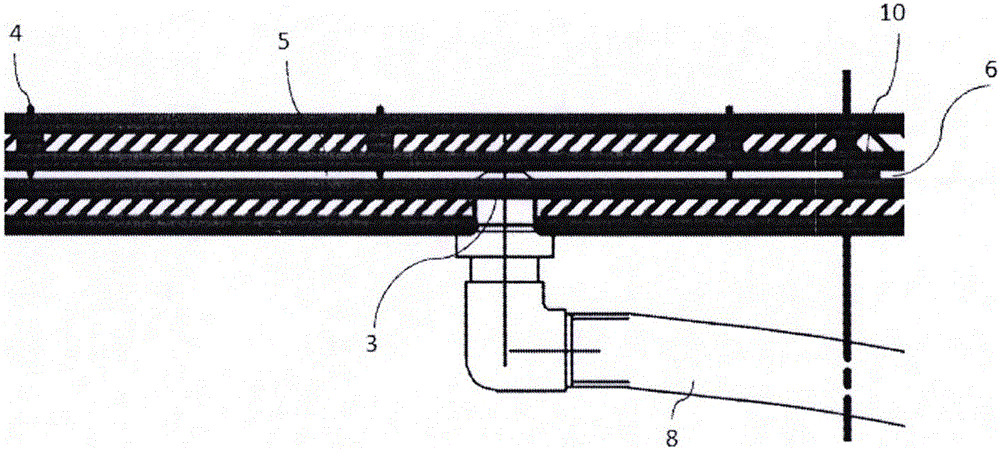

[0018] Such as figure 2 As shown, the transmission belt molding hub includes a skeleton 1, a molding surface 2, and a cavity formed between the skeleton and the molding surface by the outer wall of the chamber, the inner wall of the chamber, and the side wall of the chamber. There are several air holes on the surface 2, the inner wall of the chamber has air inlet holes, the outer wall of the chamber has air outlet holes, and the air outlet holes of the chamber and the corresponding air holes on the forming surface can communicate with each other. The skeleton includes a cylindrical outer wall. In this specific embodiment, the inner wall of the chamber is the outer wall of the skeleton, the outer wall of the chamber is the molding surface of the forming hub, and the side wall of the chamber can be the radial surface of the skeleton. Since the chamber is composed of the skeleton and Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com