Patents

Literature

49results about How to "Easy to build and disassemble" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for increasing horizontal cross braces and improving and determining bearing capacity of support frame

ActiveCN102182300AImprove bearing capacitySimple structureScaffold accessoriesSection planeBearing capacity

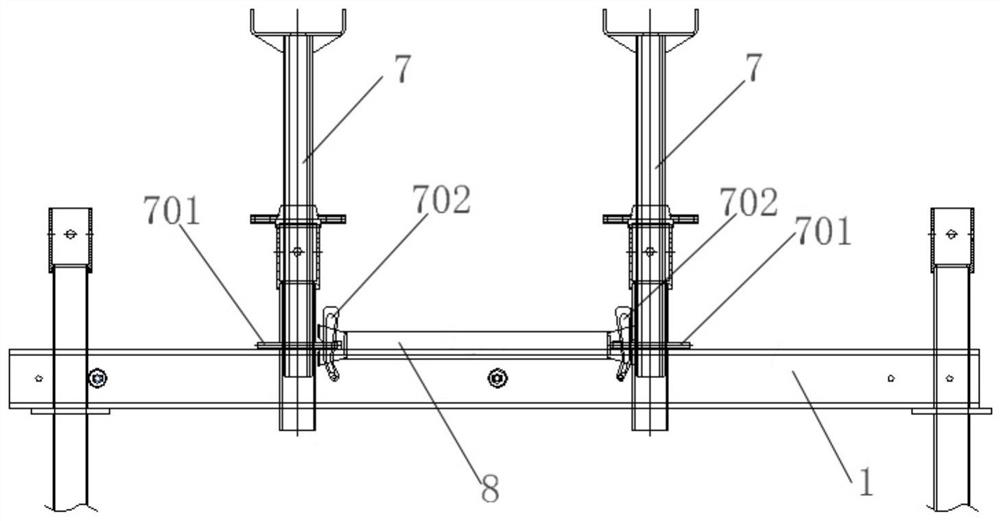

The invention relates to a method for increasing horizontal cross braces and improving and determining the bearing capacity of a support frame. The support frame comprises 10 strides in the longitudinal direction and 6 strides in the transverse direction, and is loaded in a range of 5 strides * 5 strides; 3 strides are arranged on one side in the longitudinal direction outside a loading region, and 2 strides are arranged on the other side; 1 stride is arranged on one side in the transverse direction outside the loading region, and no strides are arranged on the other side; the height of the frame is 8.2m, the step distance of vertical rods is 1.5m, the longitudinal spacing interval of the vertical rods is 0.9m, and the transverse spacing interval of the vertical rods is 0.9m; vertical cross braces are arranged on the peripheral vertical section or the vertical surface in the range of the loading region at the intervals of four rows of the vertical rods and buckled through bucklers in the positions of being jointed with the vertical rods or horizontal rods; the vertical rods, the horizontal rods and the cross braces of the support frame adopt phi 48*3.2 steel pipes; and an adjustable bracket is used for jacking the double phi 48*3.2 steel pipes at the upper part of a support for being used as a main beam for supporting load, the bottom part of the adjustable bracket is inserted into the vertical rods of the support for fixing, the distance from the upper surface of the adjustable bracket to the upper skin of a topmost transverse pipe of the support is 0.5m, and the adjustable bracket extends out of the vertical rods by 0.3m. The bearing capacity of the structure is improved, and the application prospects are broad.

