Cooling napped fabric

A fabric and brushing technology, applied in the field of textile fabrics and fabrics, can solve the problems of no three-dimensional effect, limited application scope, and single color of the cloth surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

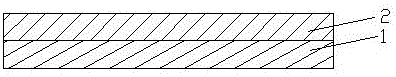

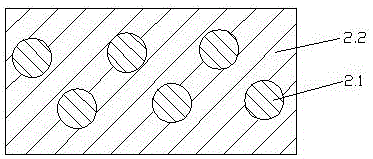

[0015] see figure 1 and figure 2 , The present invention relates to a cooling brushed fabric, comprising a fabric body 1, the surface of the fabric body 1 has a fluff layer 2, and the fluff layer 2 includes a pattern area 2.1 and a non-pattern area 2.2. The direction of the fluff in the pattern area 2.1 and the non-pattern area 2.2 is reversed by means of hot pressing, so as to highlight the three-dimensional effect of the pattern in the pattern area 2.1, which is full of fashion.

[0016] The back of the fabric body is provided with a lining fabric layer, and the lining fabric layer is a cooling fabric, which includes a plurality of cooling yarns, a plurality of non-cooling yarns, and a plurality of fabrics formed by interweaving cooling yarns and non-cooling yarns. one interweaving point, wherein each cool feeling yarn comprises a plurality of hydrophilic polyester fibers; the interweaving point comprises at least one cool feeling floating point and at least one non-cool f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com