Patents

Literature

36results about How to "Full of fashion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrating brushed fabric

InactiveCN102877198AHighlight the three-dimensional senseFull of fashionWeft knittingWarp knittingEngineeringRadiation resistance

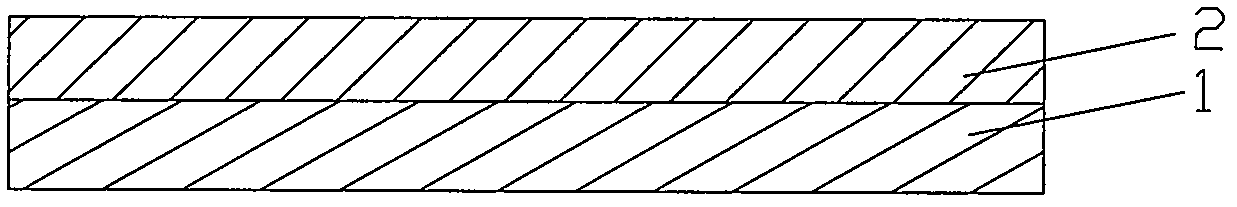

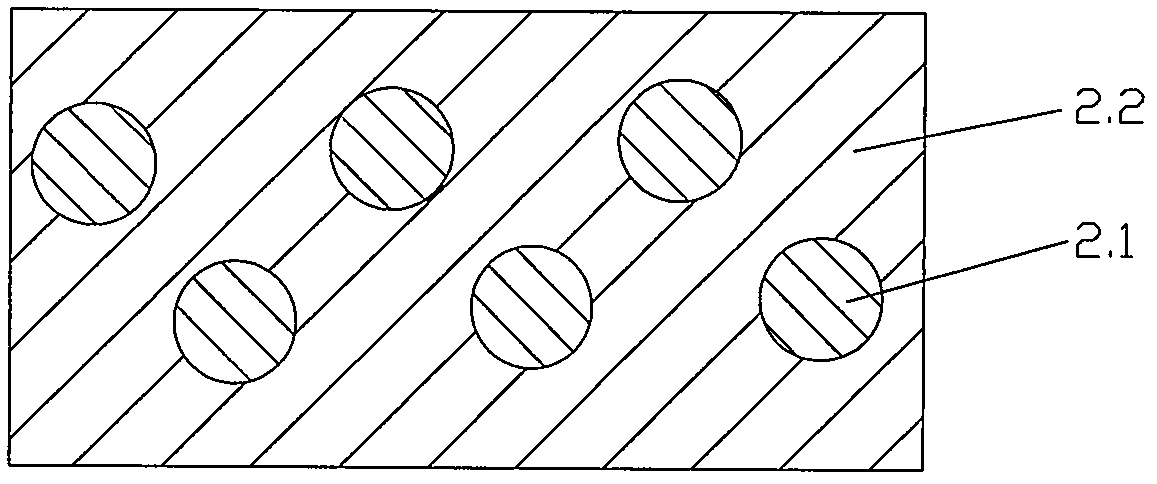

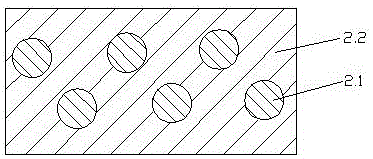

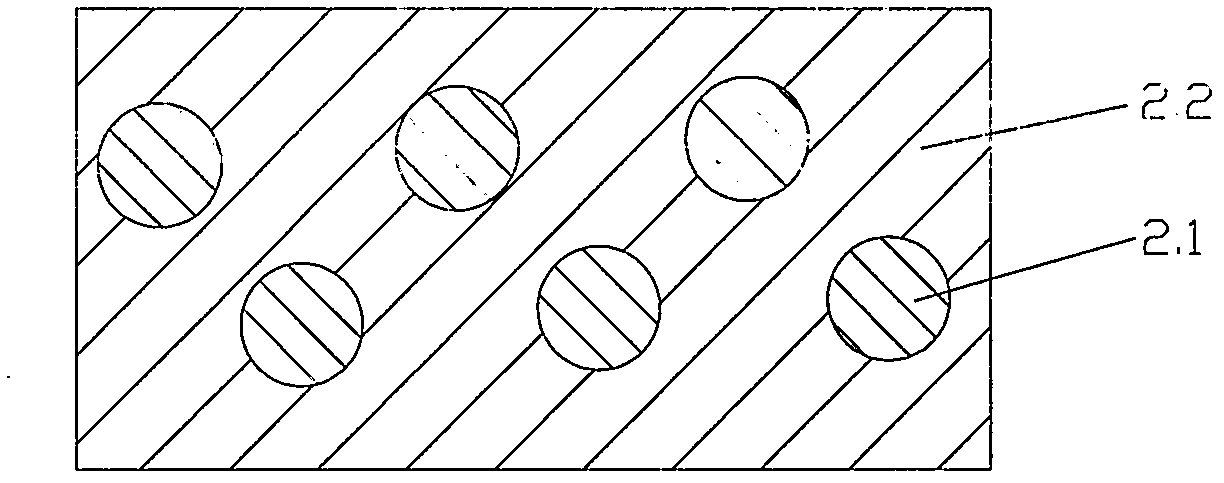

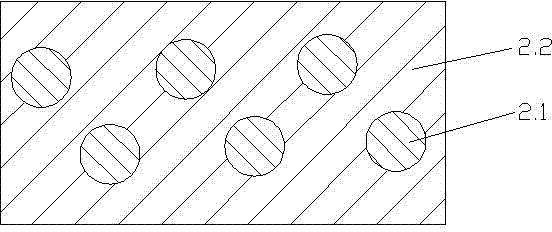

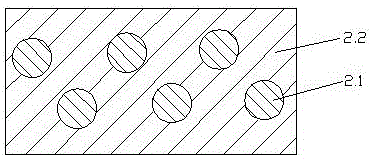

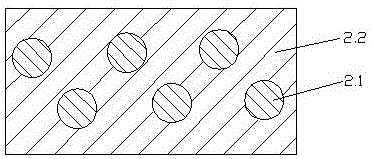

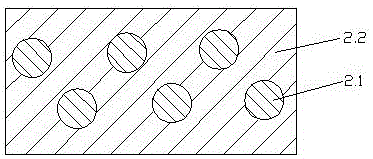

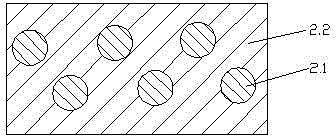

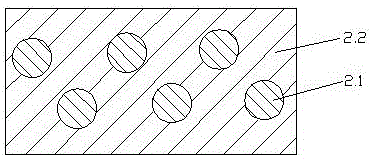

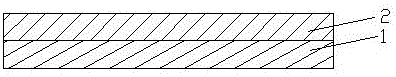

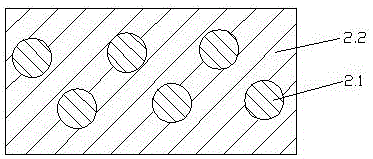

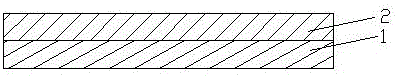

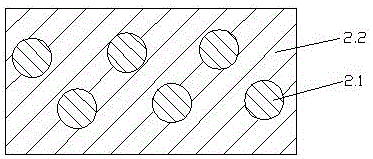

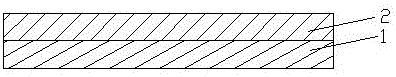

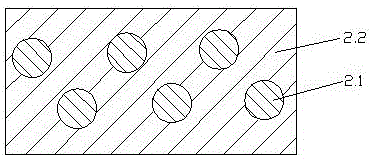

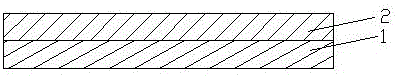

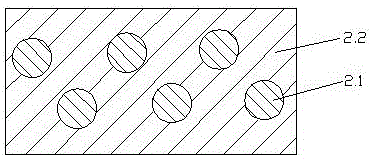

The invention relates to a hydrating brushed fabric which can be widely used for clothing, curtains, scarves, cases, toys, ornaments, bedding and the like, and belongs to the field of textile fabrics. The brushed fabric comprises a fabric main body (1); the fabric main body (1) is formed by blending aramid fibers 1313, aramid fibers 1414, and anti-static cottons. A floss layer (2) is arranged on the surface of the fabric main body (1); the floss layer (2) comprises a pattern area (2.1) and a non-pattern area (2.2); and the floss of the pattern area (2.1) and the non-pattern area (2.2) is in inverse directions. Due to the fact that the floss of the pattern area and the non-pattern area is in inverse directions, the stereoscopic impression of the patterns in the pattern area is prompted, and the fabric is enriched in flavor of fashion. Meanwhile, the fabric provided by the invention not only has effects of hydrating and ventilating but also has excellent radiation resistance property, so that the comfort and the security of the use of the fabric are improved.