Owner:杭州二建建设集团有限公司

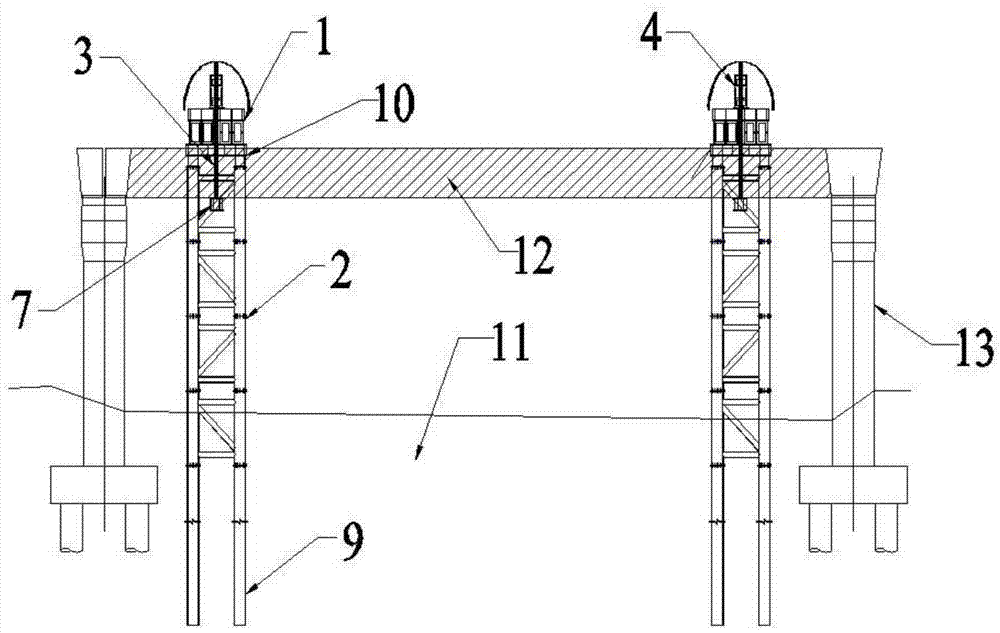

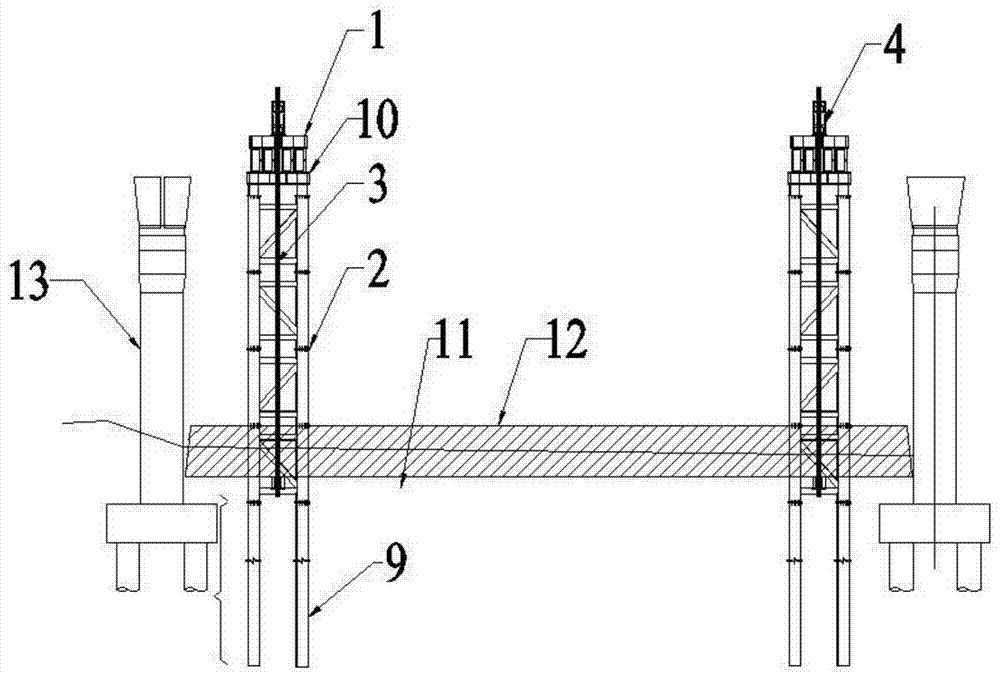

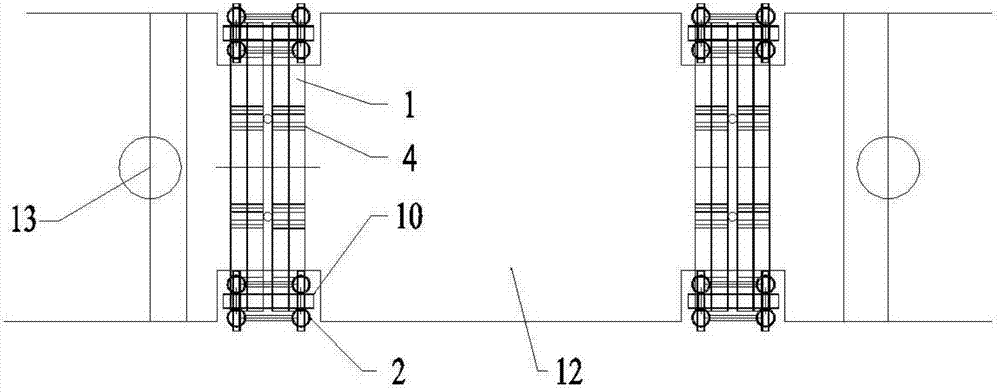

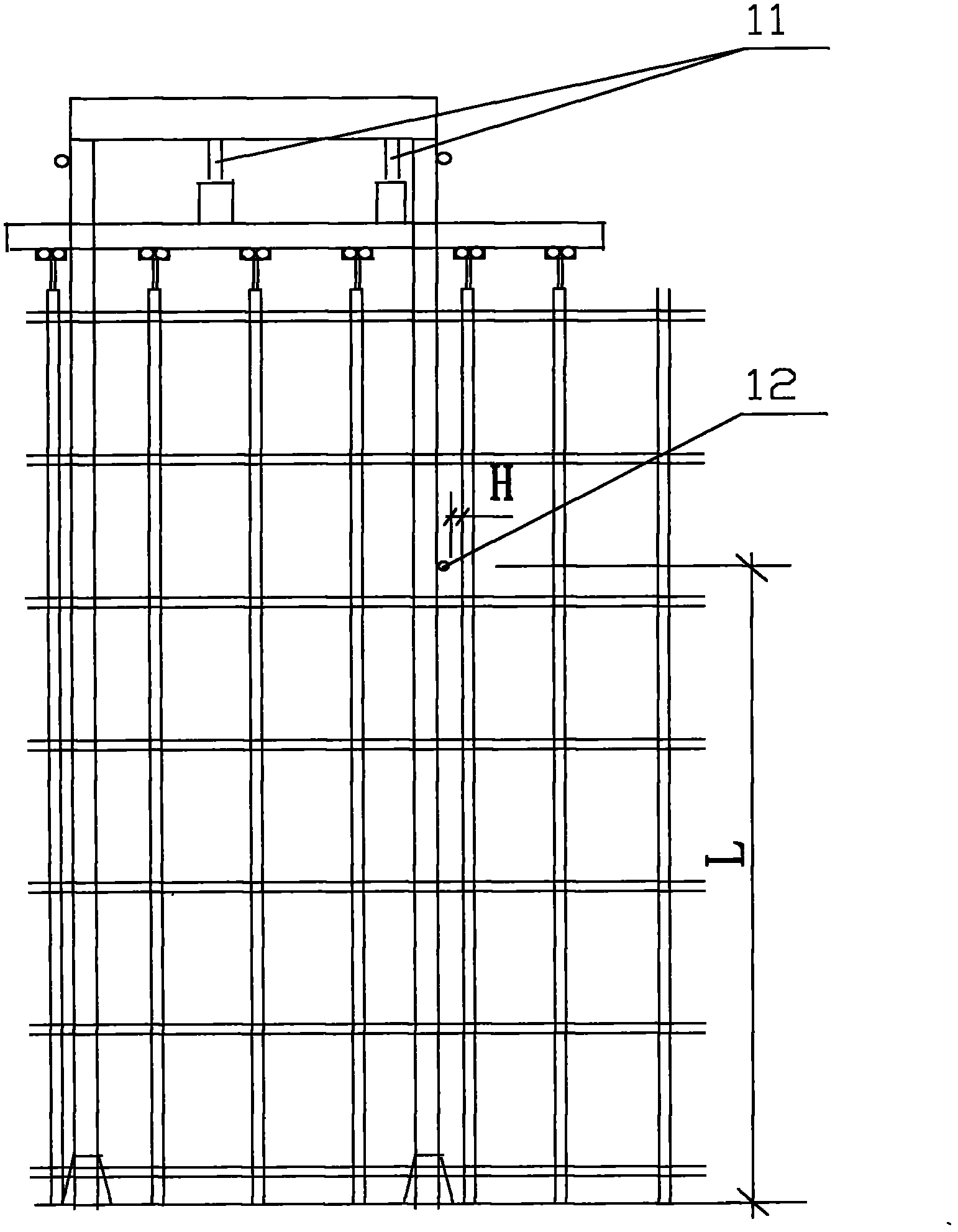

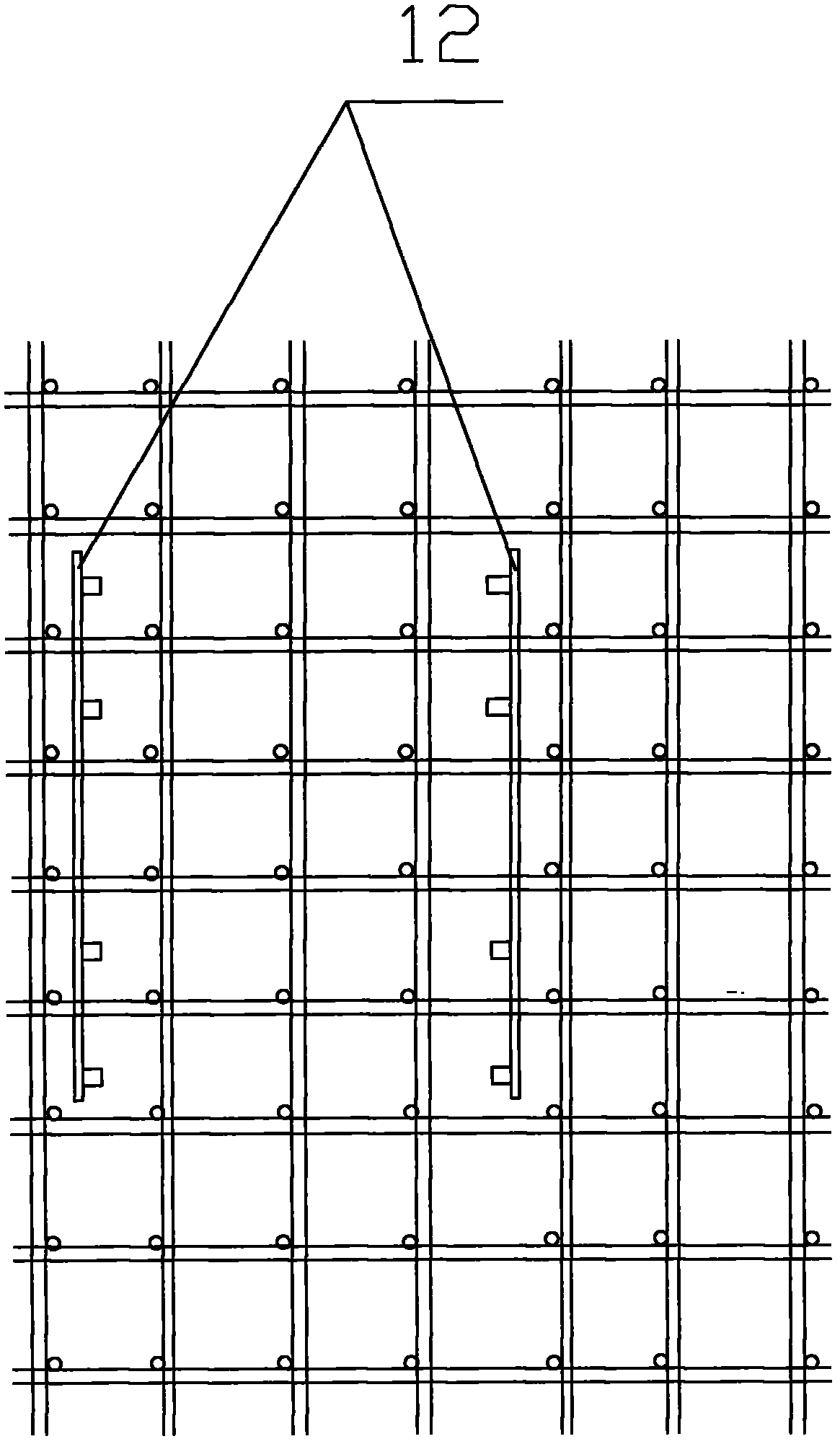

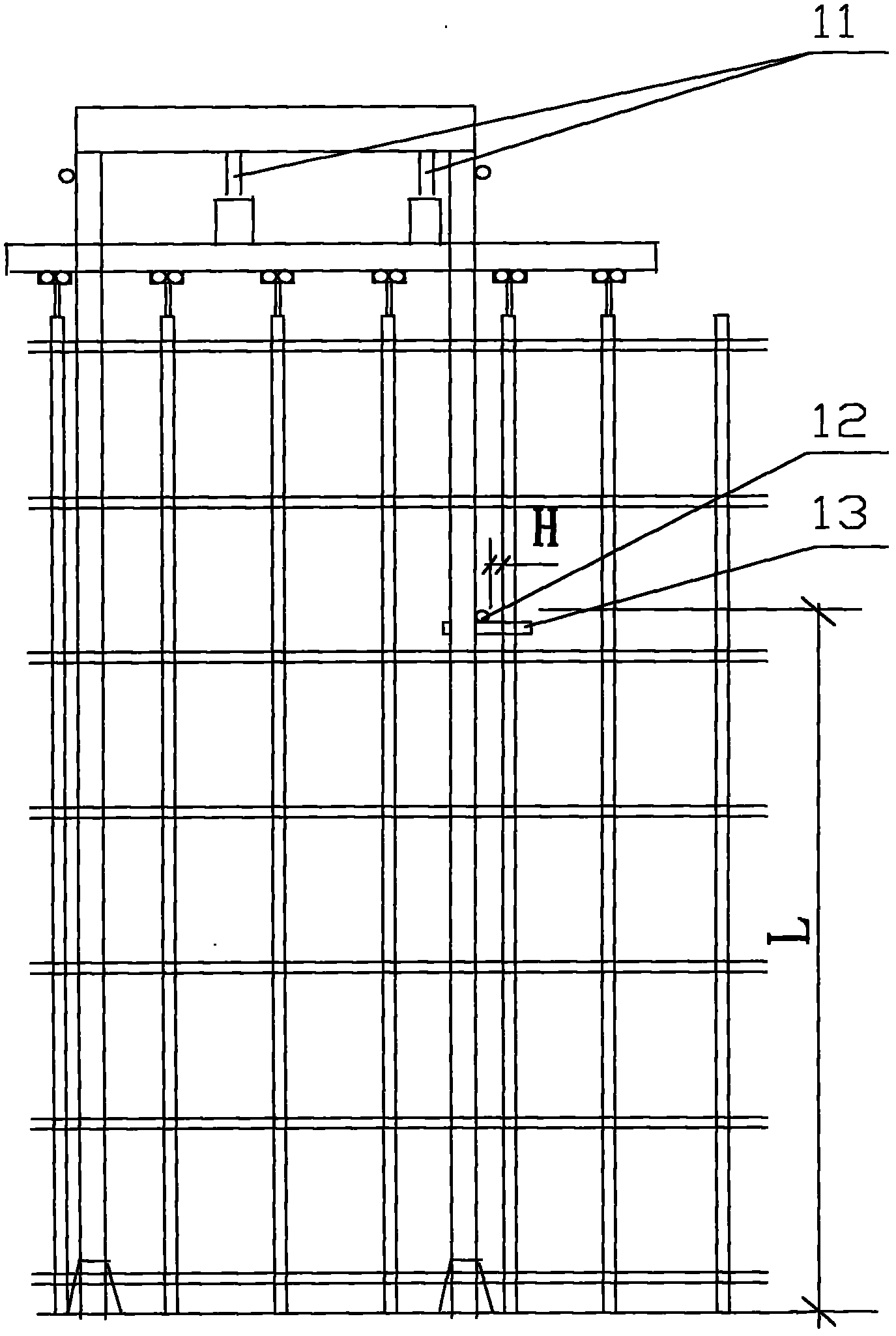

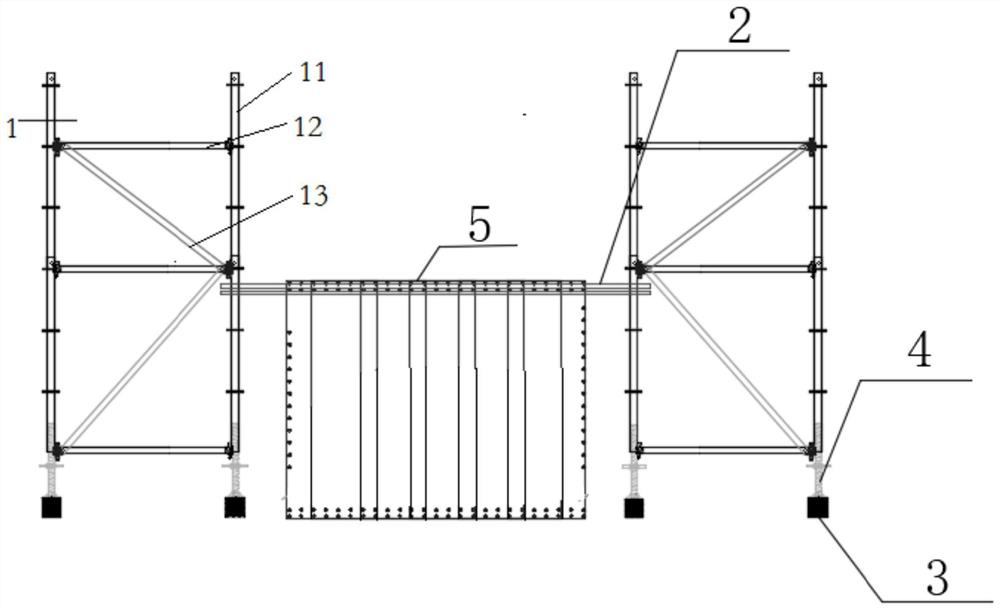

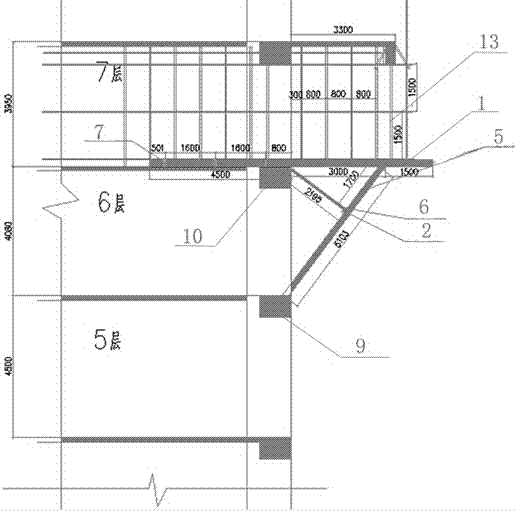

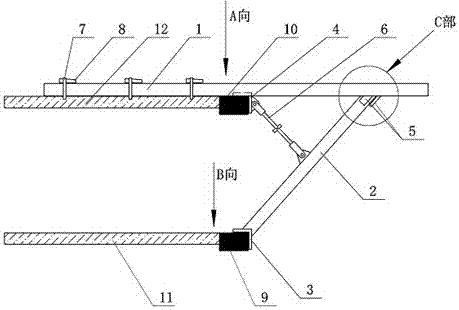

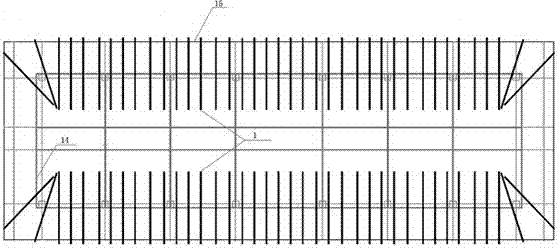

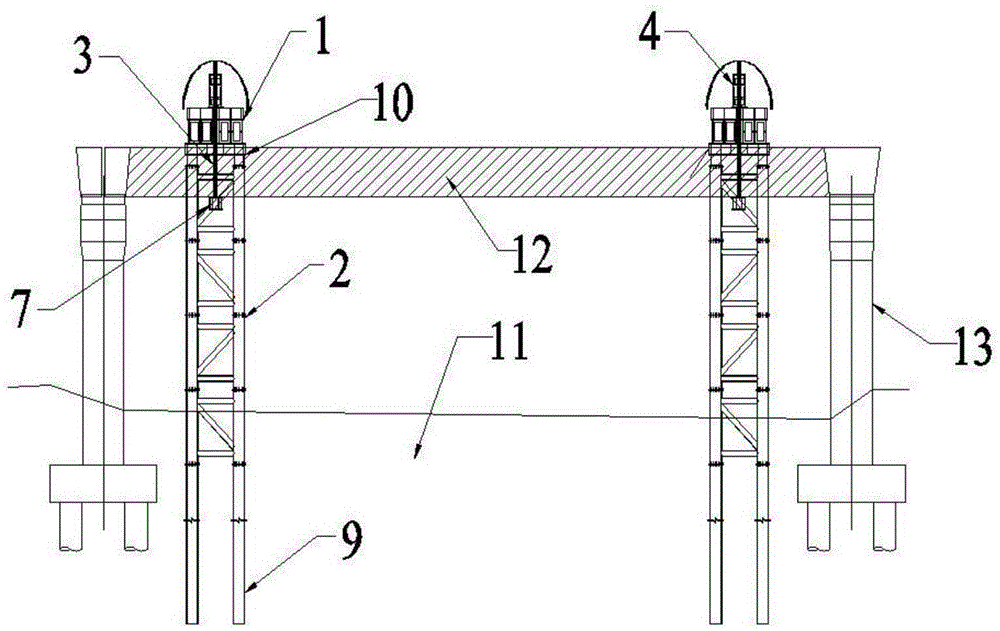

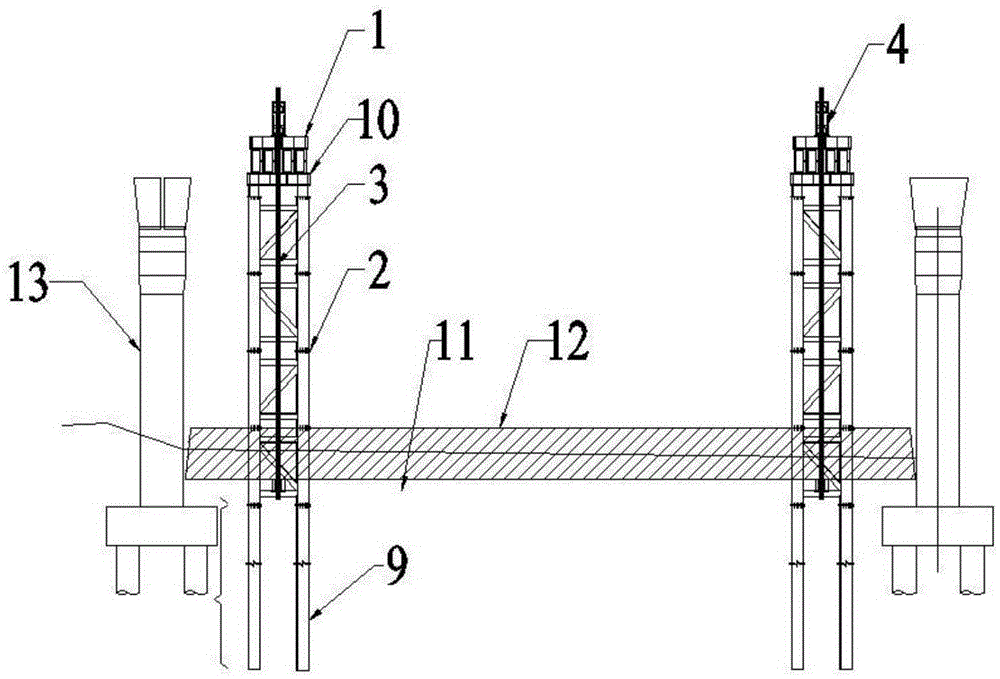

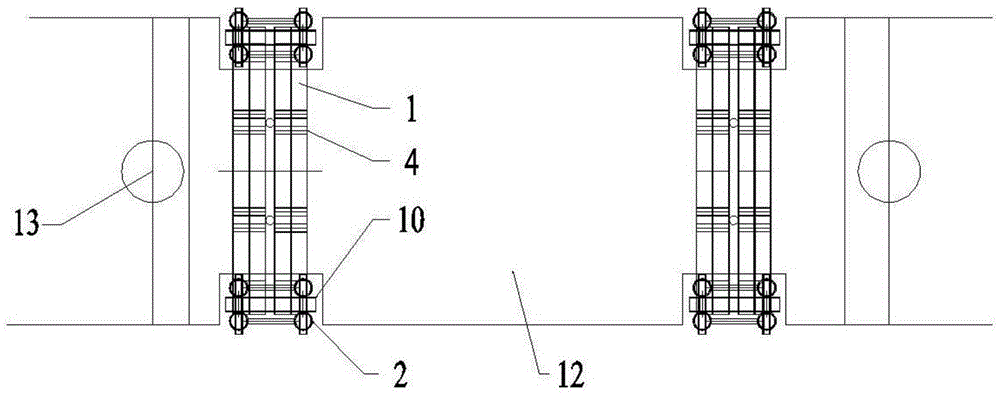

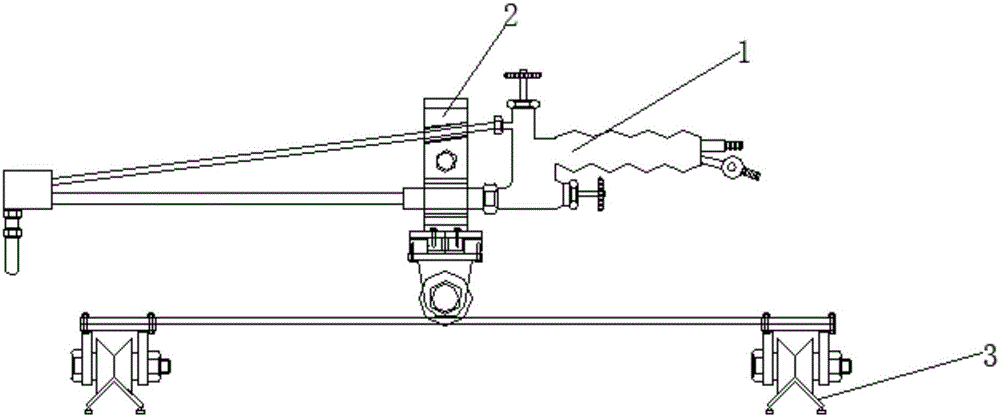

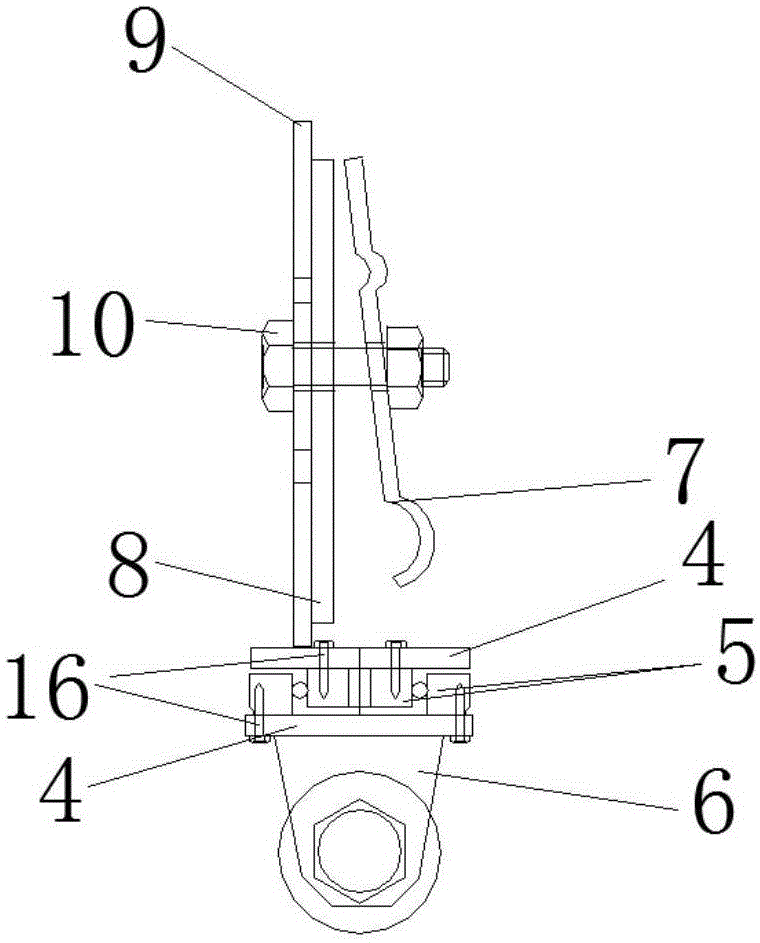

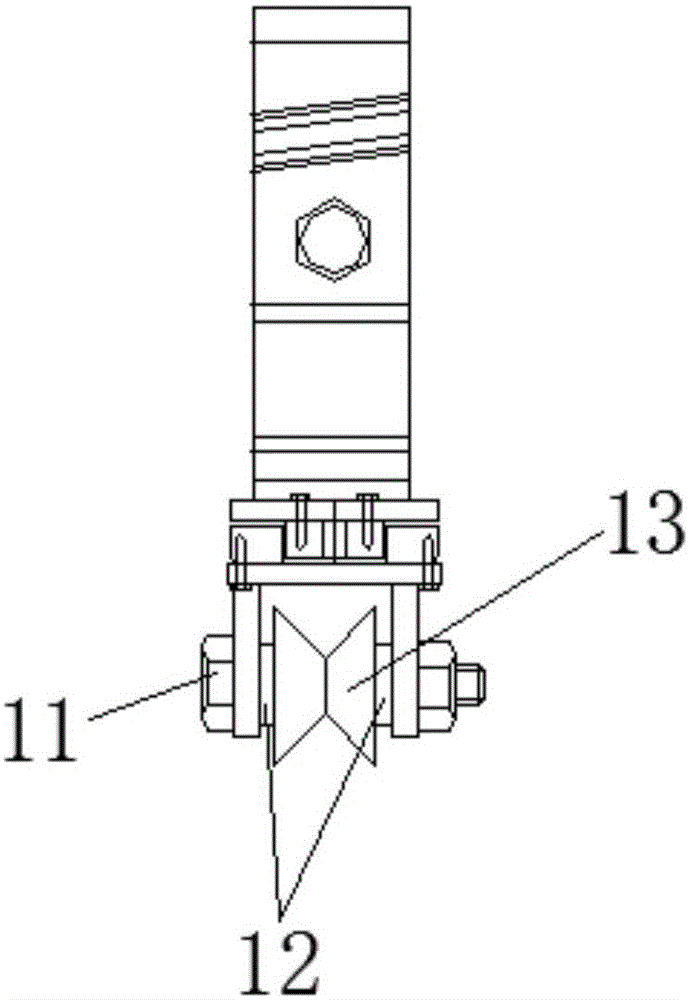

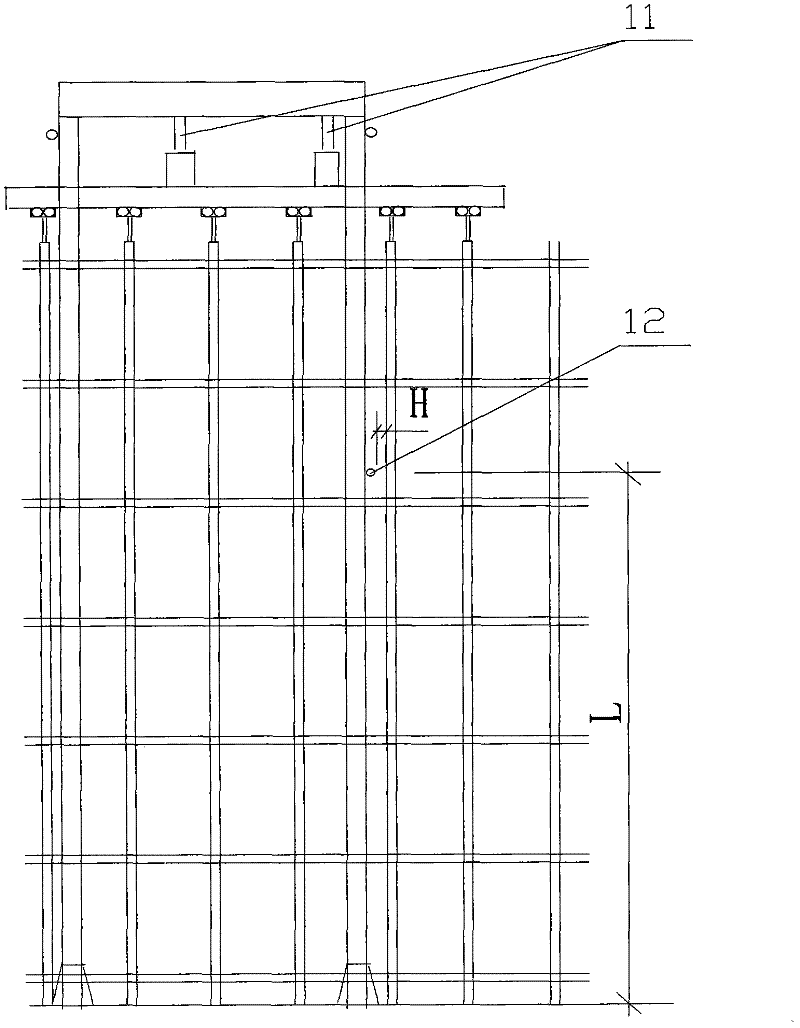

Whole striding bridge lowering dismounting system based on ground supporting and construction method thereof

ActiveCN104727236ASmooth downUniform lowering speedBuilding repairsBridge strengtheningEngineeringSupport plane

The invention relates to the field of bridge dismounting, in particular to a whole striding bridge lowering dismounting system based on ground supporting and a construction method thereof. The system comprises at least two sets of supporting structures used for supporting a lowering box beam. Each supporting structure comprises a main beam and two supporting frames located at the two ends of the main beam, wherein the two ends of the main beam are fixed to the main supporting frames, the main beam is arranged in the transverse direction, a lowering power system is arranged at the upper end of the main beam and connected with a sling, and a pocket hoisting device used for hoisting the lowering box beam is arranged at the lower end of the sling. The system is simple in structure, convenient to operate and high in construction safety, environmental friendliness is achieved, energy is saved, and extremely high popularization value is achieved.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

