A manufacturing process of double-wall corrugated pipe modified by using waste hdpe

A double-wall corrugated pipe and production process technology, which is applied in the field of production process of double-wall corrugated pipe modified by waste HDPE, can solve the problems of lack of ring rigidity and ring flexibility, poor physical properties of pipe materials, and poor product quality. Achieve the effects of improved appearance, improved gloss and brightness, and improved ring flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

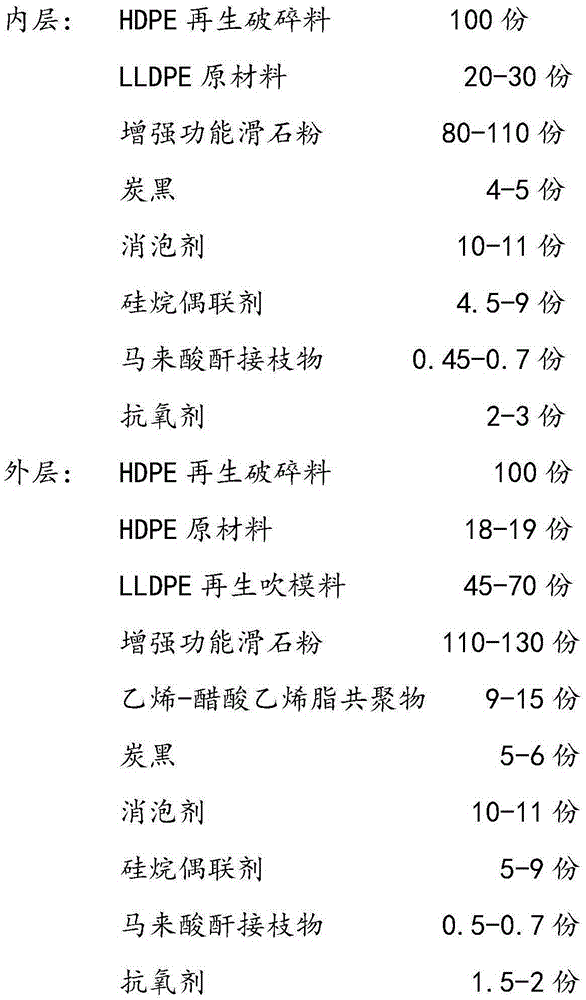

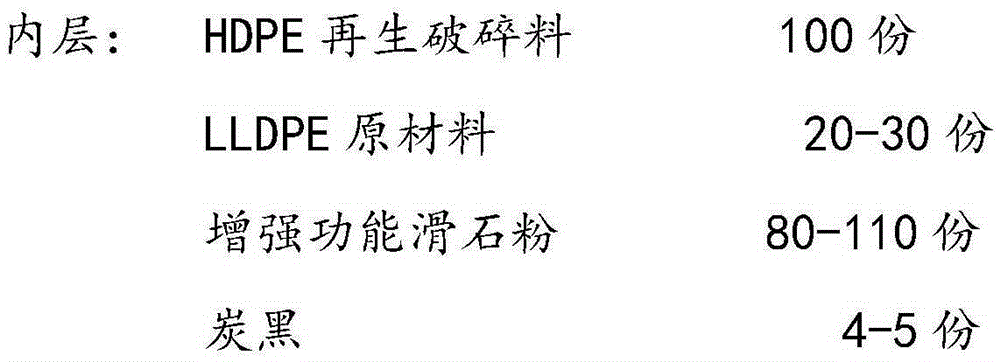

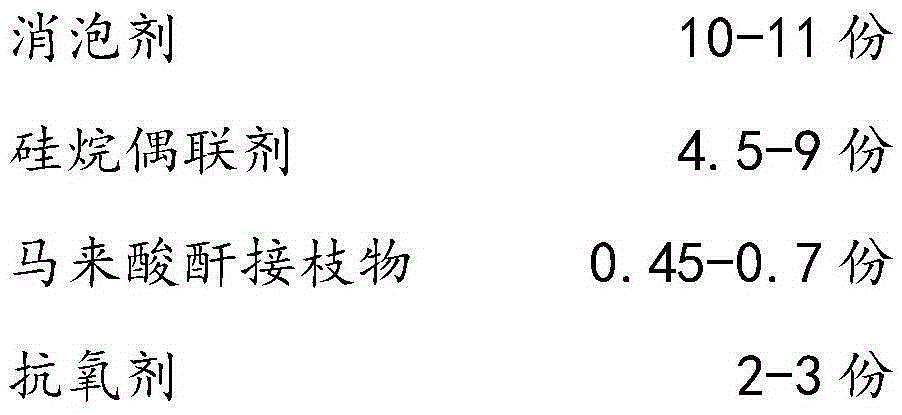

[0039] A double-wall corrugated pipe modified by using waste HDPE, the inner layer and the outer layer are mainly prepared from the following raw materials in parts by weight:

[0040]

[0041]

[0042]

[0043] Corresponding to the above-mentioned manufacturing process of using waste HDPE to modify the double-wall corrugated pipe, the process steps are as follows:

[0044] A) The production steps of the special material for the inner layer are as follows:

[0045] 1) Pour HDPE regenerated crushed material and LLDPE raw materials into a high-speed mixer and mix evenly (the speed of the high-speed mixer is controlled at 1000r / min), then add silane coupling agent at room temperature, and then add horse To the acid anhydride graft, after mixing evenly (mixing 3min), add enhanced function talcum powder and carbon black and mix evenly;

[0046]2) When the temperature of the mixture in the high-speed mixer reaches 36 degrees, add defoamer and mix evenly. When the temperatu...

Embodiment 2

[0054] A double-wall corrugated pipe modified by using waste HDPE, the inner layer and the outer layer are mainly prepared from the following raw materials in parts by weight:

[0055]

[0056]

[0057]

[0058] Corresponding to the above-mentioned manufacturing process of using waste HDPE to modify the double-wall corrugated pipe, the process steps are as follows:

[0059] A) The production steps of the special material for the inner layer are as follows:

[0060] 1) Pour HDPE regenerated crushed material and LLDPE raw materials into a high-speed mixer and mix evenly (the speed of the high-speed mixer is controlled at 1000r / min), then add silane coupling agent at room temperature, and then add horse To the acid anhydride graft, after mixing evenly (mixing 3min), add enhanced function talcum powder and carbon black and mix evenly;

[0061] 2) When the temperature of the mixture in the high-speed mixer reaches 40 degrees, add the defoamer and mix evenly; when the temp...

Embodiment 3

[0069] A double-wall corrugated pipe modified by using waste HDPE, the inner layer and the outer layer are mainly prepared from the following raw materials in parts by weight:

[0070]

[0071]

[0072]

[0073] Corresponding to the above-mentioned manufacturing process of using waste HDPE to modify the double-wall corrugated pipe, the process steps are as follows:

[0074] A) The production steps of the special material for the inner layer are as follows:

[0075] 1) Pour HDPE regenerated crushed material and LLDPE raw materials into a high-speed mixer and mix evenly (the speed of the high-speed mixer is controlled at 1000r / min), then add silane coupling agent at room temperature, and then add horse To the acid anhydride graft, after mixing evenly (mixing 3min), add enhanced function talcum powder and carbon black and mix evenly;

[0076] 2) When the temperature of the mixture in the high-speed mixer reaches 42 degrees, add a defoamer and mix evenly. When the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com