Owner:孙建良

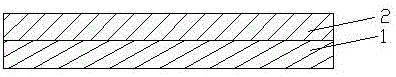

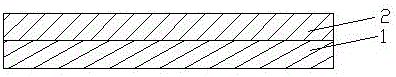

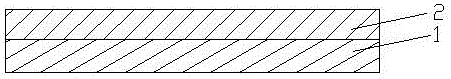

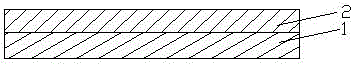

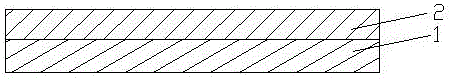

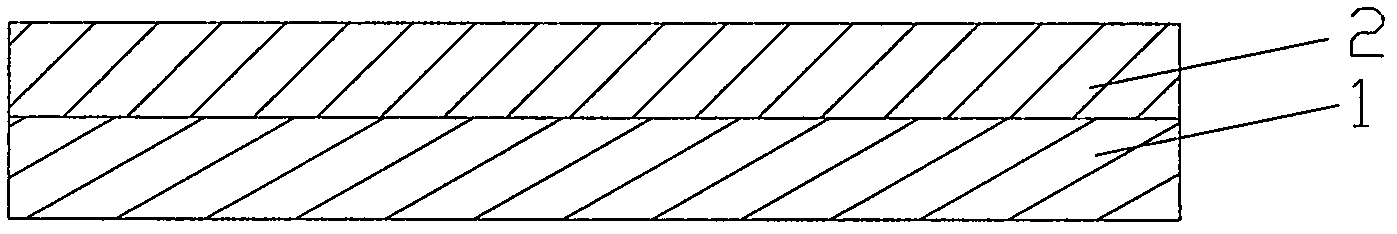

Composite fabric of wrinkle fabric and knitted fabric

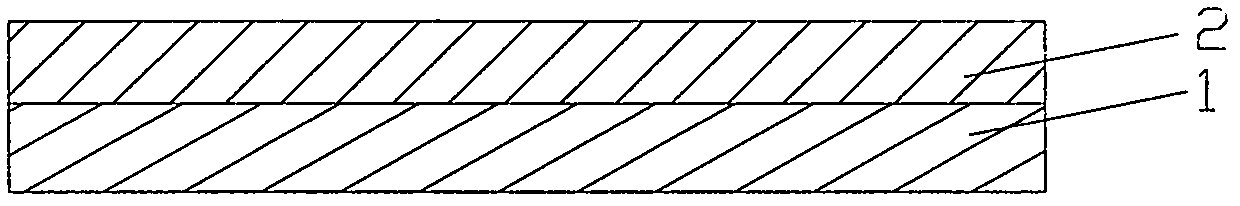

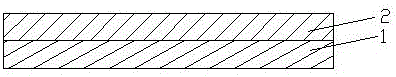

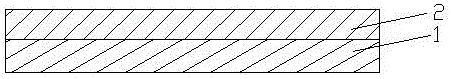

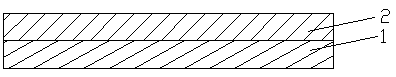

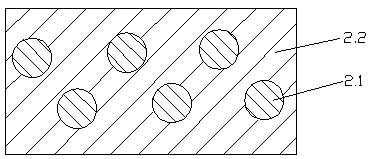

The invention relates to a composite fabric of a wrinkle fabric and a knitted fabric, which is widely applied to production of high-end women's dresses and belongs to the field of textile fabrics. The composite fabric of the wrinkle fabric and the knitted fabric comprises a knitted fabric body (1) and is characterized in that the wrinkle fabric (2) is fixed above the knitted fabric body (1). The composite fabric of the wrinkle fabric and the knitted fabric has the respective advantages of the wrinkle fabric and the knitted fabric, and clothes made of the composite fabric are light and thin in quality, warm-keeping, comfortable, attractive, three-dimensional and full of fashionable breath.

Owner:奚晓莉

Brushed fabric with unit coils mutually interlooped

InactiveCN106048867ADense metal networkGood flexibilityWeft knittingWarp knittingBiomedical engineeringStainless steel fiber

Owner:JIANGYIN DONGFA GARMENT MAKING

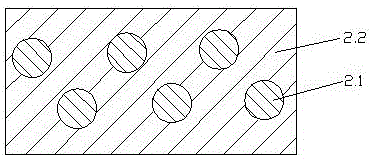

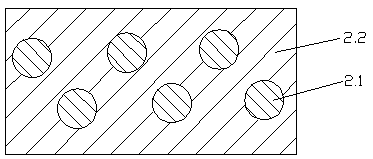

Brushed fabric

InactiveCN102877197AHighlight the three-dimensional senseFull of fashionWeft knittingWarp knittingYarnEngineering

The invention relates to a brushed fabric, and belongs to the field of textile fabrics. The brushed fabric comprises a fabric main body (1); the fabric main body (1) is formed by wraps and wefts which are interwoven with each other in a raise-and-fall form; the fineness of the wraps and the wefts are 15D; the summation of the number of the wraps and the wefts in each square inch of the fabric main body (1) is 520; a floss layer (2) is arranged on the surface of the fabric main body (1); the floss layer (2) comprises a pattern area (2.1) and a non-pattern area (2.2); and the floss of the pattern area (2.1) and the non-pattern area (2.2) is in inverse directions. Due to the fact that the floss of the pattern area and the non-pattern area is in inverse directions, the stereoscopic impression of the patterns in the pattern area is prompted, and further, the fabric is enriched in flavor of fashion. The fabric processed by the invention is high in density, light in weight, facile in hand feeling and smooth; the product cloth made of the fabric has the advantages of nature, comfort, lightness and fashion.