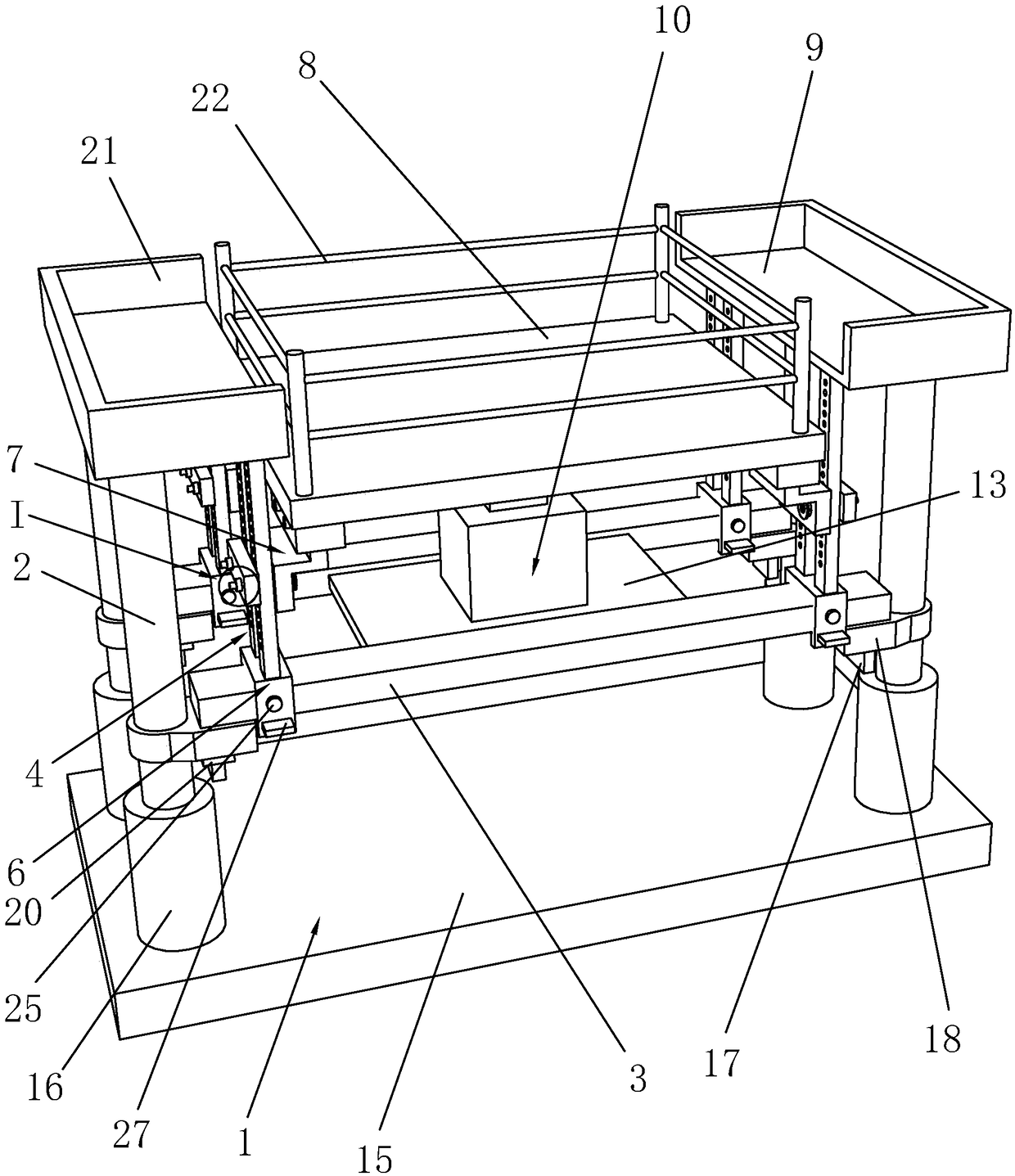

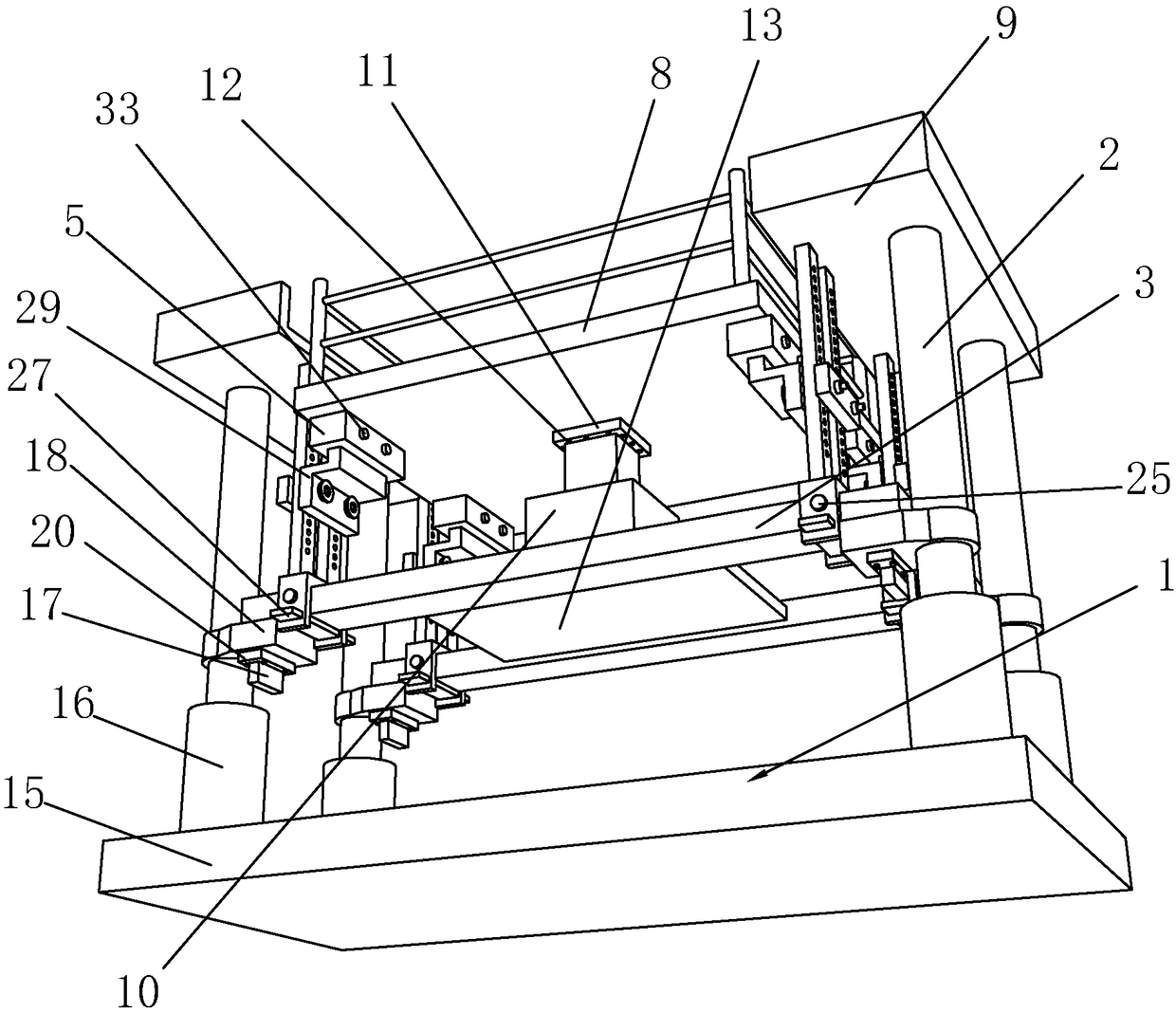

Supporting platform for building construction and installation method of supporting platform

PendingCN109339425ARealize automatic adjustmentImprove structural stabilityScaffold accessoriesUltimate tensile strengthSupport plane

The invention discloses a supporting platform for building construction. The supporting platform includes a supporting frame and a supporting table, the supporting frame comprises a supporting base, supporting columns, connecting rods and an adjusting frame, the supporting columns are uniformly arranged at the corners around the top face of the supporting base, the connecting rods are arranged between the left and right supporting columns correspondingly, the adjusting frame includes a fixing rod piece and an adjusting rod piece, and the supporting table includes a main supporting table and anauxiliary supporting table. An installation method includes the following steps that a, the supporting frame is installed; b, a hydraulic lifting column is installed; c, the supporting table is installed; and d, regular maintenance and overhaul are carried out. According to the supporting platform for building construction and the installation method of the supporting platform, overall design isreasonable, the structure is simple, building and disassembling are convenient, and the overall structural strength and stability of the supporting platform are high; and through design of the main supporting table and the auxiliary supporting table, the functionality and security of the supporting platform are additionally achieved, the main supporting table can facilitate standing of an operator, the auxiliary supporting table can facilitate placement of materials and tools, and meanwhile the height of the main supporting table can be adjusted up and down according to the actual demands.

Owner:ZHEJIANG UNIV OF TECH

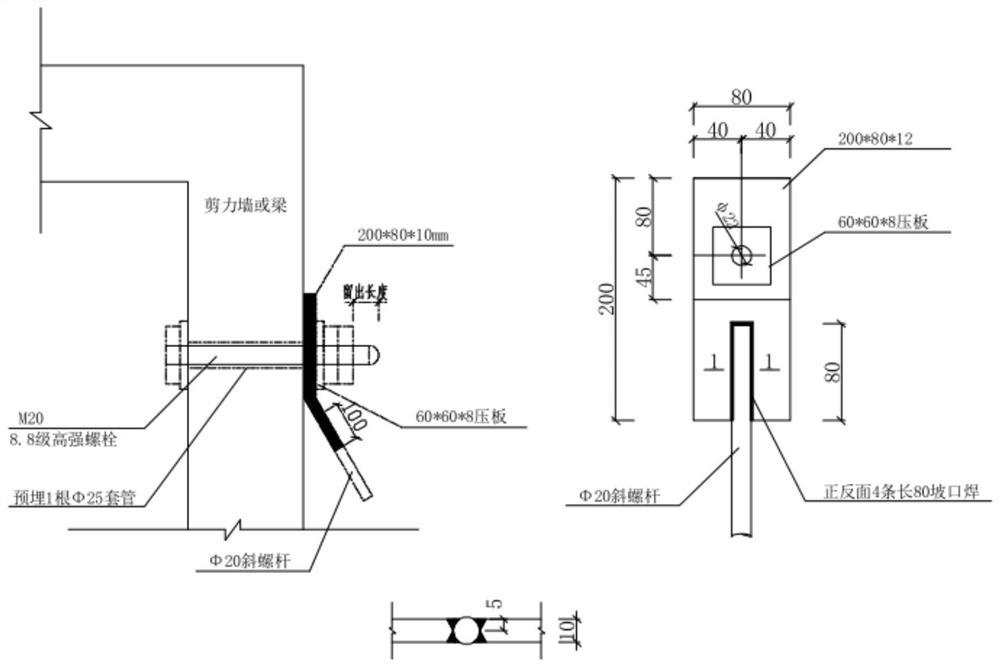

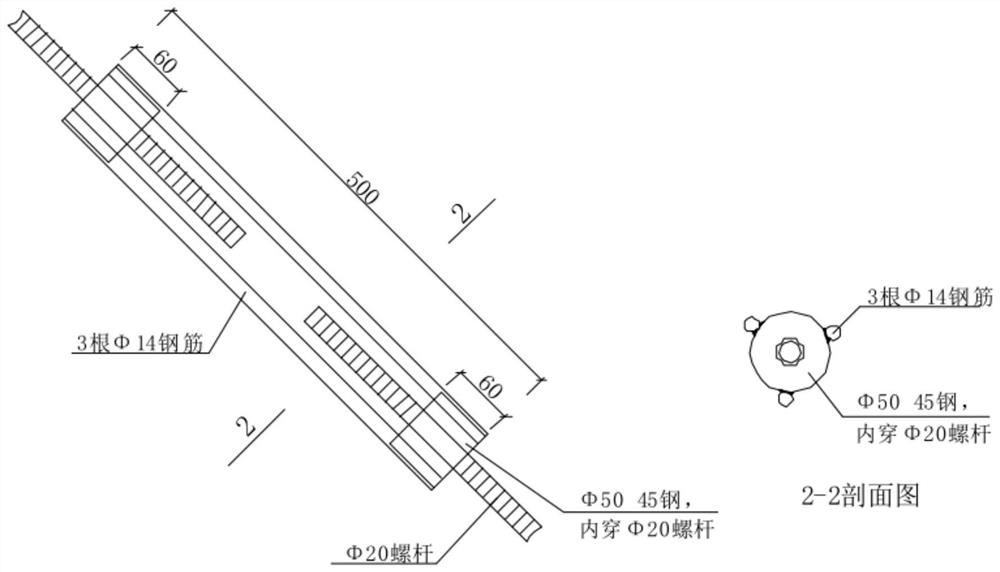

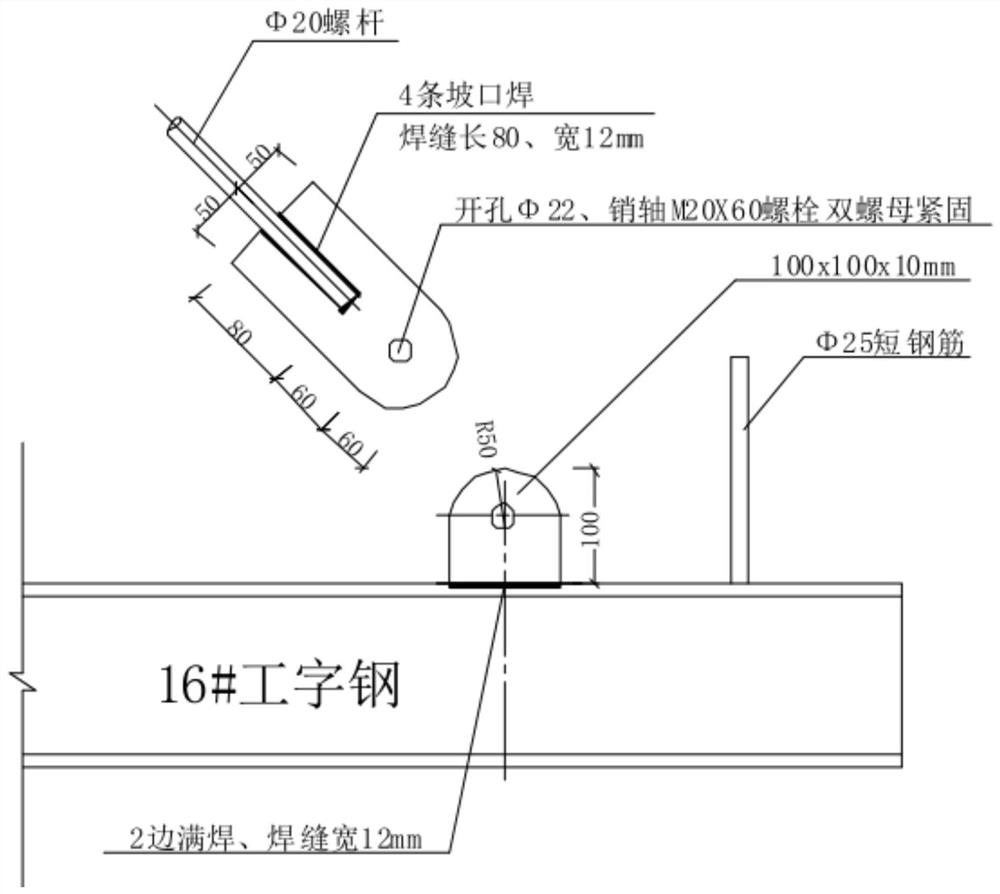

Installation method of basket diagonal draw bar type cantilever frame

InactiveCN111809850ALow costWide adaptabilityScaffold accessoriesBuilding support scaffoldsSafety netCantilever

The invention discloses an installation method of a basket diagonal draw bar type cantilever frame. The installation method comprises the following steps: carrying out set-up preparation work, manufacturing a cantilever frame body material, checking the cantilever frame body material, burying a sleeve in a wall ring beam, installing a cantilever I-shaped steel outrigger, arranging a cantilever I-shaped steel upward-pulling rod piece, arranging a vertical rod positioning point, erecting a scaffold sweeping rod, installing a basket diagonal draw bar, tightening a basket, adjusting the height ofan end of a cantilever beam, and carrying out maintenance; and arranging an embedded part, installing a cantilever main beam, arranging a cantilever main beam upper supporting rod and a cantilever main beam lower supporting rod, arranging a vertical rod positioning point, arranging a longitudinal sweeping rod, arranging a vertical rod, arranging a transverse sweeping rod, arranging a transverse horizontal rod, arranging a scissor support, arranging a wall connecting piece, laying scaffold plates, arranging protective barriers, and arranging a safety net. According to the installation method ofthe basket diagonal draw bar type cantilever frame, the manufacturing cost is low, the adaptability is wide, the bearing capacity is high, assembling and disassembling are facilitated, and the installation method is also suitable for complex building structures; and the installation method is environmentally friendly, can be used repeatedly, and is low in damage rate, and the cost is saved.

Owner:如皋市猛佳机械配件有限公司

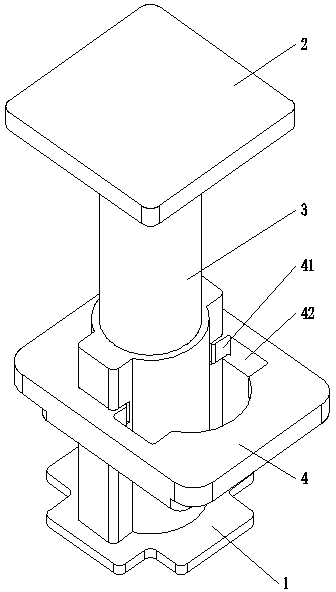

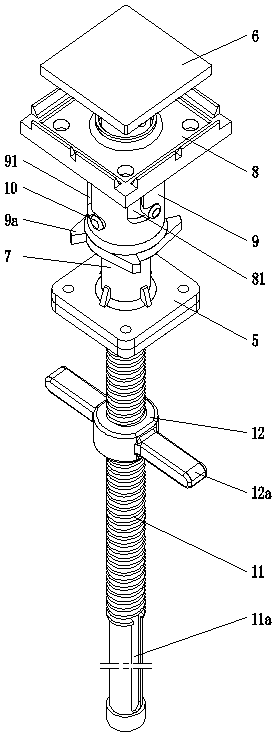

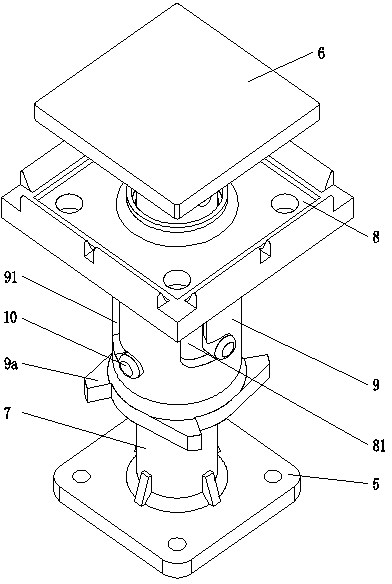

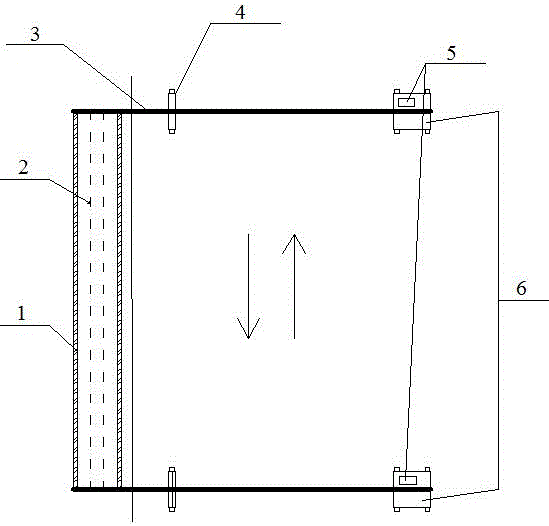

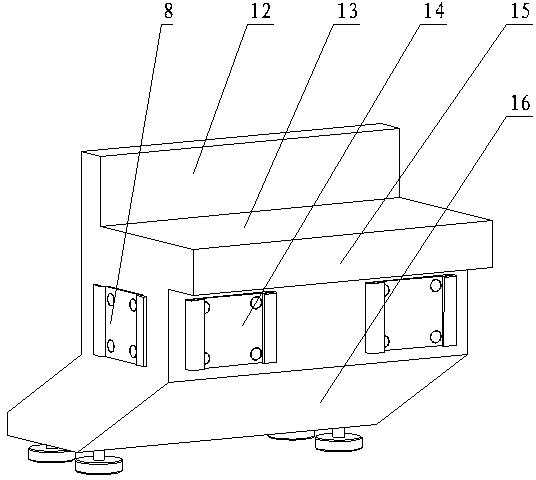

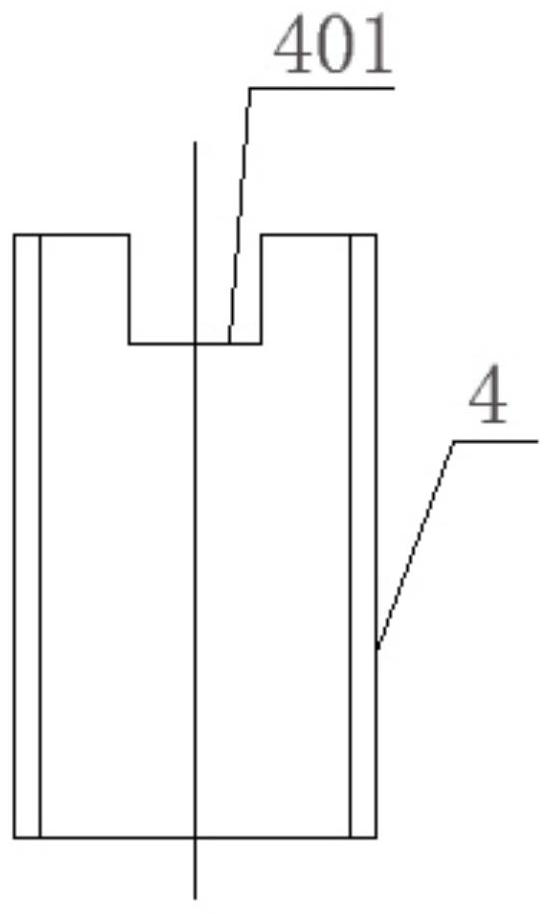

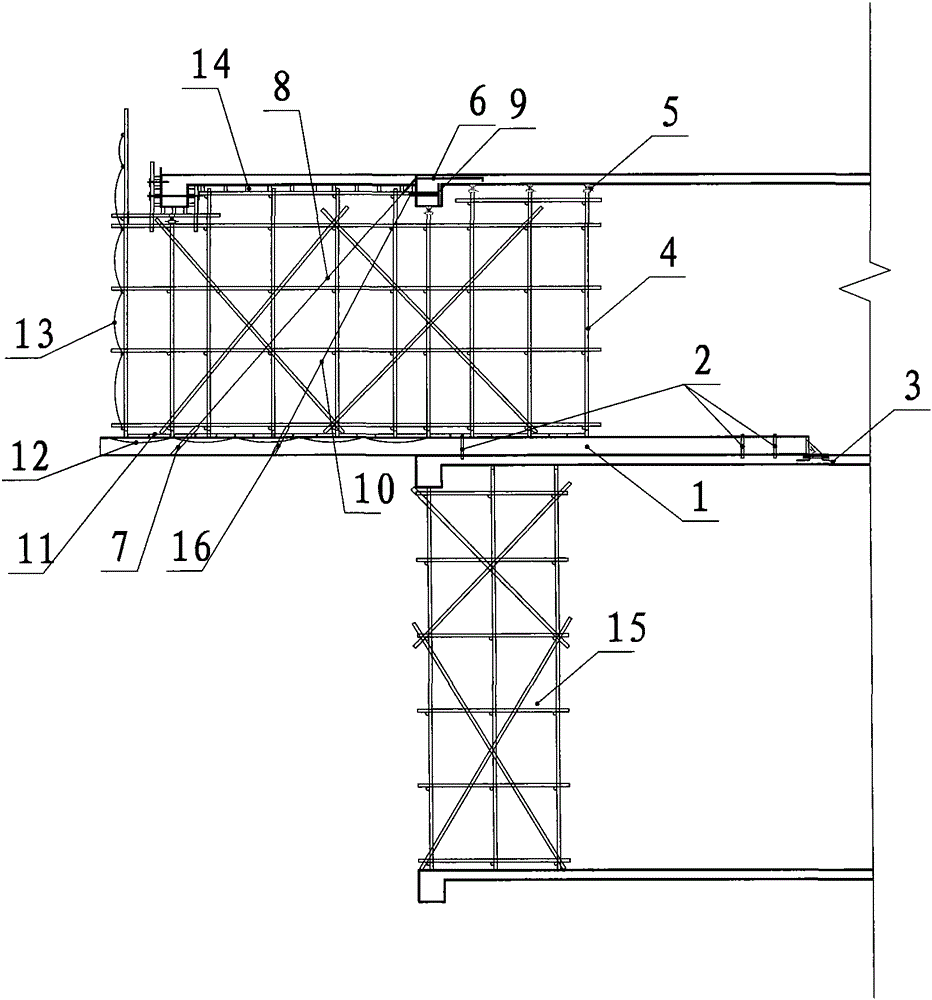

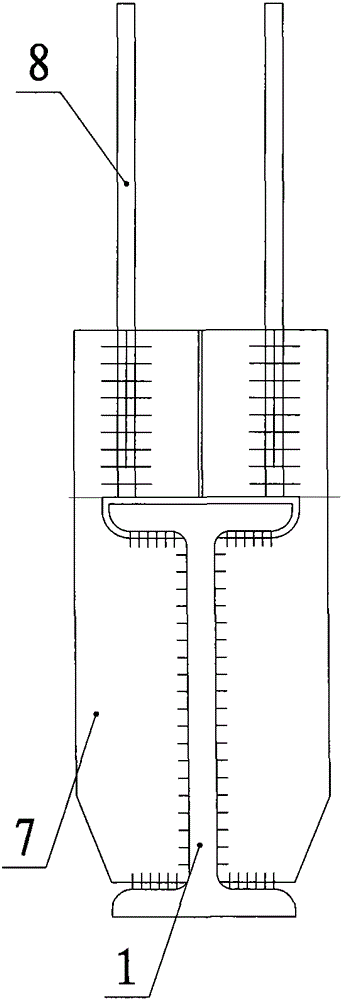

Formwork early removing mechanism and early removing formwork system

ActiveCN102787719BGood stability when removed earlyImprove efficiencyForms/shuttering/falseworksForm treatmentStructural engineeringManufacturing efficiency

The invention discloses a formwork early removing mechanism and an early removing formwork system. The early removing mechanism comprises a bottom plate, a top plate, a strut and a bracket; the strut is arranged between the bottom plate and the top plate; the bracket is slidably sleeved on the strut; a bracket supporting sleeve which can be driven to rotate by external force is arranged below the bracket; vertical guide grooves are arranged on a tubular wall of guide sleeves of the bracket; the bracket supporting sleeve is movably annularly sleeved on the peripheries of the guide sleeves of the bracket; a tubular wall of the bracket supporting sleeve is provided with slide grooves which extend upwards along the tubular wall; a horizontal section is arranged at the lower end of each slide groove; hinge pins are transversely and penetratingly arranged on the strut; overhanging portions of the hinge pins are arranged in the guide grooves of the guide sleeves and the slide grooves of the bracket support sleeve in a clearance fit manner; and when the hinge pins are positioned in the horizontal sections of the slide grooves, the bracket is supported by the bracket supporting sleeve, and the lower ends of the guide grooves are matched with the hinge pins. The early removing formwork system is provided with the formwork early removing mechanism. The formwork early removing mechanism and the early removing formwork system have the advantages that the early removing mechanism is high in early removing stability and efficiency; and the early removing formwork system is high in processing and manufacturing efficiency, stable and convenient to erect and detach, high in efficiency, and low in labor intensity, and saves transfer labor.

