Deck walkway rack building method

A channel and deck technology, applied in the field of deck channel frame construction, can solve the problems of low production utilization rate of operators, inconsistent erection standards, irregular use of channel materials, etc., so as to shorten the construction and dismantling time and labor. Less, easy to dismantle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

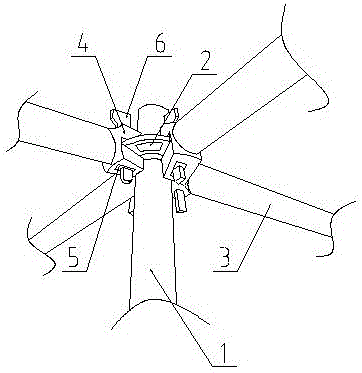

[0018] Such as figure 1 As shown, a method for erecting a deck channel frame in this embodiment includes the following steps:

[0019] Make a batch of vertical poles and horizontal poles uniformly, among which the vertical poles are 2.1 meters and the horizontal poles are 1.1 meters;

[0020] Arrange the vertical poles in multiple rows parallel to the left and right. A fixed ring is welded on the upper part of each vertical pole. The fixed rings of two adjacent vertical poles (including left and right and front and rear) are connected by a cross bar. The cross bar Both ends are provided with clips, and the clips are placed on the fixed ring, and a fixed socket is opened on the clip, and a pin is inserted in the fixed socket, and the clip of the cross bar is connected with the plug The retaining ring secures the connection.

[0021] In addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com