Owner:杨洁

Radiation-preventive napped fabric

InactiveCN102899790AHighlight the three-dimensional senseFull of fashionWeft knittingLayered productsEngineeringHeat energy

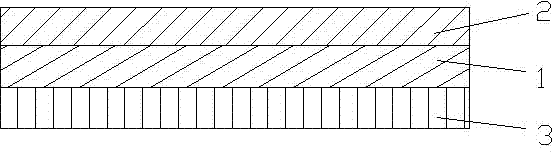

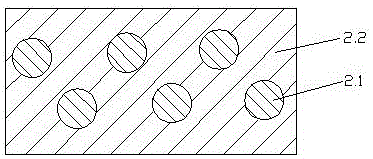

The invention relates to a radiation-preventive napped fabric, and belongs to the field of textile fabrics. The radiation-preventive napped fabric can be widely applied to clothing, curtains, scarf, bags, toys, ornaments, beddings and the like. The napped fabric comprises a fabric body (1), a nap layer (2) is arranged on the front surface of the fabric body (1) and comprises pattern regions (2.1) and a non-pattern region (2.2), directions of naps of the pattern regions (2.1) are opposite to those of naps of the non-pattern region (2.2), and a wave absorbing layer (3) is closely compounded on the back surface of the fabric body (1). The stereoscopic impression of patterns in the pattern regions is highlighted owing to the opposite directions of the naps of the pattern regions and the naps of the non-pattern region of the napped fabric, and the radiation-preventive napped fabric is fashionable. Besides, the radiation-preventive napped fabric has the advantages that indoor radiation waves can be effectively absorbed and converted into heat energy, the shortcoming that radiation waves are absorbed by the skin, which is exposed to the outside, of a user after the radiation waves are reflected by existing radiation-proof cloth is overcome, and the radiation-preventive napped fabric is favorable for preventing radiation.

Owner:江阴市振新毛纺有限公司

Loop-raised fabric capable of permanently emitting large quantity of anions

The invention relates to a brushed fabric which permanently emits a large amount of negative ions. It includes a fabric body (1); the surface of the fabric body (1) has a fluff layer (2), the fluff layer (2) includes a pattern area (2.1) and a non-pattern area (2.2), and the pattern area (2.1) and the non-pattern area Region (2.2) has villi in the opposite direction. The back of the fabric body is provided with a lining fabric layer, and the lining fabric layer is a kind of negative ion fabric, which includes general yarns, elastic yarns and negative ion yarns interwoven through double-sided weaving; the general yarn weaving 2% of the elastic yarn replaces part of the common yarn in the weaving arrangement, and the negative ion yarn is woven on the inner surface and the component content is less than 48%. The pile direction of the pattern area of the brushed fabric is opposite to that of the non-pattern area, which highlights the three-dimensionality of the pattern in the pattern area and is full of fashion. The present invention permanently emits a large amount of negative ions.

Owner:JIANGYIN CHUNZHILAN SPECIAL YARN

Nap fabric capable of improving optical rotation conductivity

InactiveCN106087494AFull of fashionImprove optical conductivityTextile decorationOpen work fabricsEngineeringNap

The invention relates to a nap fabric capable of improving optical rotation conductivity. The nap fabric comprises a fabric body (1). A nap layer (2) is arranged on the surface of the fabric body (1) and comprises a pattern region (2.1) and a non-pattern region (2.2), and the direction of nap on the pattern region (2.1) is opposite to that of nap on the non-pattern region (2.2). A lining fabric layer is arranged on the back side of the fabric body, and the lining fabric layer is luminous fabric and comprises a light transmitting unit, at least one light emitting unit combined with the light transmitting unit and an electric power unit electrically connected with the light emitting units. The light transmitting unit comprises a plurality of complex fibers, and each complex fiber comprises a sheath part. Due to the fact that the direction of the nap on the pattern region is opposite to that of the nap on the non-pattern region of the nap fabric, the third dimension of a pattern in the pattern region is made prominent, and a stylish atmosphere is created; the nap fabric improves optical rotation conductivity.

Owner:JIANGYIN DUJUAN BEADED

Napping fabric with soft handfeel and good drapability

The invention relates to a napping fabric with the soft handfeel and the good drapability. The napping fabric comprises a fabric body (1); a fluff layer (2) is arranged on the surface of the fabric body (1) and comprises a pattern area (2.1) and a non-pattern area (2.2), and the fluff direction of the pattern area (2.1) is opposite to that of the non-pattern area (2.2). A lining fabric layer is arranged on the reverse side of the fabric body and comprises two mesh surface layers distributed in parallel and an elastic material layer arranged between the mesh surface layers, wherein multiple through holes are distributed on each mesh surface layer. Through the opposite fluff directions of the pattern area and the non-pattern area of the napping fabric, stereoscopic impression of patterns in the pattern area is highlighted, and the fashionable breath is achieved. The napping fabric is soft in handfeel and good in drapability.

Owner:JIANGYIN XINJIAMEI GARMENTS

All-brushed fabric printed with identification units

InactiveCN106273706AAvoid misprintHighlight the three-dimensional senseLayered productsInformation layerEngineering

The invention relates to all-brushed fabric printed with identification units. The all-brushed fabric comprises a fabric body (1), wherein a fluff layer (2) is arranged on the surface of the fabric body (1), the fluff layer (2) comprises pattern regions (2.1) and a non-pattern region (2.2), and the fluff direction of the pattern regions (2.1) is opposite to the fluff direction of the non-pattern region (2.2); a lining fabric layer is arranged on the back of the fabric body, is porous fabric, comprises a base material made of the porous fabric, and also comprises a bottom layer and an information layer; and the bottom layer is directly formed on the base material, and the information layer is placed on the bottom layer. The fluff direction of the pattern regions is opposite to the fluff direction of the non-pattern region of the brushed fabric, so that the stereoscopic impression of patterns in the pattern regions is highlighted, and the all-brushed fabric is full of fashionable breath. The identification units of the all-brushed fabric disclosed by the invention are completely printed.