Owner:泰博新型建筑科技(苏州)有限公司

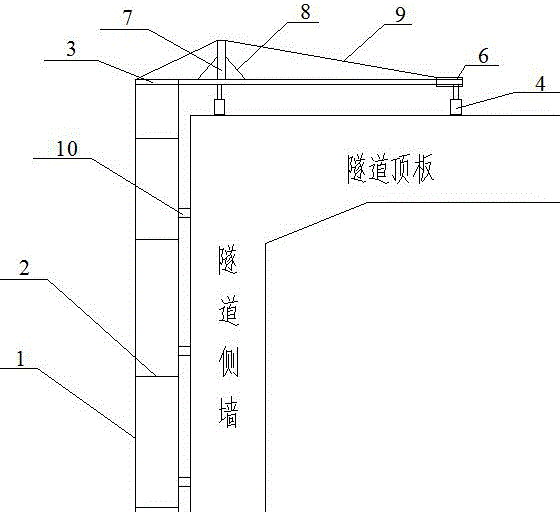

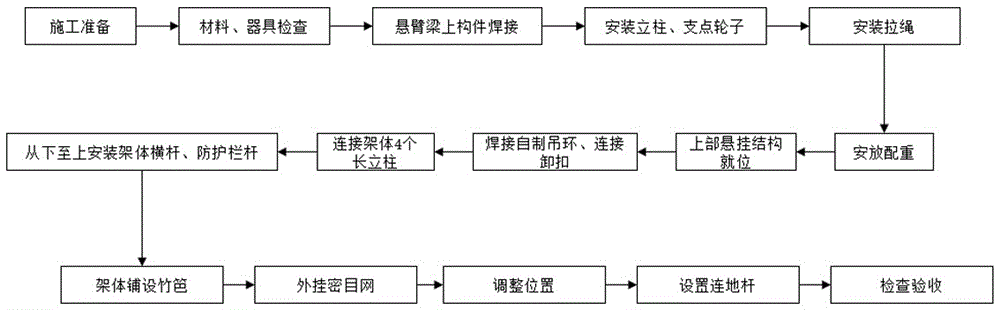

External wall construction hanging bracket and installation method thereof

InactiveCN107524285AResolution timeSolve manual problemsBuilding support scaffoldsFalseworkEngineering

The invention provides an external wall construction hanging bracket and an installation method thereof. The external wall construction hanging bracket and the installation method thereof are used for solving the technical problems that decorative construction operation of a side wall or a building external wall in an open trench tunnel is not convenient, whole movement cannot be achieved, and scaffold erecting consumes time and labor. The external wall construction hanging bracket comprises a suspension structure, a bracket body and a plurality of sets of operating platforms. The suspension structure is connected with the bracket body, and the multiple sets of operating platforms are arranged on the bracket body; the suspension structure comprises a suspension cross beam, an upright post, a suspension wire, a counter weight and a counter weight storing platform, the bracket body comprises a bracket body framework, a guardrail and a ground-connecting piece, the suspension cross beam is arranged on the counter weight storing platform, and the upright post is arranged on the suspension cross beam; and the two ends of the suspension wire are arranged at the two ends of the suspension cross beam after passing through the upright post, the suspension cross beam is connected with the bracket body framework 1 through a connecting buckle, and an adsorption device is arranged on the guardrail. According to the external wall construction hanging bracket and the installation method thereof, the problem that erecting and removing of a fixed type scaffold consume a large amount of time and labor in the construction and decoration process of the external wall of the open trench tunnel is solved, and the external wall construction hanging bracket and the installation method thereof have the advantages that erecting and removing are simple and convenient, the stress is reasonable and stable, the construction speed is high, and the efficiency is high.

Owner:CHINA CONSTR SENVENTH ENG BUREAU INSTALLATION ENG

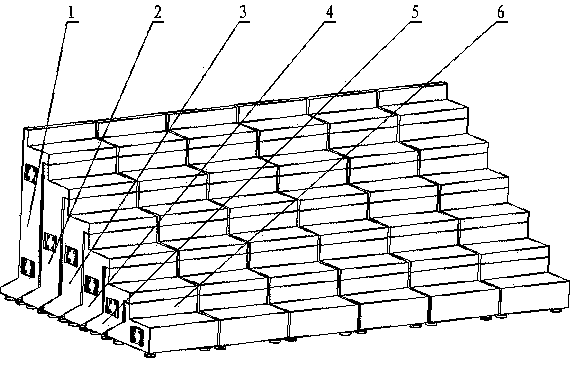

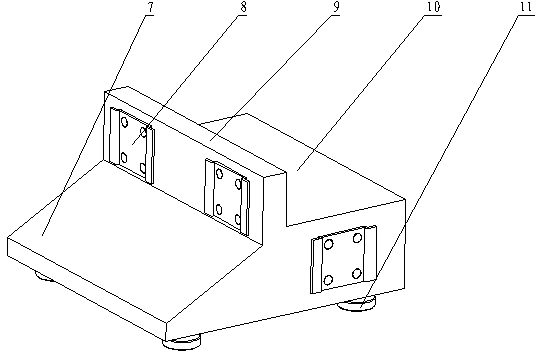

Combined stand

The invention provides a combined stand which is easy and convenient to mount and dismount, easy to transport, firm in structure, complete in function and capable of meeting the requirement for moving stands in the modern social activity. The combined stand is characterized in that the front row of the stand is provided with head platforms connected through positioning buckles, positioning buckles A on the front lower edges of second platforms are connected with the positioning buckles B on the back faces of baffles of the head platforms, the front edges of the second platforms are placed on the tops of the baffles of the head platforms, front slopes of the second platforms are connected with back slopes of the head platforms in an inclined mode, and the second platforms are connected through positioning buckles; the whole stand is formed by connecting the layers.

Owner:江苏源丰智能科技有限公司

Method for increasing wall connecting piece and improving and determining bearing capacity of support frame

InactiveCN102182311ASimple structureImprove bearing capacityBuilding material handlingScaffold accessoriesCritical loadWidth ratio

The invention relates to a method for increasing horizontal restraint and improving and determining bearing capacity of a support frame. The support frame is loaded in a 5-span * 5-span range in a mode of longitudinal 8 spans and transverse 6 spans; the support frame is loaded in a mode of 2 spans on one longitudinal side and 1 span on the other side outside the loading area; the support frame is loaded in a mode of 1 span on one transverse side outside the loading area; the height of the frame is 8.2 meters, the step pitch of upright rods is 1.24 meters, the longitudinal distance between the upright rods is 0.9 meter, the transverse distance between the upright rods is 0.9 meter, the height-width ratio of a bracket is 1.5, and the support frame is erected by using phi48*3.2 steel pipes; and adjustable bracket jacking phi48*3.2 double steel pipes are used as supporting load main beams on the upper part of the bracket, the distance between the upper surface of an adjustable bracket and the top transverse pipe of the bracket is 0.55 meter, the adjustable bracket extends out of the upright rods for 0.3 meter, a horizontal restraint rod is arranged on a reaction frame at the height of 5.3 meters, the distance between the horizontal restraint rod and the nearest upright rod is 12 to 15 centimeters, and the critical load loaded to the support frame is 24kN. By the method, the fastener support frame has economic and reasonable structure, and is safe and practical.

Owner:ZHONGTAI CONSTR GROUP

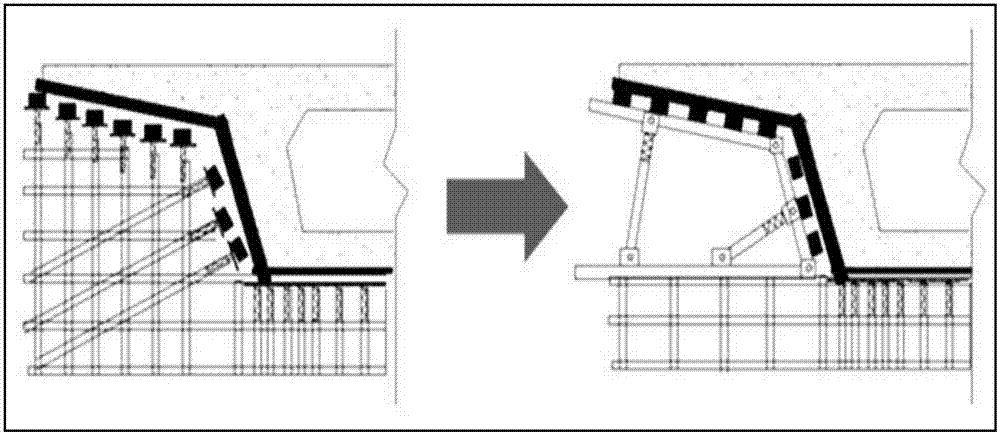

Cast-in-place box girder side web plate and wing plate integration supporting frame

InactiveCN106906752AEasy to controlSave materialBridge erection/assemblyBox girderBuilding construction

The invention relates to a cast-in-place box girder side web plate and wing plate integration supporting frame. An under-frame is horizontally arranged, one end of a web plate supporting rod is connected with one end of the under-frame in a movable mode, the other end of the web plate supporting rod is connected with one end of a wing plate supporting rod in a movable mode, one end of a wing plate adjusting rod is connected with the other end of the under-frame in a movable mode, and the other end of the wing plate adjusting rod is connected with the other end of the wing plate supporting rod in a movable mode; one end of a web plate adjusting rod is connected with the waist part of the web plate supporting rod in a movable mode, and the other end of the web plate adjusting rod is connected with the under-frame in a movable mode; the lengths of the web plate supporting rod, the wing plate adjusting rod and the web plate adjusting rod are adjustable. According to the cast-in-place box girder side web plate and wing plate integration supporting frame, a side web plate and wing plate bracket of a cast-in-place box girder is separated from the whole to be designed as a tool-type bracket, compared with traditional brackets, the bracket is simpler and quicker and convenient to control, the technical problem is solved that the box girder side web plate and wing plate bracket is tedious to construct and dismount in a construction process, and materials are saved..

Owner:北京城建远东建设投资集团有限公司

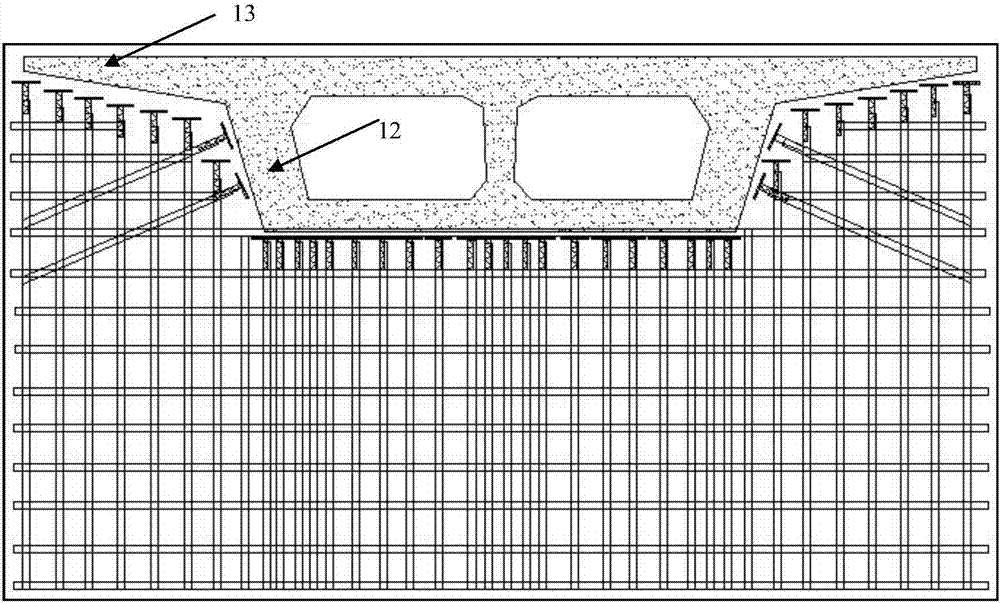

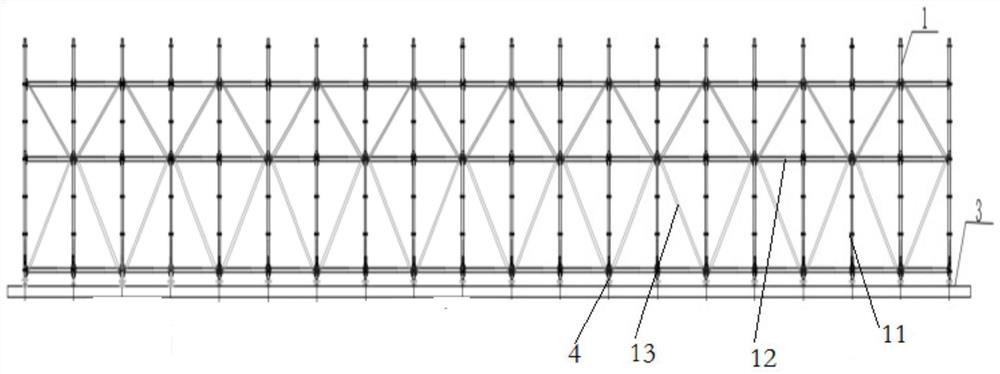

Cast-in-place box beam and cross beam multi-layer steel bar installation supporting system device and construction method thereof

The invention provides a cast-in-place box beam and cross beam multi-layer steel bar installation supporting system device and a construction method thereof. The cast-in-place box beam and cross beam multi-layer steel bar installation supporting system device comprises a supporting cushion structure. The adjustable bottom support is arranged on the supporting cushion structure; the disc buckle frame body is detachably connected with the adjustable bottom support; and the supporting cross rod is arranged on the disc buckle frame body. The whole device is simple in structure, stable, reliable and high in operability; the construction method is easy to operate, high in speed and remarkable in work efficiency; standardized manufacturing can be conducted, erecting and disassembling are convenient and safe, cyclic utilization is achieved, cost is saved, and the construction period is shortened; the whole device is clear in force transmission, high in bearing capacity and good in stability, effectively solves the problems of temporary supporting and positioning during binding and mounting of multiple layers of reinforcing steel bars of the cast-in-place box girder and the problem of operation of operators in a reinforcing steel bar cage, and greatly guarantees construction safety in the reinforcing steel bar mounting process.

Owner:CHINA MCC5 GROUP CORP

High-altitude suspended formwork and its construction method

ActiveCN105019639BHigh cantilevered spanLong cantilevered spanScaffold accessoriesBuilding support scaffoldsFloor slabSupport point

The invention discloses a high-altitude cantilever formwork and a construction method thereof. The bottom angle steel is fixed on the side of the n-story beam of the structure as the support point of the diagonally braced I-beam, and the fixed top angle steel is welded in the middle of the cantilever I-beam. The top angle steel Matching and fastening with the corners of the beams on the n+1 floor; Welding the inherently braced I-steel support at the end of the cantilevered I-steel or near the end. During the construction of the n+1-story structure, the floor slab will There are at least two steel pressure rings, and each round steel pressure ring is firmly welded to the cantilevered I-beam, or fixed with a wooden wedge. The high-altitude cantilever structure of the present invention is characterized in that the parts of the cantilever components are high from the ground. The cantilevered structural members have a long cantilever span, and the disturbance caused by the self-weight of the structure is large. The location of the welding point between the diagonally braced I-beam and the horizontal I-beam cantilevered platform should be determined according to the length of the cantilever, and the best force-bearing position is within 1 / 3 of the outer edge of the span of the cantilevered member.

