Preparation method of double-layer ribbed bi-color reinforced composite pipe

A color-enhanced, composite pipe technology, applied in the direction of tubular goods, other household appliances, household appliances, etc., can solve the problems of single color of composite pipe, no distinctive features, pipe deformation, etc., to achieve excellent lateral tensile force resistance, improve toughness The ability to break, the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

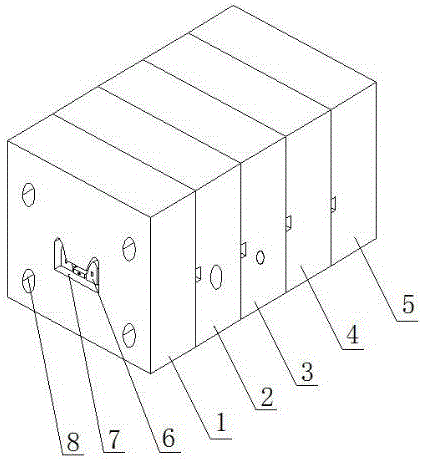

[0035] Example 1: A method for preparing a double-layer ribbed double-color reinforced composite pipe, comprising the following steps:

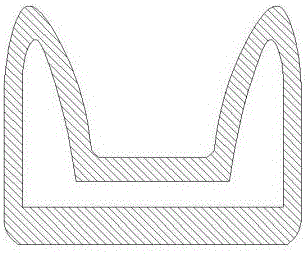

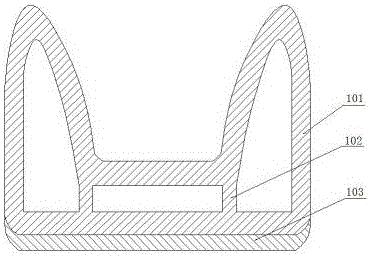

[0036] A. Utilize the first and second extruders to continuously extrude double-layer, double-color plastic special-shaped strips with tubular protrusions containing cavities through the extrusion die;

[0037] B. The special-shaped strips obtained in step A are spirally wound side by side on the continuously rotating forming drum, so that a gap is formed between the two tubular protrusions where adjacent plastic special-shaped strips are close to each other;

[0038] C. Utilize the third and fourth extruders to jointly and continuously extrude molten plastisol into the gap described in step B;

[0039] D. Apply facing pressure to two adjacent tubular protrusions next to the gap that has been squeezed into the plastisol, so that the two tubular protrusions are tightly fused into one, and the two tubular protrusions are welded to form a hollow...

Embodiment 2

[0043] Embodiment 2: A method for preparing a double-layer ribbed double-color reinforced composite pipe, comprising the following steps:

[0044] A. Utilize the first and second extruders to continuously extrude double-layer, double-color plastic special-shaped strips with tubular protrusions containing cavities through the extrusion die;

[0045] B. The special-shaped strips obtained in step A are spirally wound side by side on the continuously rotating forming drum, so that a gap is formed between the two tubular protrusions where adjacent plastic special-shaped strips are close to each other;

[0046] C. Utilize the third and fourth extruders to jointly and continuously extrude molten plastisol into the gap described in step B;

[0047] D. Apply facing pressure to two adjacent tubular protrusions next to the gap that has been squeezed into the plastisol, so that the two tubular protrusions are tightly fused into one, and the two tubular protrusions are welded to form a hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com