Owner:JIANGYIN ZHONGMA PACKING MATERIAL

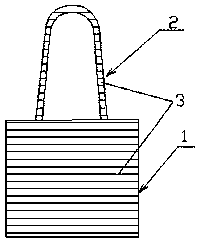

Handbag with bead strings

The invention relates to a handbag with beads, which is widely used in women's satchels, handbags, coin purses and the like.

Owner:刘邦佐

Micro-fluffed and conductive compound fabric of folded fabric and knitted fabric

InactiveCN106183057AThin and lightFull of fashionSynthetic resin layered productsClothingsEngineeringAmmonium peroxydisulfate

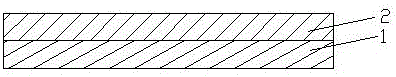

The invention relates to a micro-fluffed and conductive compound fabric of a folded fabric and a knitted fabric. The compound fabric comprises a knitted fabric body (1), and the folded fabric (2) is fixed on the knitted fabric body; a lining fabric layer is arranged on the reverse side of the knitted fabric body, and the lining fabric layer is a micro-fluffed and conductive fabric and comprises a fabric into which a conductive polyaniline polymer provided by in-situ chemical polymerization of phenylamine and an ammonium peroxydisulfate oxidizing agent in an acid medium is infiltrated. The compound fabric of the folded fabric and the knitted fabric achieves the advantages of the folded fabric and the knitted fabric, and a garment made from the compound fabric is light and thin, capable of keeping warm, comfortable and attractive in appearance and has stereoscopic impression. The compound fabric is micro-fluffed and conductive.

Owner:JIANGYIN BEIYE TEXTILE

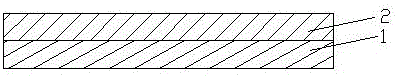

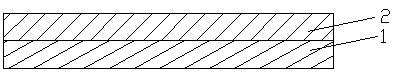

Brushed fabric

InactiveCN102615869AHighlight the three-dimensional senseFull of fashionLayered productsThree-dimensional effectsPattern perceptionEngineering

The invention relates to a brushed fabric, which can be widely applied to clothes, curtains, scarves, cases, toys, ornaments, bedclothes and the like and belongs to the textile fabric field. The brushed fabric comprises a brushed fabric body (1), and the brushed fabric is characterized in that the surface of the brushed fabric body (1) is provided with a fluff layer (2), the fluff layer (2) comprises a pattern area (2.1) and a non-pattern area (2.2), and the fluff direction of the pattern area (2.1) is opposite to that of the non-pattern area (2.2). The fluff direction oppositeness of the pattern area to the non-pattern area of the brushed fabric enhances the stereo perception of patterns in the pattern area, so the brushed fabric is fashionable.

Owner:奚晓莉

Luminous wrinkle and knitted composite fabric

The invention relates to a luminous wrinkle and knitted composite fabric. The fabric includes a knitted fabric body (1), a wrinkle fabric (2) fixed on the upper surface thereof. A lining fabric layer is arranged on the back of the knitted fabric body (1). The lining fabric layer is a luminous fabric and includes at least one passive luminous yarn and at least one positive luminous yarn, which are interwoven with each other; or the passive luminous yarn is wrapped by the positive luminous yarn. The composite fabric has the advantages of both the knitted fabric and the wrinkle fabric. A clothes prepared from the fabric is light in weight, is warm-keeping, comfortable and beautiful and also has a stereo sense. The composite fabric is luminous.

Owner:JIANGYIN CHUNLAN TEXTILE

Napping fabric capable of preventing evaporation heat loss

InactiveCN106183112AReduce discharge efficiencyImprove insulation effectSynthetic resin layered productsPolyesterEvaporation

The invention relates to a brushed fabric for preventing evaporation heat loss. It includes a fabric body (1); the surface of the fabric body (1) has a fluff layer (2), the fluff layer (2) includes a pattern area (2.1) and a non-pattern area (2.2), and the pattern area (2.1) and the non-pattern area Region (2.2) has villi in the opposite direction. The back of the fabric body is provided with a lining fabric layer. The lining fabric layer is a composite fabric consisting of a lining, a barrier layer and a fabric layer that is not easily wetted by water. The barrier layer is made of polyethylene, nylon, polyester, Made of either urethane or polytetrafluoroethylene. The pile direction of the pattern area of the brushed fabric is opposite to that of the non-pattern area, which highlights the three-dimensionality of the pattern in the pattern area and is full of fashion. The present invention prevents evaporation heat loss.