Owner:HENAN GUOJI CONSTR GRP

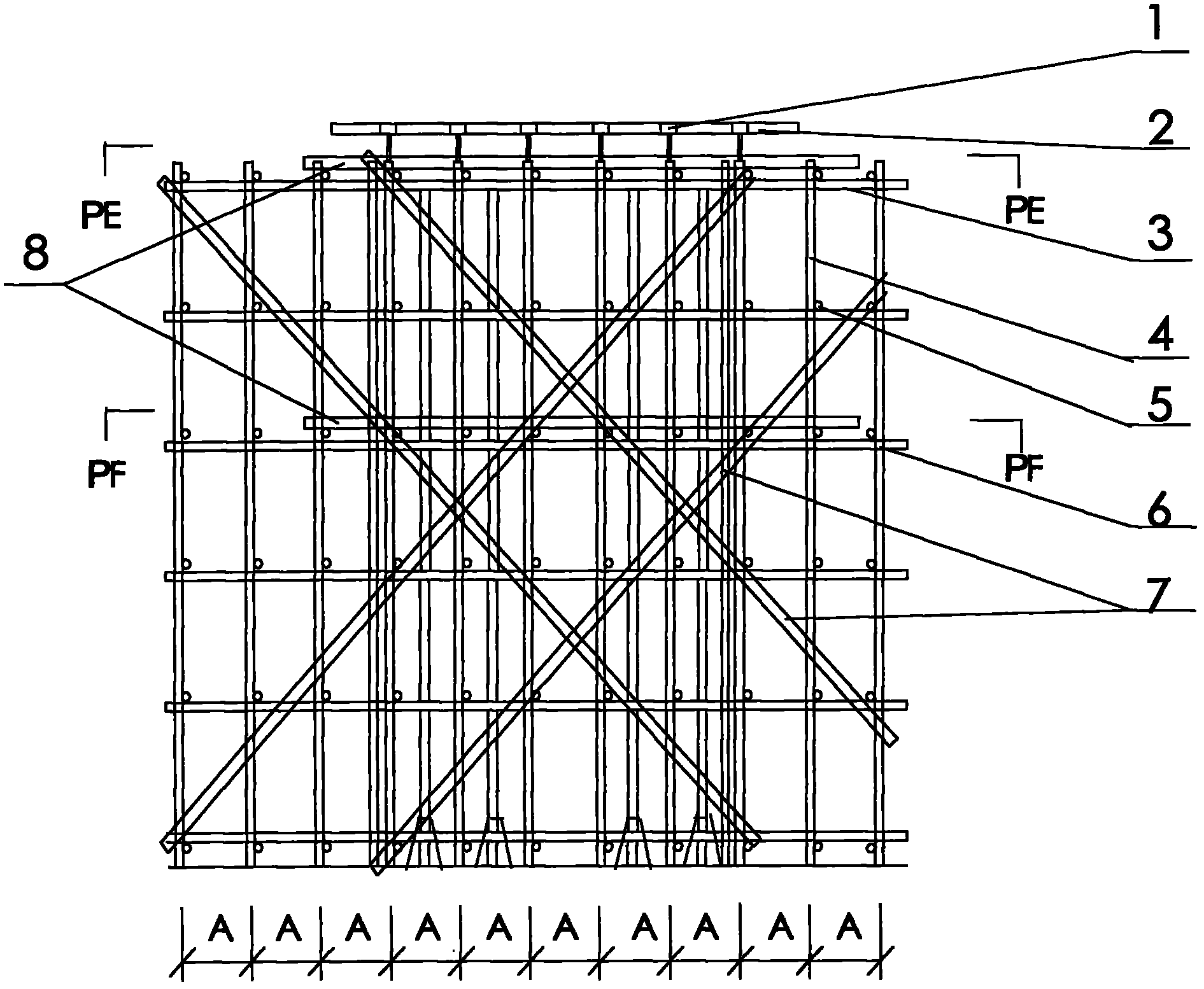

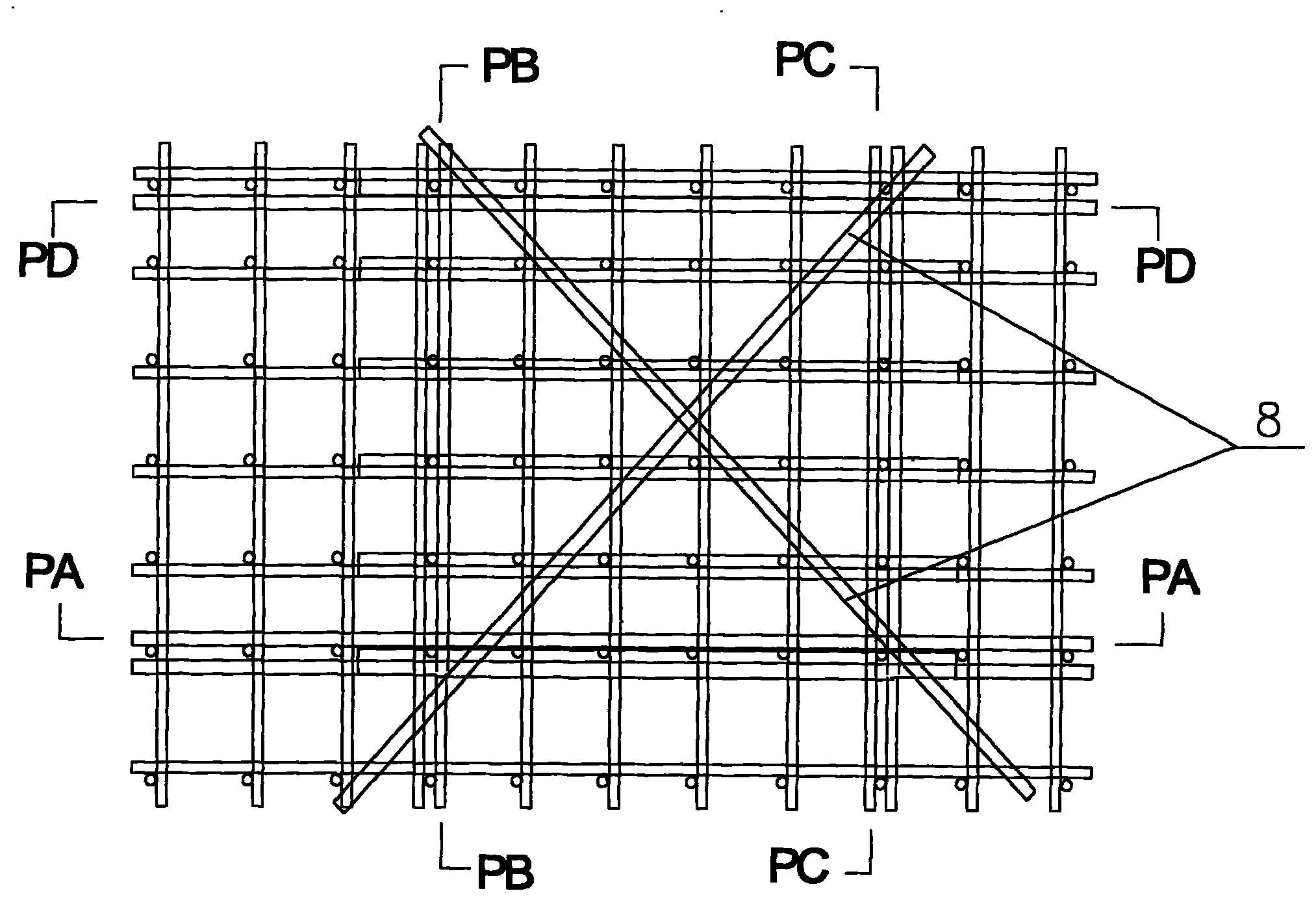

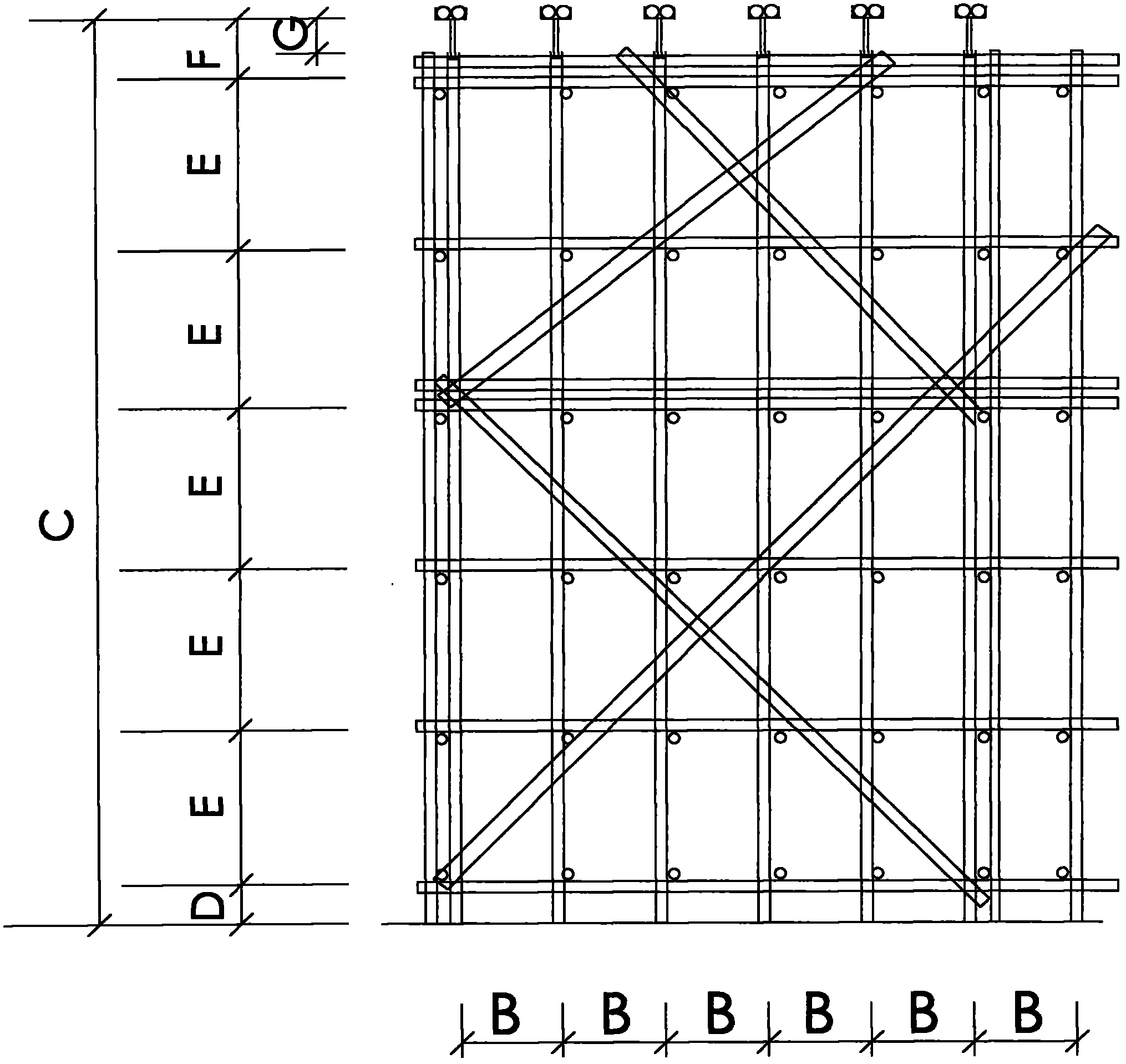

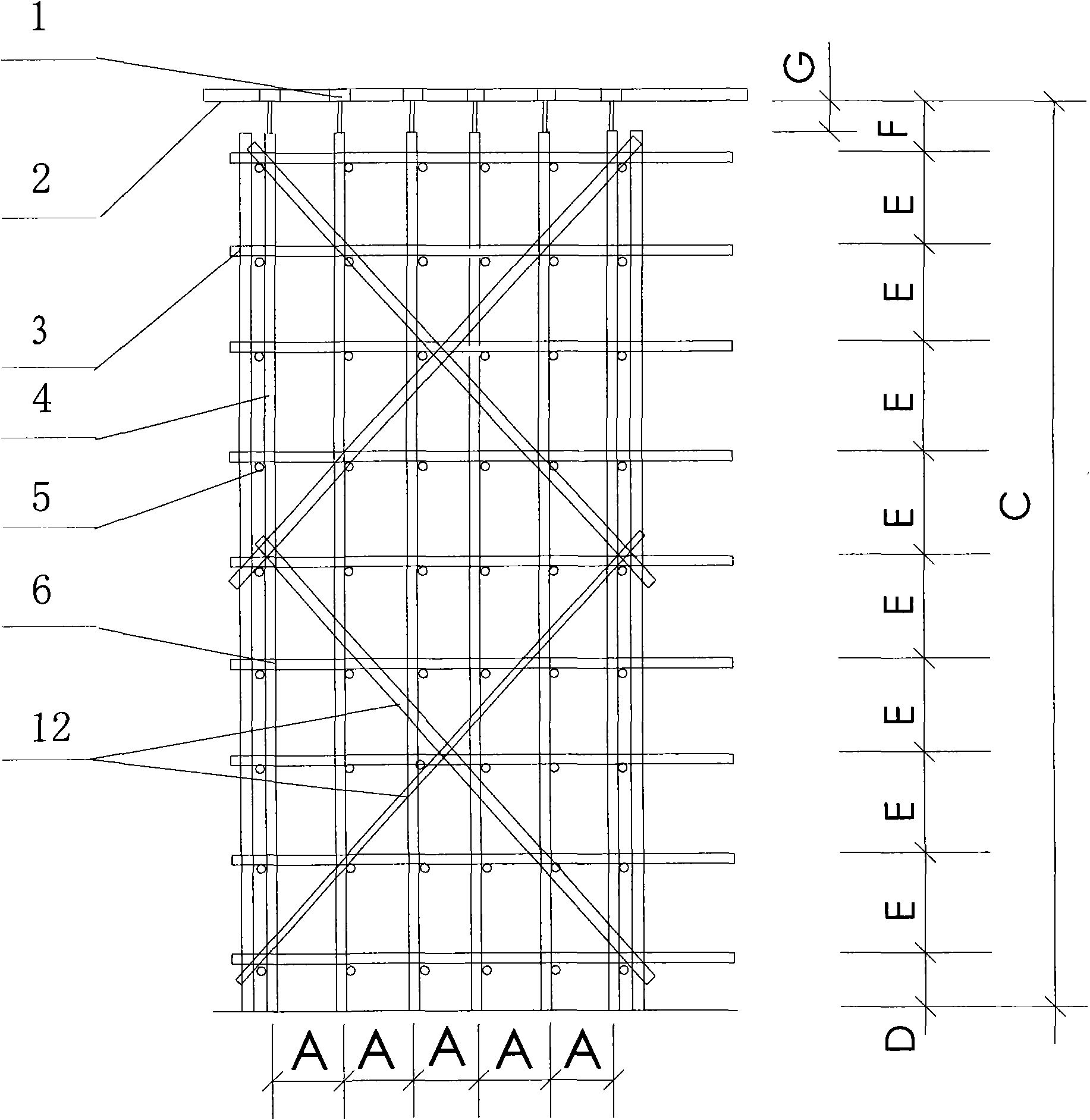

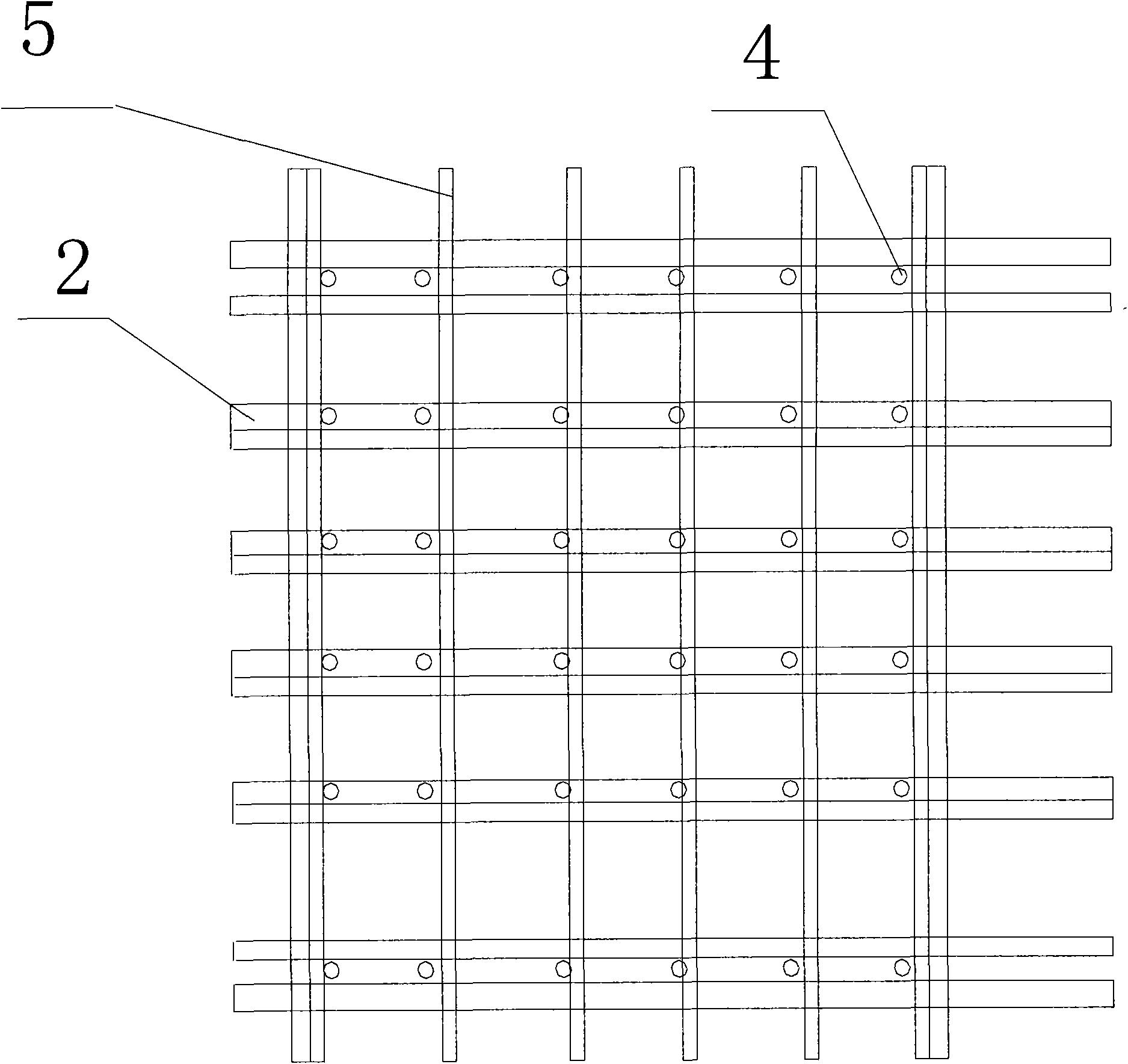

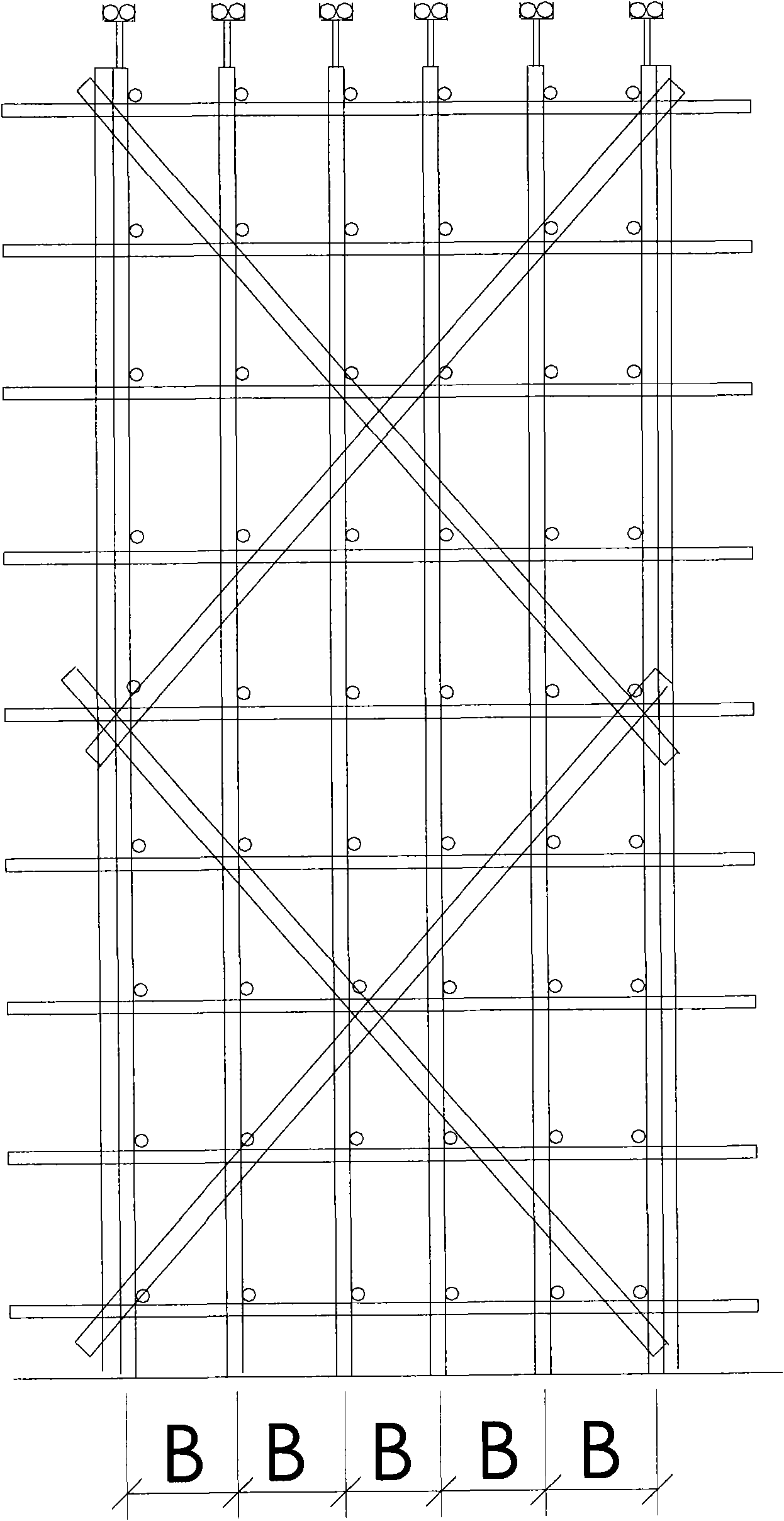

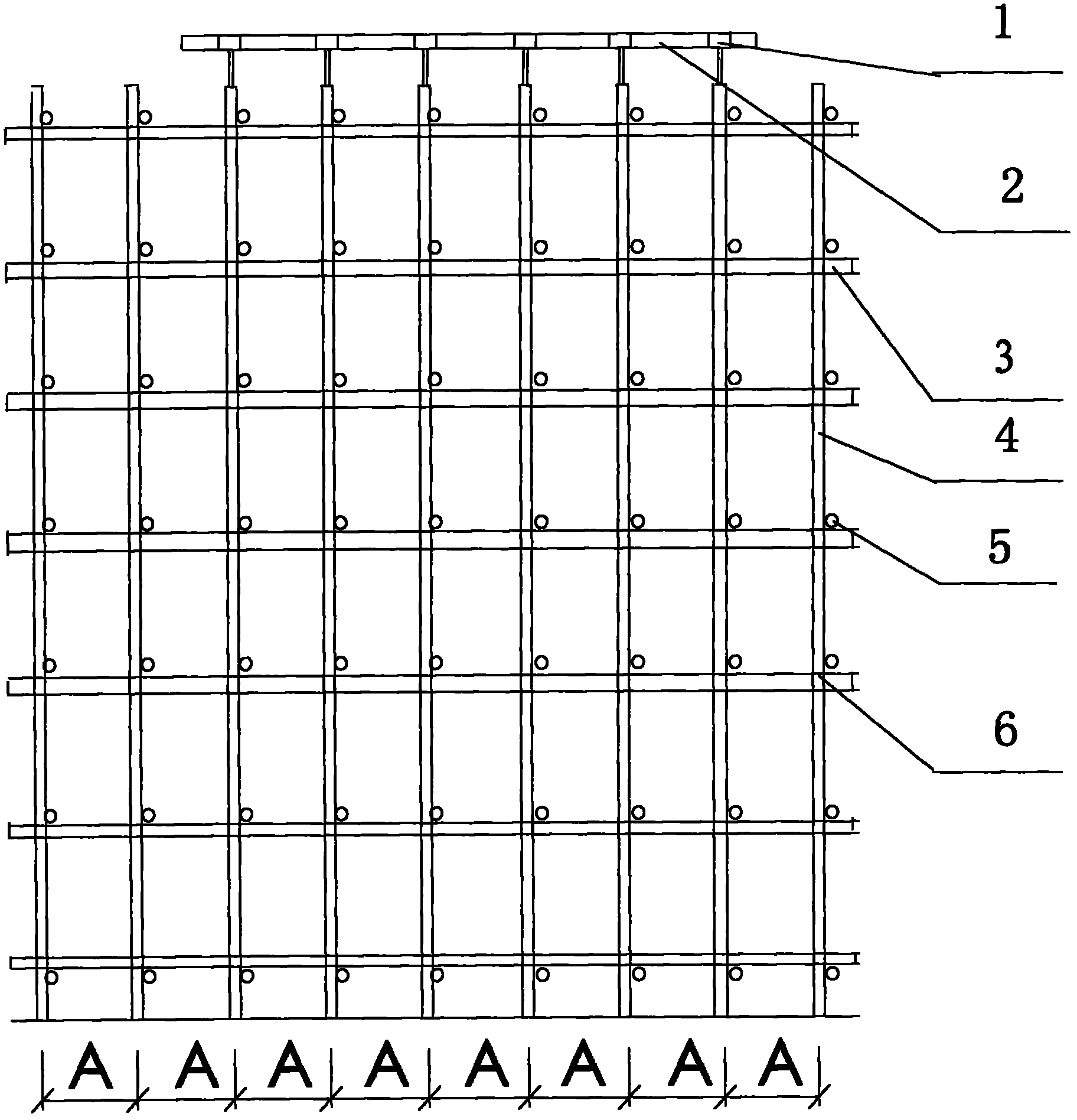

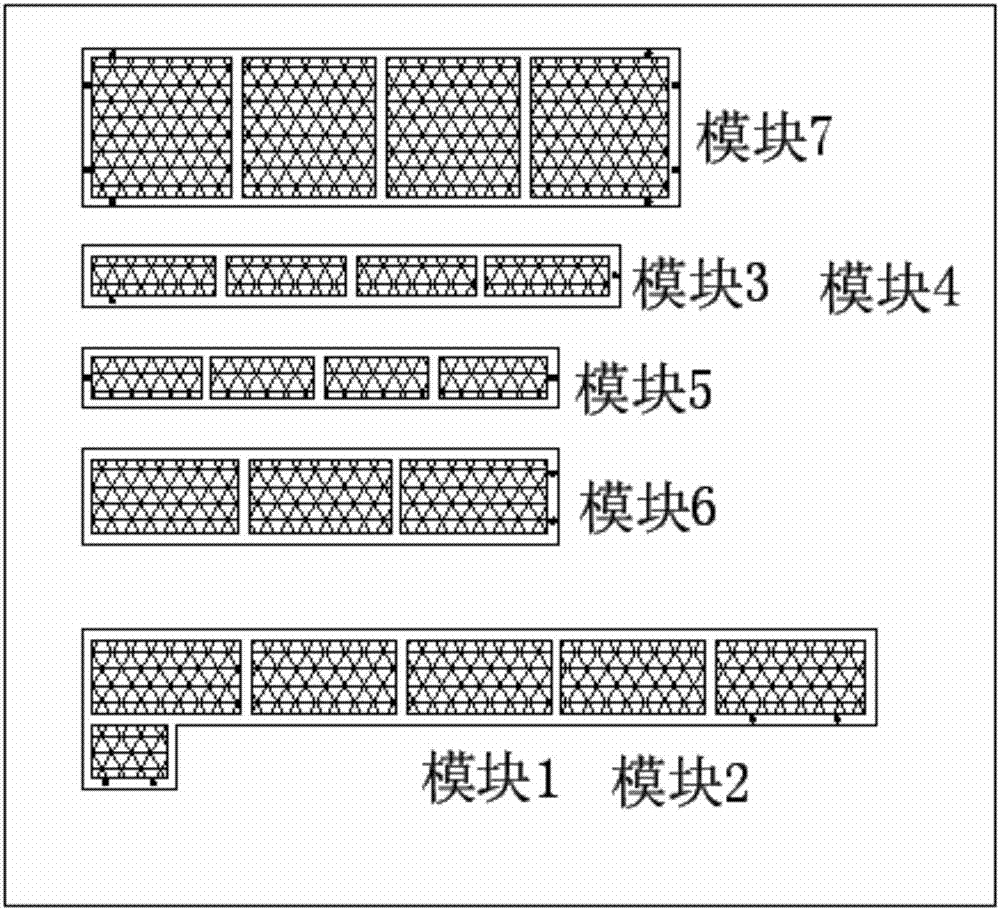

Buckled type steel pipe scaffold formwork support of cross strut

ActiveCN101560828ASafe and stable structureSimple structureForms/shuttering/falseworksSteel tubeWidth ratio

The invention relates to a buckled type steel pipe scaffold formwork support, wherein five spans are available longitudinally and also horizontally and loading is conducted within the range of 5 spans multiplied by 5 spans; each vertical face around the periphery of a loading area is provided with a vertical cross strut at every four rows of vertical uprights and the cross strut is arranged close to joints and the junction of the cross strut and a cross rod or the vertical upright is fastened by a fastener; the height-width ratio of the formwork support is 2.71 while the height of the formwork support is 8.15m; and the pace of the vertical upright is 0.9m and the longitudinal spacing of the vertical upright is 0.65m while the horizontal spacing thereof is 0.6m. Steel pipes with a diameter of 48 multiplied by 3.5 are used for setting up the formwork support and the joints are connected with a fastener respectively. The upper part of the formwork support supports the double steel pipes with a diameter of 48 multiplied by 3.5 by an adjustable bracket to be used as main beams for supporting formworks. The bottom of the adjustable bracket is inserted into the vertical upright of the formwork support for fixing and the distance from the upper surface of the adjustable bracket to the upper surface of the topmost