Deck passage frame connecting structure

A technology for connecting structures and passages, which is applied to ship components, ships, dry docks, etc., can solve the problems of low production utilization rate of operators, inconsistent erection standards, and irregular use of passage materials, etc., to shorten the construction and disassembly The effect of less time and labor, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

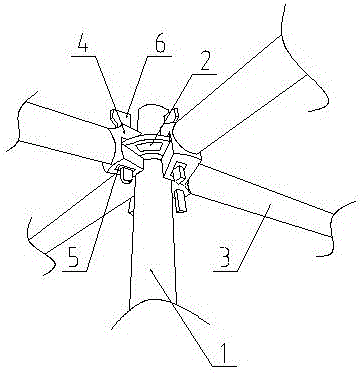

[0016] Such as figure 1 As shown, a deck channel frame connection structure in this embodiment includes a vertical rod 1, a fixed ring 2 is arranged on the upper part of the vertical rod 1, and four cross bars 3 are uniformly arranged around the fixed ring 2, so that The inner end of the cross bar 3 is provided with a chuck 4, the chuck 4 is clamped on the fixed ring 2, the chuck 4 is provided with a fixed jack 5, and the fixed jack 5 is inserted with a latch 6. The clip 4 of the cross bar 3 is fixedly connected to the fixing ring 2 through the bolt 6 .

[0017] In addition to the above-mentioned embodiments, the present invention also includes other implementations, and any technical solution formed by equivalent transformation or equivalent replacement shall fall within the protection scope of the claims of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com