Owner:JIANGYIN JIAYI GIFT

Cooling napped fabric

InactiveCN106183055AHighlight the three-dimensional senseFull of fashionOrnamental textile articlesSynthetic resin layered productsPolyesterYarn

The invention relates to a cooling napped fabric. The cooling napped fabric comprises a fabric body (1), the surface of the fabric body (1) is provided with a napped layer which comprises a pattern area (2.1) and a non-patterned area (2.2), and the pattern area (2.1) and the non-patterned area (2.2) are opposite in nap direction. The back surface of the fabric body is provided with a lining fabric layer, and the lining fabric layer is a cooling fabric and comprises a plurality of cooling yarns, a plurality of non-cooling yarns and a plurality of interlacing points formed by interlacing of the cooling yarns and the non-cooling yarns. Each cooling yarn comprises a plurality of hydrophilic polyester fibers, and the interlacing points include at least one cooling floating point and at least one non-cooling floating point. Due to opposite nap direction of the pattern area and the non-patterned area of the napped fabric, stereoscopic property of patterns in the pattern area is prominent, and high stylishness is realized. In addition, the cooling napped fabric has a cooling function.

Owner:JIANGYIN HANXIN TEXTILE

Brushed fabric capable of enhancing siphon action on inner sweat

InactiveCN106183255AIncreased total surface areaImprove water absorptionPattern makingSynthetic resin layered productsSiphonYarn

The invention relates to a brushed fabric with a siphon effect on the inner sweat. It includes a fabric body (1); the surface of the fabric body (1) has a fluff layer (2), the fluff layer (2) includes a pattern area (2.1) and a non-pattern area (2.2), and the pattern area (2.1) and the non-pattern area Region (2.2) has villi in the opposite direction. The back of the fabric body is provided with a lining fabric layer, and the lining fabric layer is a double-layer fabric formed by interweaving an inner layer and an outer layer, and the inner layer is woven with polypropylene fibers having water-repellent properties; The outer layer is woven with a special-shaped cross-section yarn with hydrophilic physical properties. The pile direction of the pattern area of the brushed fabric is opposite to that of the non-pattern area, which highlights the three-dimensionality of the pattern in the pattern area and is full of fashion. The present invention multiplies the siphon effect on inner sweat.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Wrinkled and knitted composite fabric with wider applicable range of nano-silver health fiber

The invention relates to a wrinkled and knitted composite fabric which expands the application range of silver rice healthy fiber. It includes a knitted fabric body (1), and a folded fabric (2) is fixed on the upper surface of the knitted fabric body. The back of the knitted fabric body is provided with a lining fabric layer, and the lining fabric layer is a kind of warp knitted fabric. The warp knitted fabric is composed of yarns and filaments wrapped around the yarns, and the wrapping is spiral shape, the yarn includes a core yarn, the core yarn is silver rice healthy fiber or silver rice healthy fiber and other fibers composite yarn, other fibers are cotton, hemp, wool, polyester, nylon or spandex filament is polyester or nylon . The composite fabric of pleats and knitting takes advantage of the respective advantages of pleated fabrics and knitted fabrics, and the clothes made are light and thin, warm, comfortable and beautiful, and have a three-dimensional effect. The invention expands the application range of the silver rice healthy fiber.

Owner:JIANGYIN DUJUAN BEADED

Pleated and knitted complex fabric capable of enhancing siphon action on inner sweat

InactiveCN106183108AThin and lightFull of fashionSynthetic resin layered productsMulti-ply fabricsYarnBiomedical engineering

The invention relates to a pleated and knitted complex fabric capable of enhancing siphon action on inner sweat. The complex fabric comprises a knitted fabric body (1) on which a pleated fabric (2) is fixed. A lining fabric layer is arranged on the back of the knitted fabric body, and is a double-layer fabric formed by interweaving an inner layer and an outer layer, and the inner layer is woven with polypropylene fibers having a hydrophobic property; the outer layer is woven with modified cross-section yarns having a hydrophilic property. The pleated and knitted composite fabric has the respective advantages of the pleated fabric and the knitted fabric,and the made garment is light in weight, and is warm, comfortable, beautiful and three-dimensional.The siphon action on inner sweat is enhanced by the pleated and knitted complex fabric provided by the invention.

Owner:JIANGYIN GUORUN TEXTILE RAW MATERIALS SALES

Decorative and practical napping fabric

InactiveCN106183109ADecorativePracticalLayered productsWoven fabricsEngineeringStructural engineering

The invention relates to a decorative and practical napping fabric, comprising a fabric body (1); the surface of the fabric body (1) is provided with a nap layer (2) that includes a pattern area (2.1) and a non-pattern area (2.2), and the pattern area (2.1) and the non-pattern area (2.2) are opposite in nap direction; the back of the fabric body is provided with a lining fabric layer that is Kesi fabric, and the Kesi fabric includes a plurality of warps arranged in parallel and a plurality of wefts continuously and / or non-continuously arranged, a plurality of locally naturally hollowed patterns interwoven of the wefts and the warps are distributed on the surface of the fabric. The pattern area and non-pattern area of the napping fabric highlight the pattern stereoscopicity in the pattern area in the opposite nap directions, and the fabric is imparted fashion; the fabric is decorative and practical.