transverse pipe of the support is 0.55m and the section of the adjustable bracket, extending out of the vertical upright, is 0.32m and adjusted within 0.32m. The buckled type steel pipe scaffold formwork support has safe and stable structure and convenient assembly and disassembly.

Owner:杭州二建建设集团有限公司

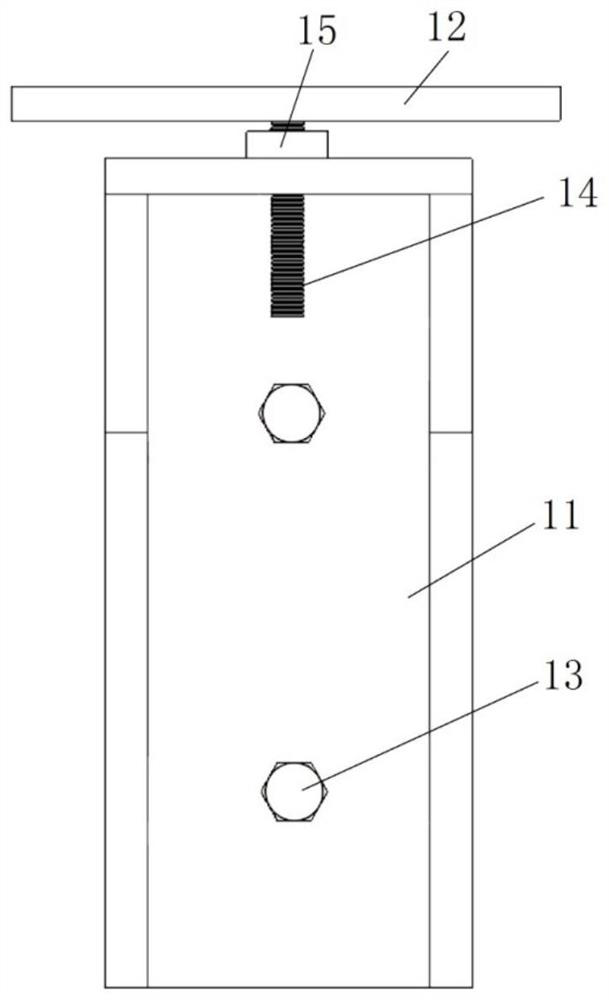

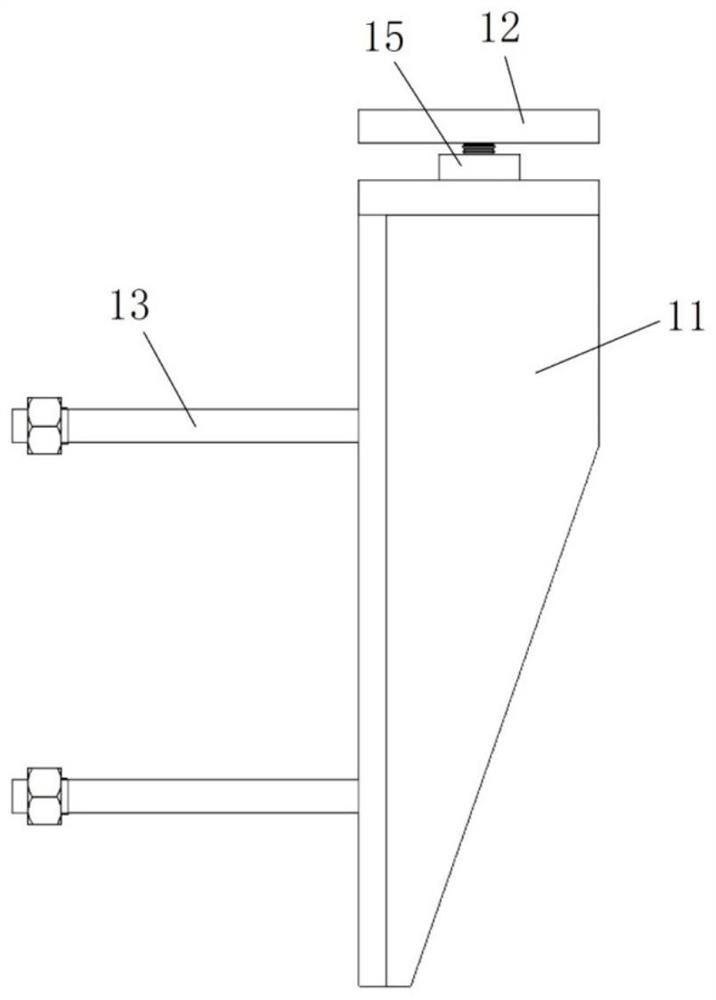

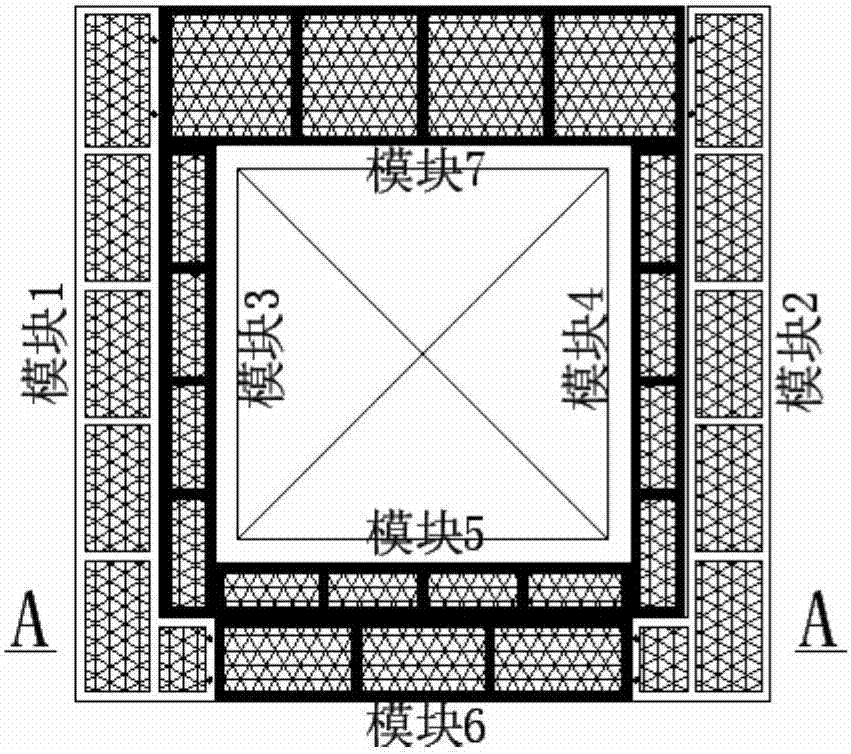

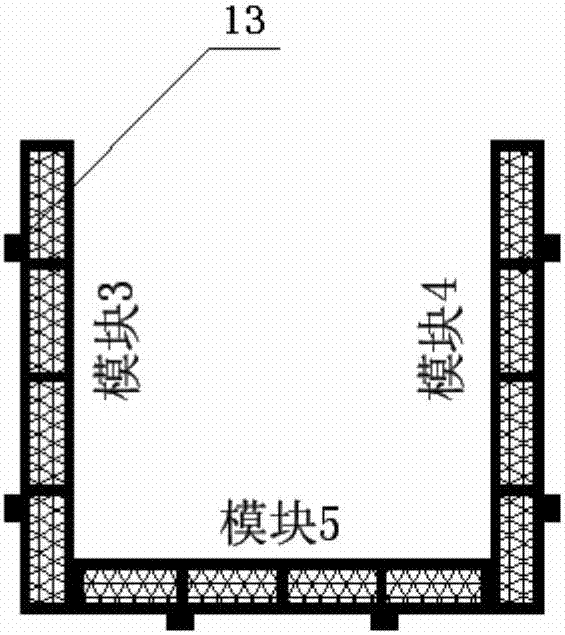

Adjustable limiting device for joist

PendingCN113006370AIncrease spacingSimple structureGirdersJoistsJoistElectrical and Electronics engineering

The invention discloses an adjustable limiting device for a joist, and belongs to the technical field of support frame auxiliary equipment. The adjustable limiting device comprises two steel channels and a plurality of adjusting assemblies, wherein the two steel channels are oppositely arranged, each adjusting assembly is arranged between the two steel channels, and both ends of each adjusting assembly are respectively connected with the two steel channels. According to the adjustable limiting device, the clear distance between the steel channels can be changed by adjusting the adjusting assemblies, so that the universality of joists of the 48 system and the 60 system is achieved, the two steel channels are detachably assembled, can be conveniently disassembled as required and can be repeatedly used, and the generalization performance is high.

Owner:SHANGHAI HONGJIN EQUIP & ENG CO LTD

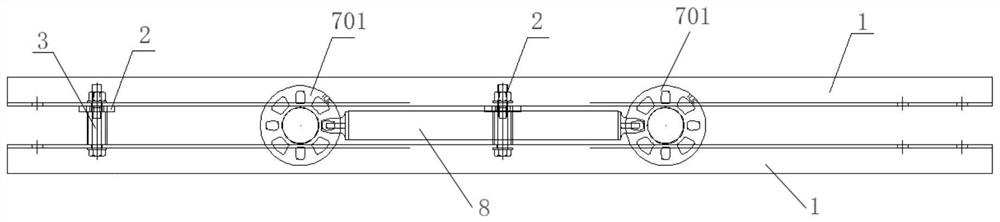

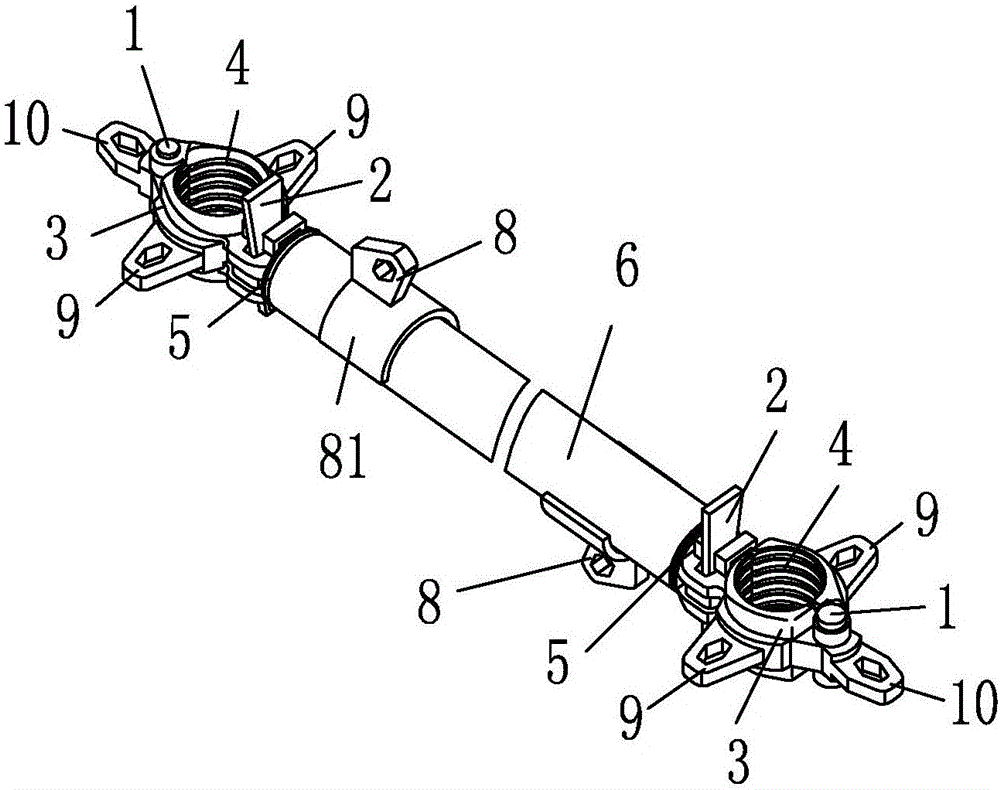

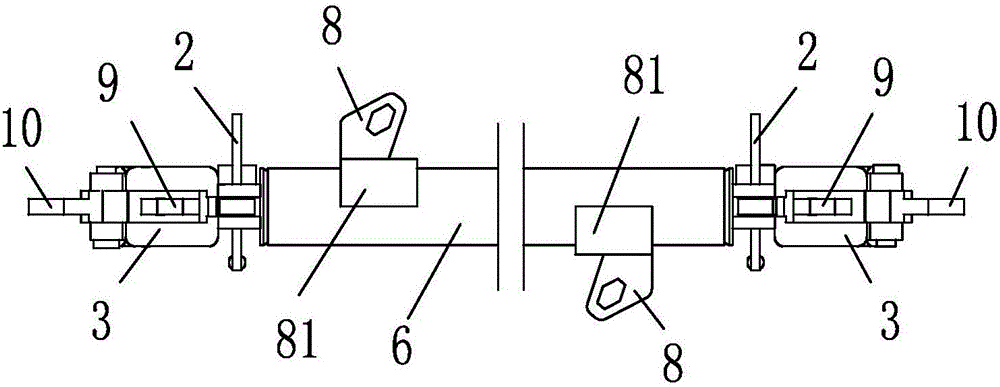

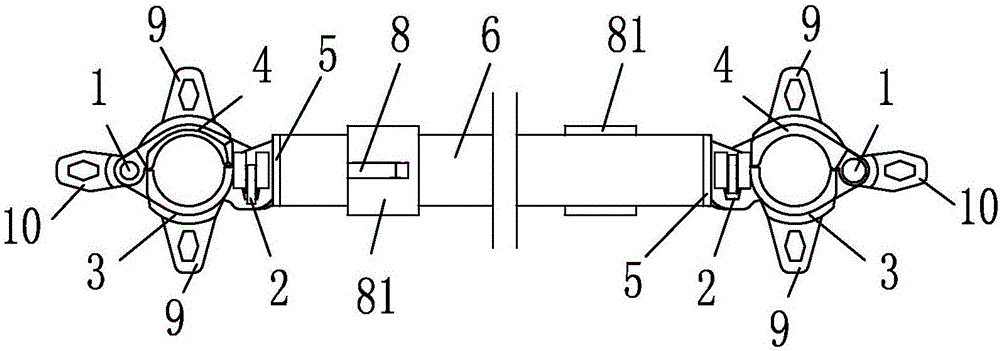

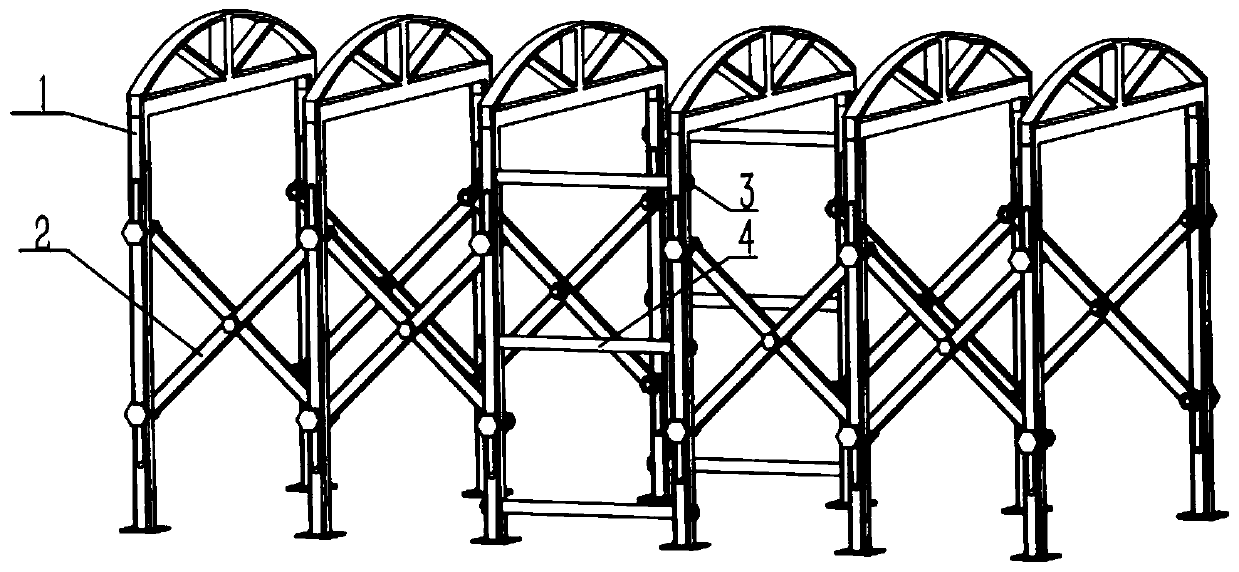

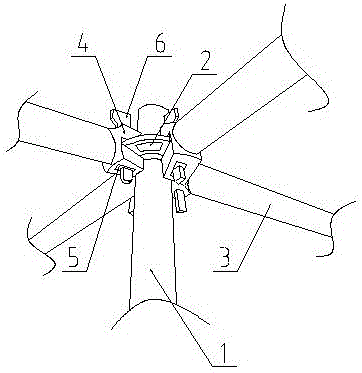

Multi-interface transverse pull rod, simple transverse pull rod, slant bracing rod and tower frame

