Modified polyolefin drpo steel plastic reinforced winding drainage and sewage pipe

A polyolefin, sewage pipe technology, applied in the direction of rigid pipes, pipes, pipes/pipe joints/fittings, etc., can solve the problems of low ring flexibility and insufficient stiffness, improve ring flexibility, meet performance requirements, and ring stiffness. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

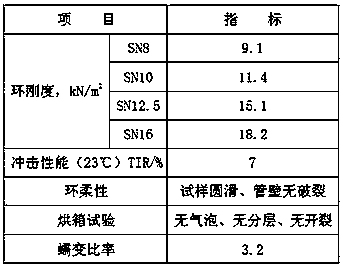

Embodiment 1

[0022] Preparation of Modified Polyolefin Elastomer BPOE

[0023] Configure raw materials by the following parts by weight:

[0024] Ethylene octene copolymer (POE): 100 parts

[0025] Styrene (St): 2 parts

[0026] Glycidyl methacrylate (GMA): 6 parts

[0027] Dicumyl peroxide (DCP): 0.1 parts;

[0028] The grafting equipment adopts twin-screw extruder to prepare modified POE by reactive extrusion process, and the process conditions are as follows:

[0029] The temperature of each section of the twin-screw extruder is (°C): 160, 170, 185, 190, 190.

[0030] Preparation of modified talcum powder

[0031] Configure raw materials by the following parts by weight:

[0032] Talcum powder 100 parts,

[0033] 1 part of silane coupling agent,

[0034] Aluminate coupling agent 0.5 part.

[0035] Preparation of modified polyolefin composites

[0036] 50 parts of polyolefin, high-density polyethylene (HDPE) for polyolefin, 10 parts of modified polyolefin elastomer BPOE, 20 par...

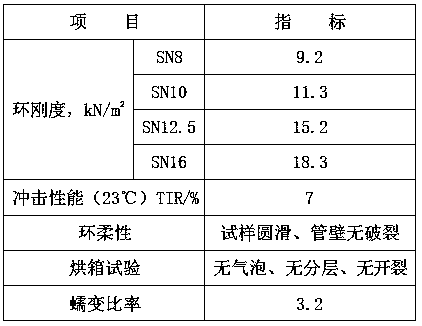

Embodiment 2

[0043] Preparation of Modified Polyolefin Elastomer BPOE

[0044] Configure raw materials by the following parts by weight:

[0045] Ethylene octene copolymer (POE): 100 parts

[0046] Styrene (St): 7 parts

[0047] Glycidyl methacrylate (GMA): 3 parts

[0048] Dicumyl peroxide (DCP): 0.4 parts;

[0049] The grafting equipment adopts twin-screw extruder to prepare modified POE by reactive extrusion process, and the process conditions are as follows:

[0050] The temperature of each section of the twin-screw extruder is (°C): 160, 170, 185, 190, 190.

[0051] Preparation of modified talcum powder

[0052] Configure raw materials by the following parts by weight:

[0053] Talcum powder 100 parts,

[0054] 3 parts of silane coupling agent,

[0055] Aluminate coupling agent 1.5 parts.

[0056] Preparation of modified polyolefin composites

[0057] 75 parts of polyolefin, random copolymerized polypropylene PPR for polyolefin, 5 parts of modified polyolefin elastomer BPOE,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com