Owner:JIANGYIN CHUNLAN TEXTILE

Pleating and knitting compound fabric with soft hand feeling and good draping property

The invention relates to a pleating and knitting compound fabric with a soft hand feeling and a good draping property. The pleating and knitting compound fabric comprises a knitted fabric body (1), wherein a pleated fabric (2) is fixed on the knitted fabric body; a lining fabric layer is arranged on the back side of the knitted fabric body and comprises a surface layer and an inner layer; the surface layer and the inner layer are interweaved by warp yarns and weft yarns to form a whole body; a bamboo charcoal layer is additionally arranged on the surface of the inner layer. The pleating and knitting compound fabric plays respective advantages of the pleated fabric and the knitted fabric; produced clothes are light in weight, can keep warm, are comfortable and attractive, and have a stereoscopic impression. The pleating and knitting compound fabric disclosed by the invention has the soft hand feeling and the good draping property.

Owner:JIANGYIN YIFAN IND & TRADE

Crease and knitted composite fabric with good tear resistance

InactiveCN106218016AThin and lightFull of fashionLayered productsClothingsEngineeringTear resistance

The invention relates to a crease and knitted composite fabric with the good tear resistance. The composite fabric comprises a knitted fabric body (1). A crease fabric (2) is fixed to the knitted fabric body. A liner fabric layer is arranged on the back face of the knitted fabric body. The liner fabric layer is a composite fabric and includes a first weaving layer and a first film layer. The first weaving layer is provided with a first surface, a second surface and a plurality holes. The holes are distributed in the first weaving layer and communicated with the first surface and the second surface. The crease and knitted composite fabric has the advantages of a crease fabric and a knitted fabric, and an obtained garment is light and thin in mass, warm, comfortable and attractive and has third dimension. The composite fabric is good in tear resistance.

Owner:JIANGYIN CHENGXIN SPECIAL PRINTING

Wrinkled and knitted laminated fabric capable of cooling

The invention relates to a composite fabric of cooling folds and knitting. It includes a knitted fabric body (1), and a folded fabric (2) is fixed on the upper surface of the knitted fabric body. The back of the knitted fabric body is provided with a lining fabric layer, and the lining fabric layer is a cooling fabric, which includes a plurality of cooling yarns, a plurality of non-cooling yarns, and a fabric formed by interweaving cooling yarns and non-cooling yarns. A plurality of interweaving points, wherein each cooling yarn includes a plurality of hydrophilic polyester fibers; the interweaving points include at least one cooling sensation floating point and at least one non-cooling sensation floating point. The composite fabric of pleats and knitting takes advantage of the respective advantages of pleated fabrics and knitted fabrics, and the clothes made are light and thin, warm, comfortable and beautiful, and have a three-dimensional effect. The present invention cools down.

Owner:JIANGYIN QUANSHUN TEXTILE CO LTD

High-supporting-performance pleated and knitted composite fabric

The invention relates to a high support pleated and knitted composite fabric. It includes a knitted fabric body (1), and a folded fabric (2) is fixed on the upper surface of the knitted fabric body. The back of the knitted fabric body is provided with a lining fabric layer, the lining fabric layer is a fabric improvement structure, including an upper fabric layer, a middle fabric layer and a lower fabric layer stacked on each other in sequence, wherein the middle fabric The layers are corrugated, and the upper or lower fabric layer is composed of 100% elastane. The composite fabric of pleats and knitting takes advantage of the respective advantages of pleated fabrics and knitted fabrics, and the clothes made are light and thin, warm, comfortable and beautiful, and have a three-dimensional effect. The invention is highly supportive.

Owner:JIANGYIN HARVEST KNITTING & GARMENTS

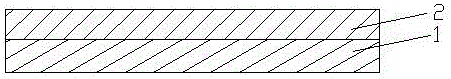

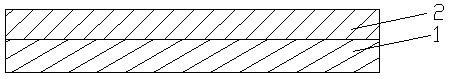

Composite fabric of wrinkle fabric and knitted fabric

The invention relates to a composite fabric of a wrinkle fabric and a knitted fabric, which is widely applied to production of high-end female dresses and belongs to the field of textile fabric. The composite fabric of the wrinkle fabric and the knitted fabric comprises a knitted fabric body (1) and is characterized in that the wrinkle fabric (2) is fixed above the knitted fabric body (1). The composite fabric of the wrinkle fabric and the knitted fabric has the respective advantages of the wrinkle fabric and the knitted fabric, and clothes made of the composite fabric are light and thin in quality, warm-keeping, comfortable, attractive, three-dimensional and full of fashionable breath.

Owner:杨洁

Wrinkle and knitting composite fabric with relatively high aesthetic feeling

InactiveCN107650446AThin and lightFull of fashionLayered productsProtective garmentEngineeringTextile

The invention relates to a folded and knitted composite fabric with high aesthetic feeling. It includes a knitted fabric body (1), and a folded fabric (2) is fixed on the upper surface of the knitted fabric body. The back of the knitted fabric body is provided with a lining fabric layer, the lining fabric layer is a kind of spider web fabric, including an inner ring, ribs, and loops, the ribs are three or more, one end of which is evenly fixed on the On the inner ring, the other ends of the ribs are evenly distributed radially outside the inner ring, and the loops are spirally wound with the ribs sequentially from the inner ring outward. The composite fabric of pleats and knitting takes advantage of the advantages of both pleated fabrics and knitted fabrics, and the garments are light and thin, warm, comfortable and beautiful, and have a three-dimensional effect. The present invention has higher aesthetic feeling.