The invention discloses a multi-interface transverse pull rod, a simple transverse pull rod, a slant bracing rod and a tower frame. The multi-interface transverse pull rod comprises a tubular pull rod body and wedge-shaped locking fasteners at the two ends of the body, and each fastener is provided with a first expanding interface; slant bracing interfaces are arranged on the pipe walls of the two ends of the tubular pull rod body respectively, and the two slant bracing interfaces are staggered at 180 degrees; the simple transverse pull body comprises a tubular pull rod body and pull rod connectors at the two ends of the tubular pull rod body, and the pull rod connectors and the first expanding interfaces in the multi-interface transverse pull rod form a slant wedge locking structure; the pipe walls of the two ends of the tubular pull rod body are provided with slant bracing interfaces respectively; the slant bracing rod comprises a slant bracing rod body and pull rod connectors arranged at the two ends of the slant bracing rod body, the pull rod connectors and the slant bracing interfaces in the multi-interface transverse pull rod or the simple transverse pull body form a slant wedge locking match; the tower frame is formed by erecting a stand pipe, the multi-interface transverse pull rod, the simple transverse pull rod and the slant bracing rod. The multi-interface transverse pull rod, the simple transverse pull rod, the slant bracing rod and the tower frame have the advantages that slant wedge locking structures are all adopted in the fasteners and the expanding interfaces, the tower frame is convenient to put up and dismantle and firm in locking, the quantity of the fasteners is small, and the efficiency in putting up and dismantling is high.

Owner:泰博新型建筑科技(苏州)有限公司

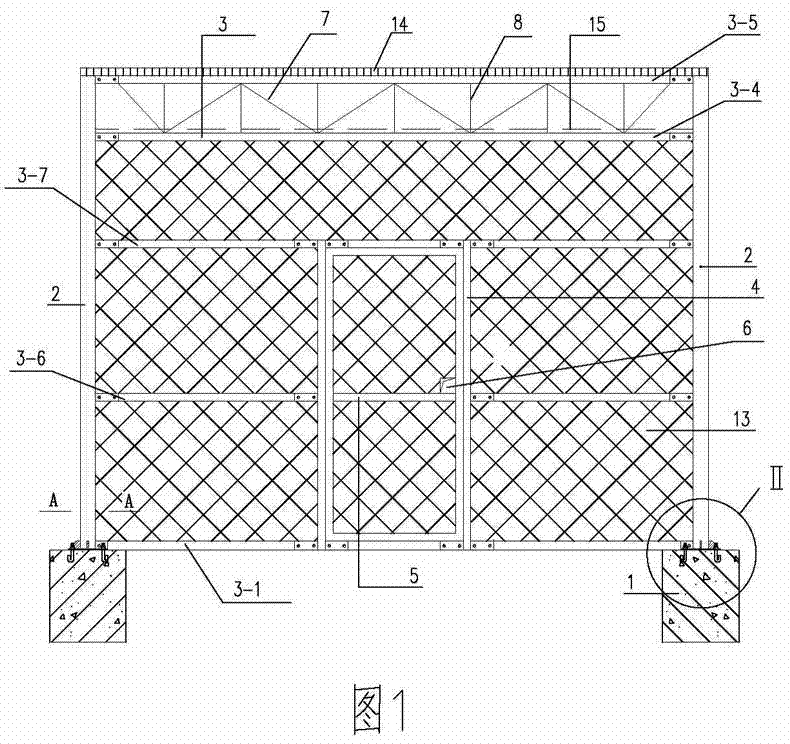

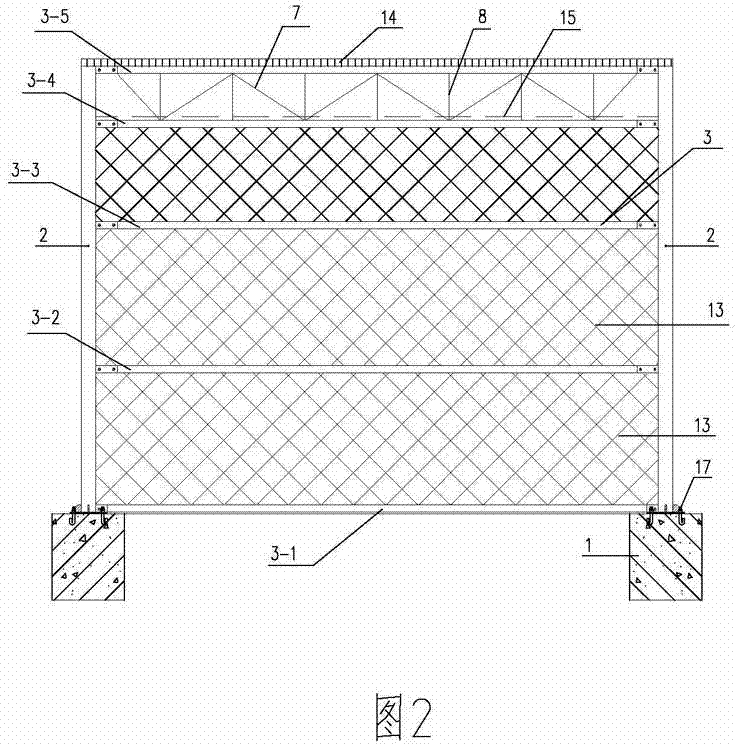

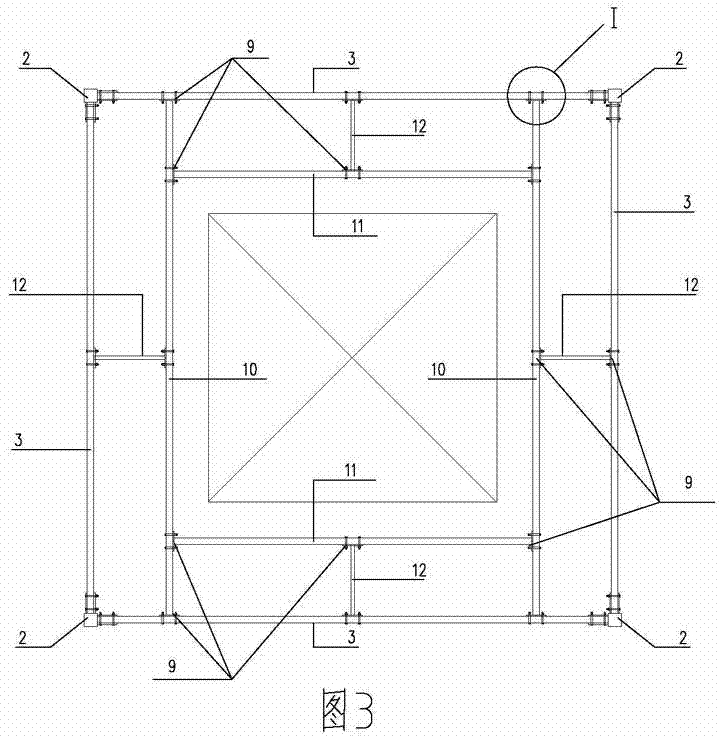

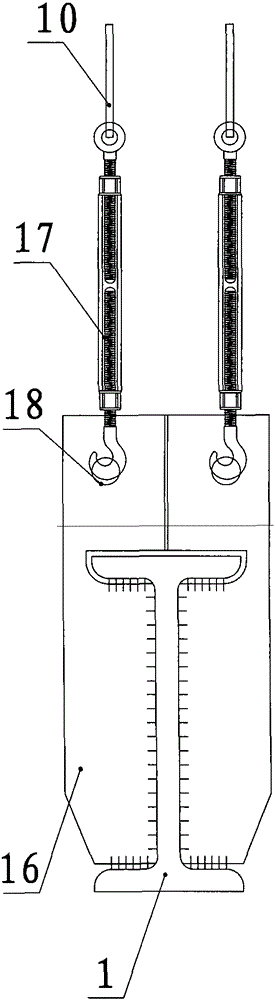

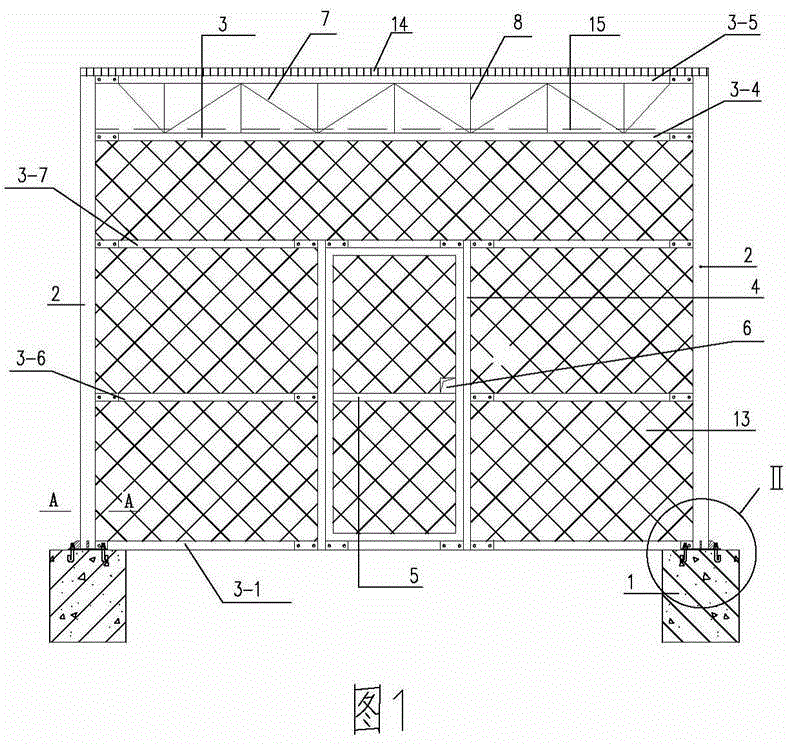

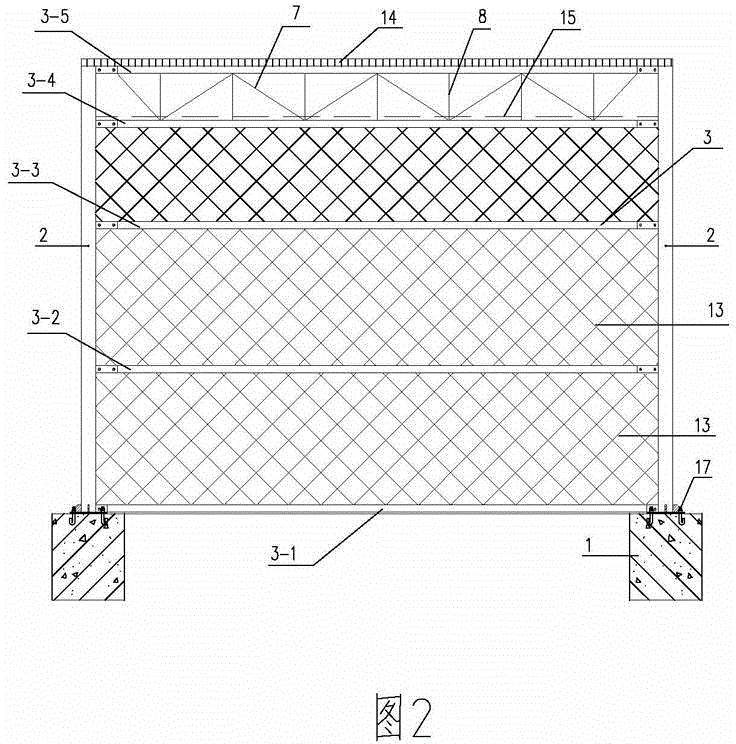

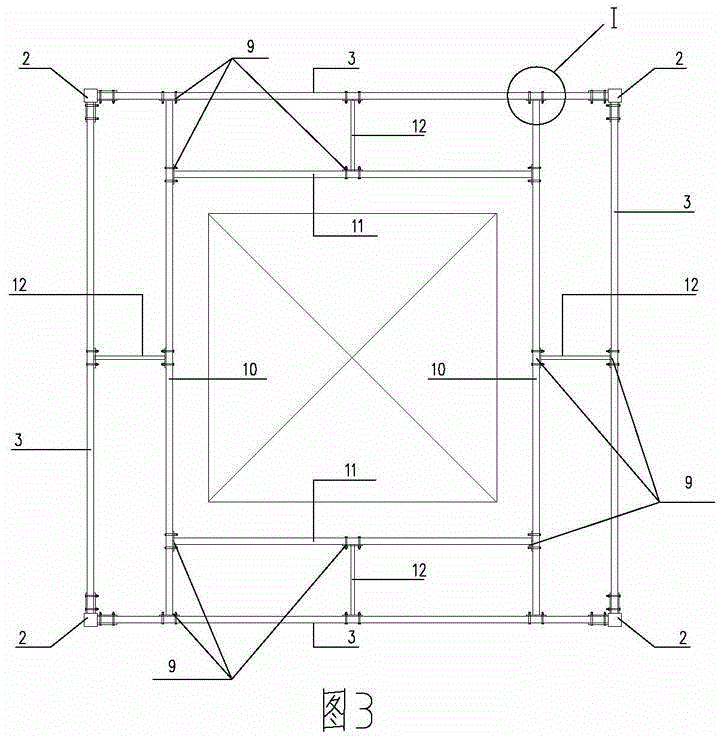

Reusable anti-climbing device at bottom layer of tower crane on building construction site

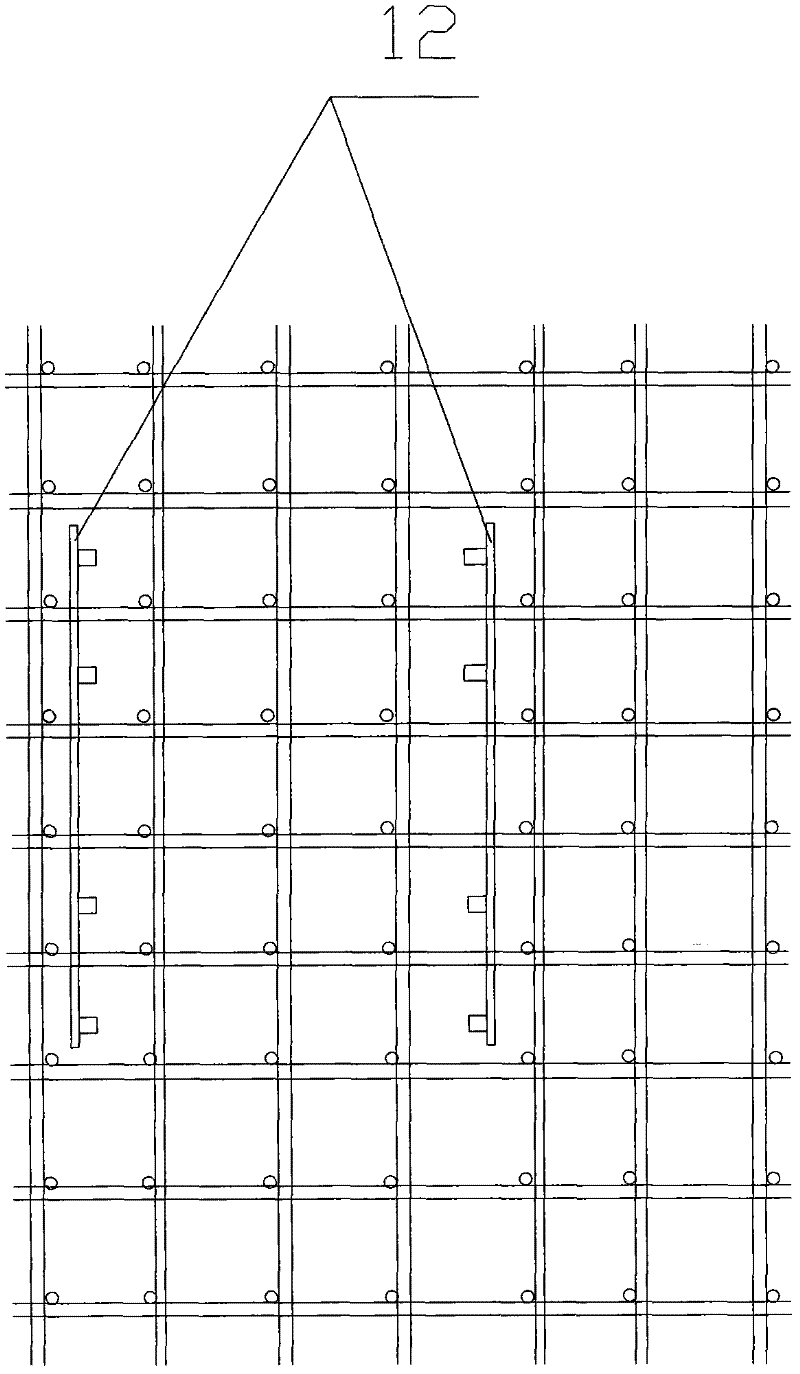

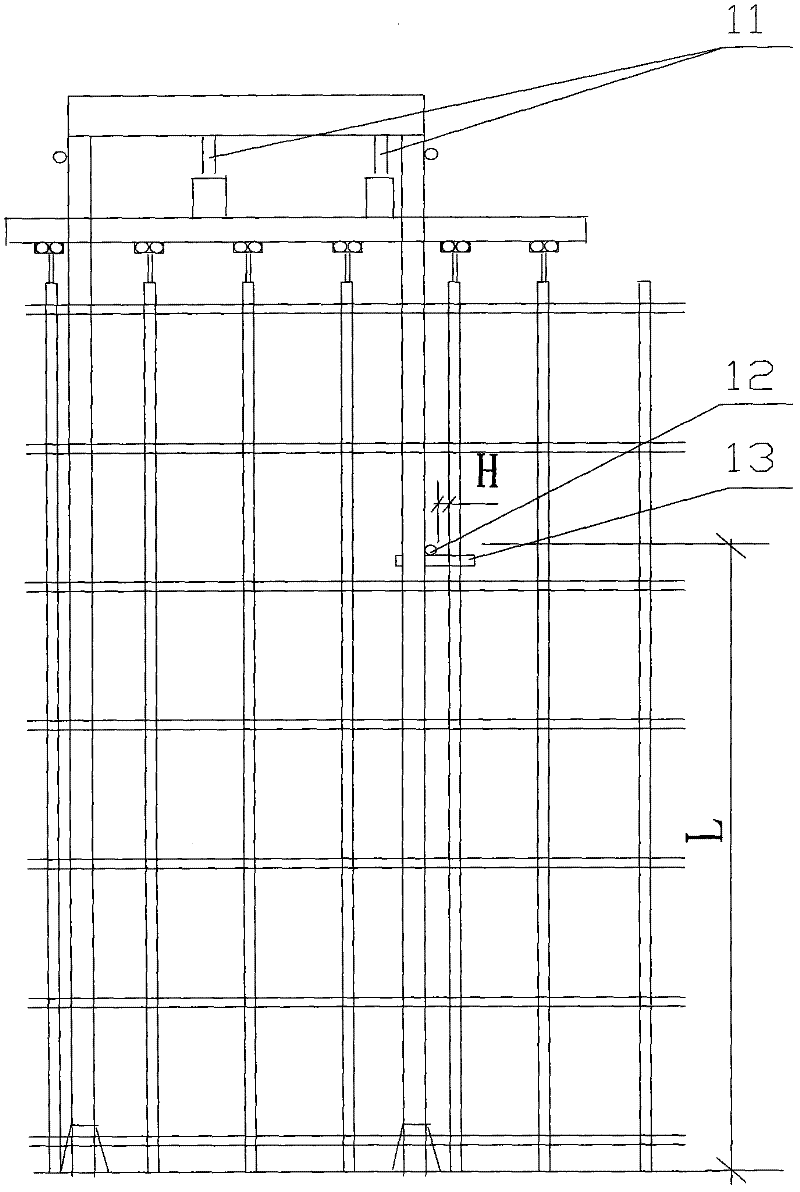

ActiveCN102900238AEasy to build and disassembleIn line with the concept of green constructionBuilding material handlingEngineeringTower crane