Owner:JIANGYIN JIANGZHOU PRINTING & DYEING CO LTD

Luminescent brushed fabric

InactiveCN107650450AHighlight the three-dimensional senseFull of fashionLayered productsYarnEngineering

The invention relates to a luminescent brushed fabric. It includes a fabric body (1); the surface of the fabric body (1) has a fluff layer (2), the fluff layer (2) includes a pattern area (2.1) and a non-pattern area (2.2), and the pattern area (2.1) and the non-pattern area Region (2.2) has villi in the opposite direction. A lining fabric layer is provided on the back of the fabric body, and the lining fabric layer is a luminescent fabric, including at least one passive luminescent yarn and at least one active luminescent yarn. Wherein, the active luminescent yarn and the passive luminescent yarn are interwoven, or the passive luminescent yarn is surrounded by the active luminescent yarn. The pile direction of the pattern area of the brushed fabric is opposite to that of the non-pattern area, which highlights the three-dimensionality of the pattern in the pattern area and is full of fashion. The invention shines.

Owner:JIANGYIN HAOZHOU TEXTILE CO LTD

High-support loop-raised fabric

Owner:JIANGYIN YIFAN IND & TRADE

Spot-jacquard loop-raised fabric

InactiveCN107663689AEnhance the sense of widthSuitable for different needsLayered productsWoven fabricsYarnEngineering

The invention relates to a mottled jacquard brushed fabric. It includes a fabric body (1); the surface of the fabric body (1) has a fluff layer (2), the fluff layer (2) includes a pattern area (2.1) and a non-pattern area (2.2), and the pattern area (2.1) and the non-pattern area Region (2.2) has villi in the opposite direction. The back of the fabric body is provided with a lining fabric layer, and the lining fabric layer is a speckled jacquard fabric, which is a double-sided jacquard fabric. The front side is uniformly and independently distributed with convex points, and the convex points are made of the first yarn jacquard Formed on the base fabric, the reverse side is vertical stripes formed on the reverse side of the base fabric by the second yarn jacquard, and the adjacent stripes are parallel. The pile direction of the pattern area of the brushed fabric is opposite to that of the non-pattern area, which highlights the three-dimensional effect of the pattern in the pattern area and is full of fashion. The speckled jacquard of the present invention.

Owner:黄磊

Napping fabric with reasonable structure and good application performance

InactiveCN106113691AHighlight the three-dimensional senseFull of fashionCellulosic plastic layered productsHeating/cooling textile fabricsEngineeringViscose fiber

The invention relates to a napping fabric with a reasonable structure and good application performance. The napping fabric comprises a fabric body (1), wherein the surface of the fabric body (1) is provided with a fluff layer (2), the fluff layer (2) comprises a pattern zone (2.1) and a non-pattern zone (2.2), and the fluff direction of the pattern zone (2.1) is opposite to the fluff direction of the non-pattern zone (2.2); and the back surface of the fabric body is provided with a liner fabric layer, the liner fabric layer is formed by weaving warp yarns and weft yarns, the warp yarns adopt casein fibers, the weft yarns adopt viscose fibers, the diameter of the casein fibers is 18.62 micrometers, the fineness of the casein fibers is 252dtex, the diameter of the viscose fibers is 8.29 micrometers, the fineness of the viscose fibers is 198dtex, the warp density is 25.9 fibers per centimeter, the weft density is 16.3 fibers per centimeter, and a reinforced cross-grain structure is adopted. The opposite fluff direction of the pattern zone and non-pattern zone of the napping fabric highlights the stereoscopic impression of patterns in the pattern zone, and the napping fabric is fashionable. The napping fabric is reasonable in structure and good in application performance.

Owner:JIANGYIN YUEDA DYEING & PRINTING

Napping fabric with good rigidity and hardness

The invention relates to a napping fabric with good rigidity and hardness. The napping fabric comprises a fabric body (1), wherein the surface of the fabric body (1) is provided with a napping layer (2); the napping layer (2) comprises a pattern area (2.1) and a non-pattern area (2.2); and the napping direction of the pattern area (2.1) is opposite to that of the non-pattern area (2.2). A lining fabric layer is arranged at the back of the fabric body; the lining fabric layer is made of braided fabric; and the braided fabric can comprise a plurality of warps and at least one weft coupled with the warps. The braided fabric further can comprise a plurality of jointed fibers. The jointed fibers can be positioned to be parallel to the warps and / or parallel to the wefts. Moreover, the jointed fibers can be formed by a material with a melting point temperature which is lower than that of a material for forming the warps and the wefts of the braided fabric. The opposite napping directions of the pattern area and the non-pattern area of the napping fabric highlight the stereoscopic impression of patterns in the pattern area, and the napping fabric is full of fashionable breath. The napping fabric is good in rigidity and hardness.

Owner:JIANGYIN BETTER TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com