The invention relates to a reusable anti-climbing device at the bottom layer of a tower crane on a building construction site. The reusable anti-climbing device is formed by a steel structure framework; and the steel structure frame is composed of stand columns, truss girders, structural cross beams, a door frame, a door, inclined braces, upright poles, connecting pieces, long auxiliary beams, short auxiliary beams and short beams which are connected and combined through bolts and are respectively standard parts with unified specification. The stand columns are connected to four square ground foundations; and the door with a door lock is arranged in the front of the steel structure framework, a reinforcing mesh is laid at the periphery of the steel structure framework, an anti-falling scaffold board is laid on the roof of the upper layer of the steel structure framework, and a color steel plate is laid on the roof of the lower layer of the steel structure framework. The reusable anti-climbing device at the bottom layer of the tower crane on the building construction site is formed by combining the multiple standard parts which are designed according to conditions such as the sizes of standard knots of the tower crane and design codes for lightweight steel structures. The reusable anti-climbing device has the characteristics of being suitable for the sizes of the standard knots at the bottom layers of different tower cranes, capable of being freely combined, convenient, practical and low in cost, and saving labor and time. The reusable anti-climbing device is convenient to dismantle, is in line with a green construction idea and is safe to use on the site.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

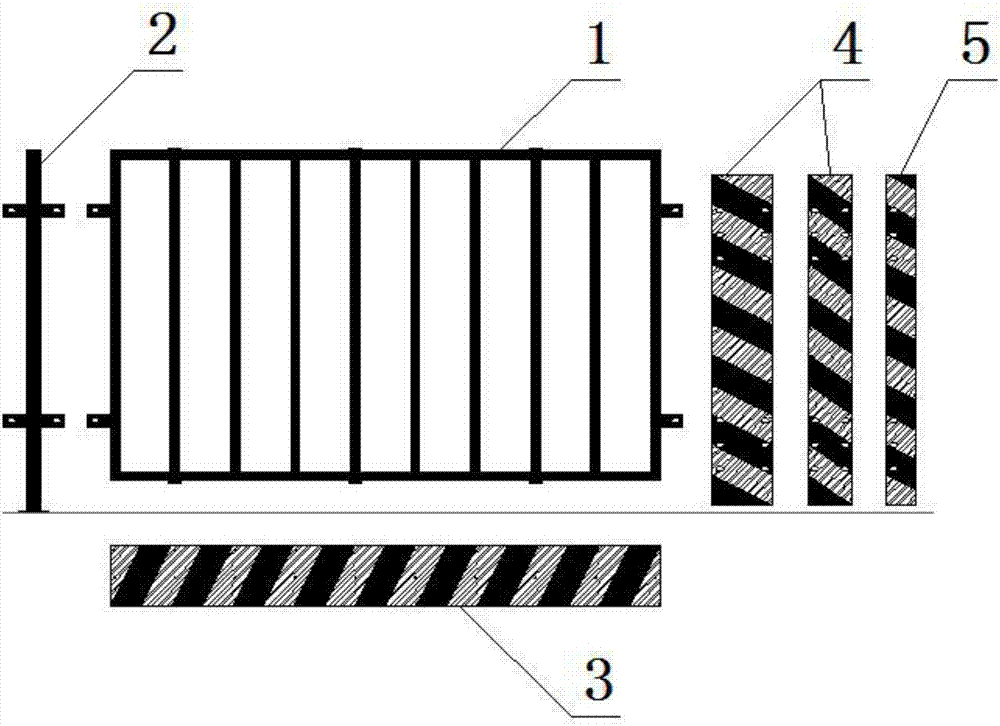

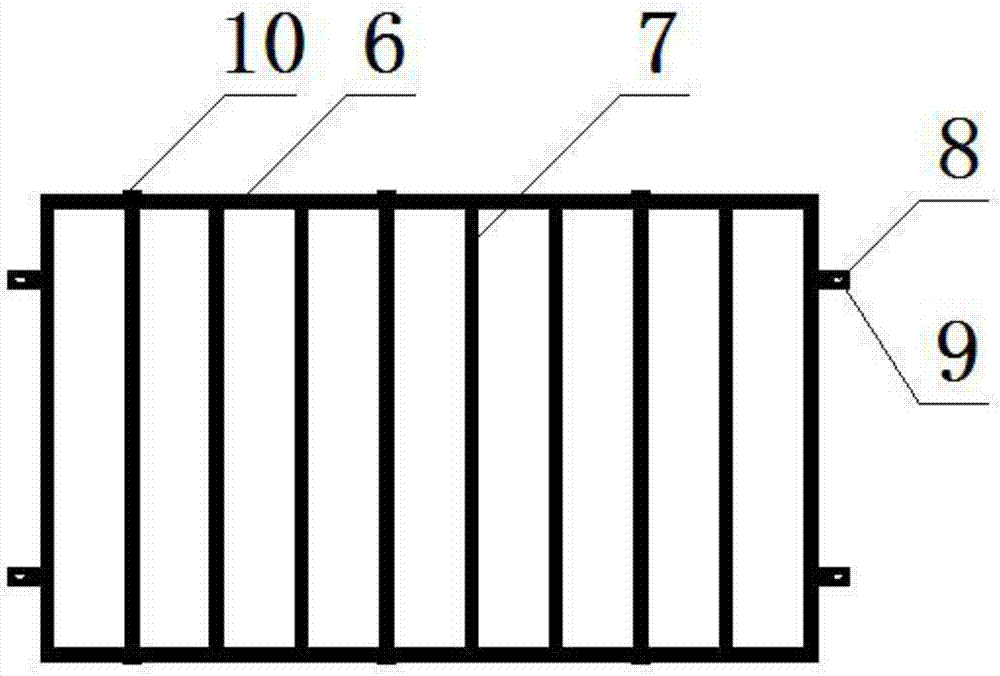

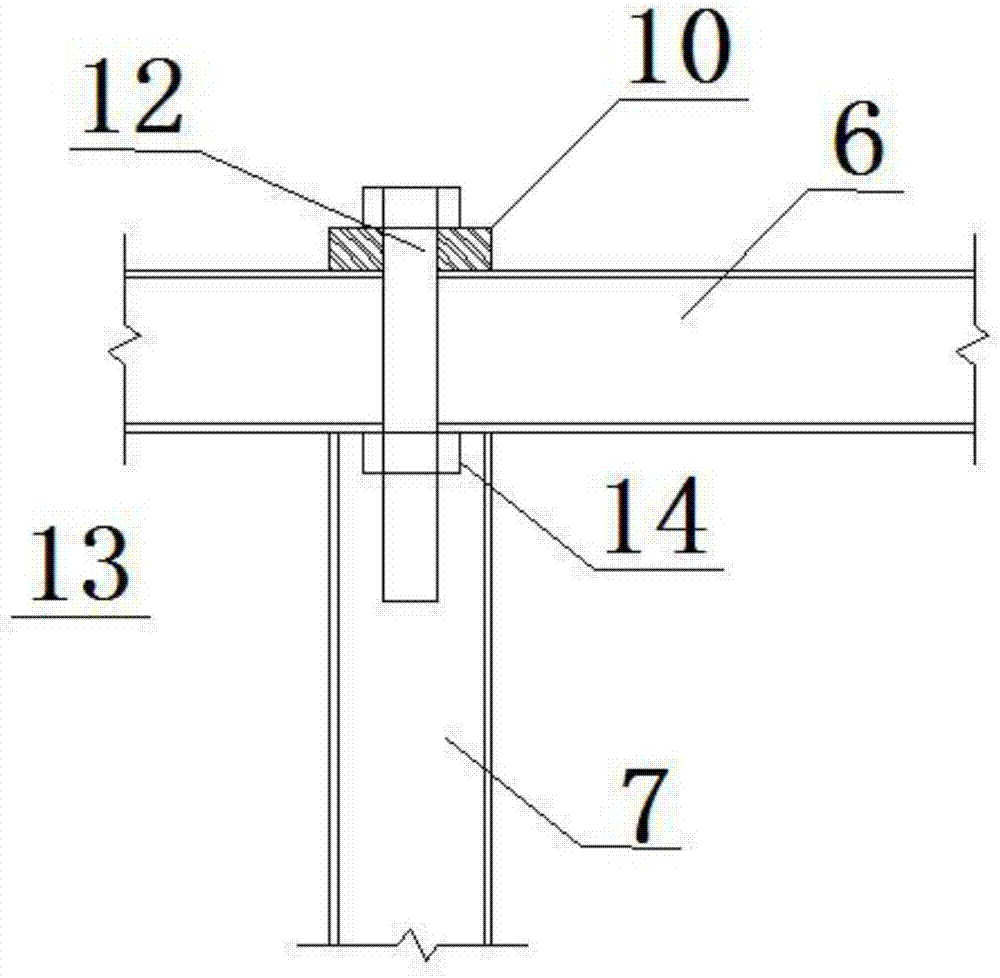

Shaping composite steel structure safety protection part and construction method thereof

InactiveCN107476591AVarious combinationsImprove general performanceBuilding material handlingSteel squareBuilding construction

The invention discloses a shaping composite steel structure safety protection part and a construction method thereof. The shaping composite steel structure safety protection part comprises a grille, a stand column, a baffle, a modulus baffle and a corner plate. The vertical face of the grille is rectangular, and the grille is constituted by evenly arranging an upper cross rod, a lower cross rod and a plurality of vertical rods; the stand column is constituted by a steel square pipe, a fixing plate, a base, a waterproof sealing plate and expansion foundation bolts; the vertical face of the baffle is rectangular and is made of a steel plate with the thickness being 2 mm; and the corner plate adopts the modulus baffle and is formed by bending along the vertical central axis of the modulus baffle, the plane is in an L shape, and the left vertical face and the lower vertical face are both rectangular; the vertical face of the modulus baffle is rectangular, and the rectangular height keeps consistent with the grille height. According to the shaping composite steel structure safety protection part and the construction method thereof, shaping composite design is adopted, the composite forms are diversified, the universality is high, setting up and dismantling are convenient, protection is safe and reliable, the turnover using rate is high, and the construction cost is effectively reduced.

Owner:CHINA MCC17 GRP

A construction method for the whole-span bridge demolition system based on ground support

ActiveCN104727236BSmooth downUniform lowering speedBuilding repairsBridge strengtheningBuilding constructionGround support

The invention relates to the field of bridge dismounting, in particular to a whole striding bridge lowering dismounting system based on ground supporting and a construction method thereof. The system comprises at least two sets of supporting structures used for supporting a lowering box beam. Each supporting structure comprises a main beam and two supporting frames located at the two ends of the main beam, wherein the two ends of the main beam are fixed to the main supporting frames, the main beam is arranged in the transverse direction, a lowering power system is arranged at the upper end of the main beam and connected with a sling, and a pocket hoisting device used for hoisting the lowering box beam is arranged at the lower end of the sling. The system is simple in structure, convenient to operate and high in construction safety, environmental friendliness is achieved, energy is saved, and extremely high popularization value is achieved.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

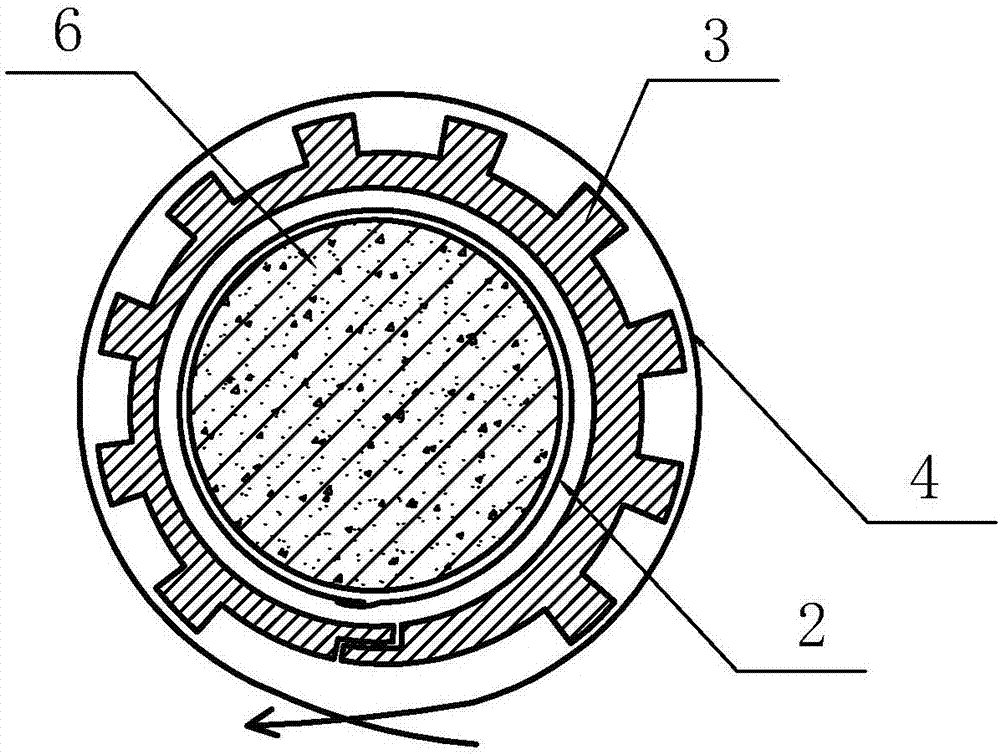

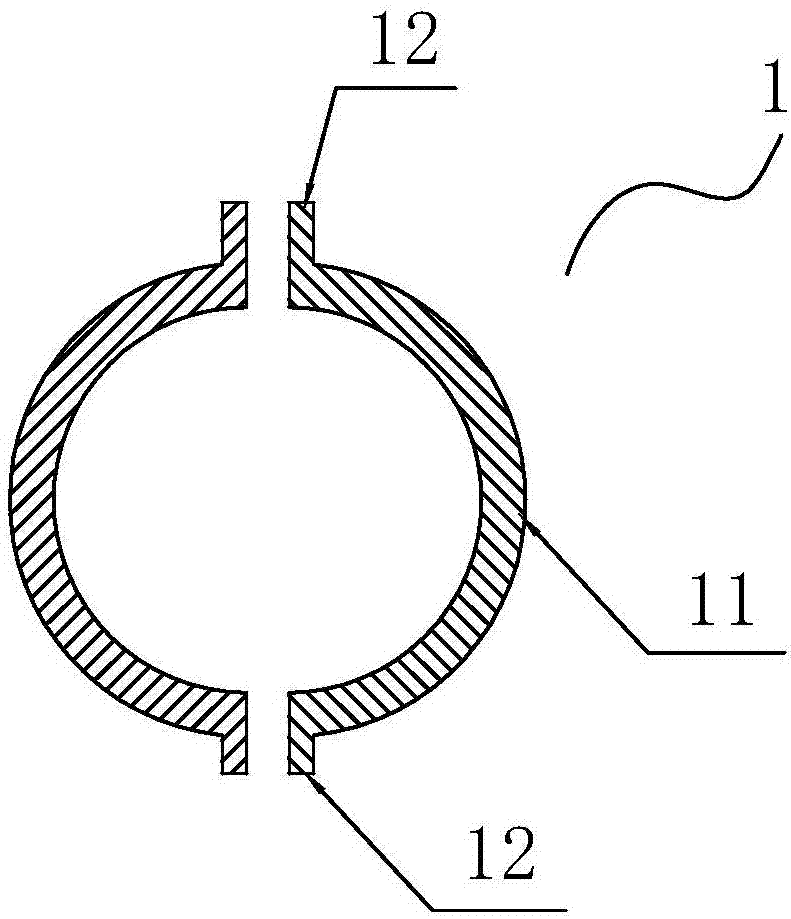

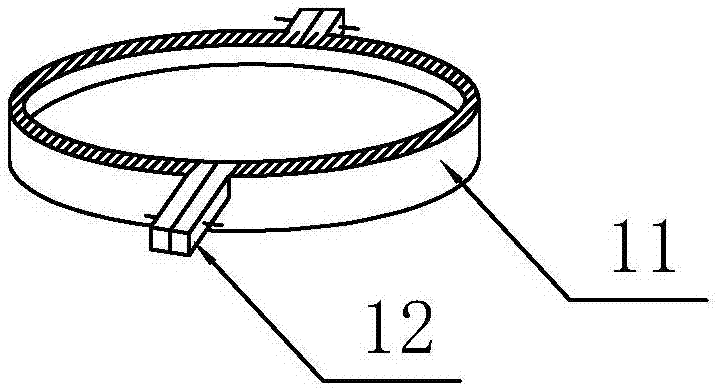

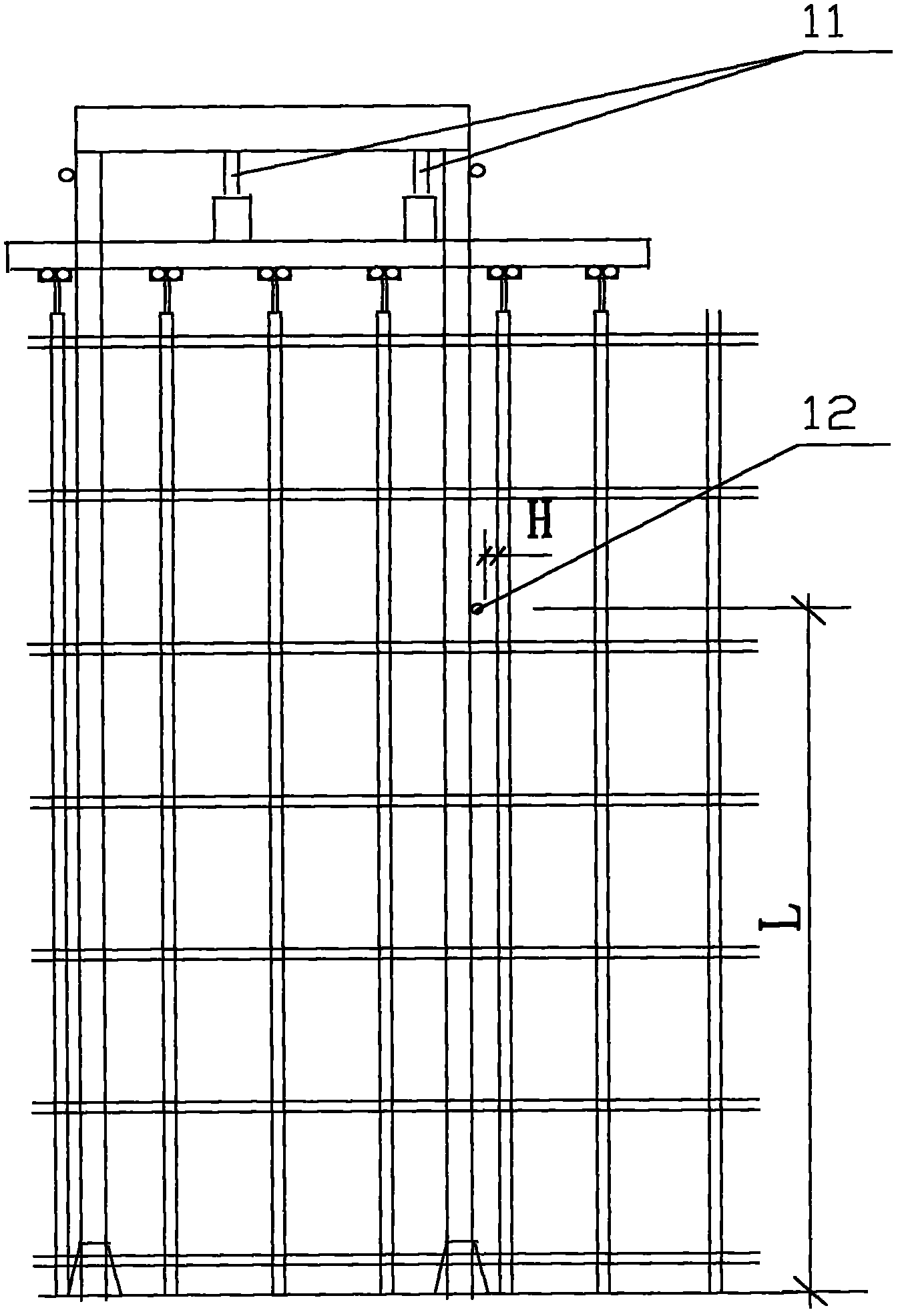

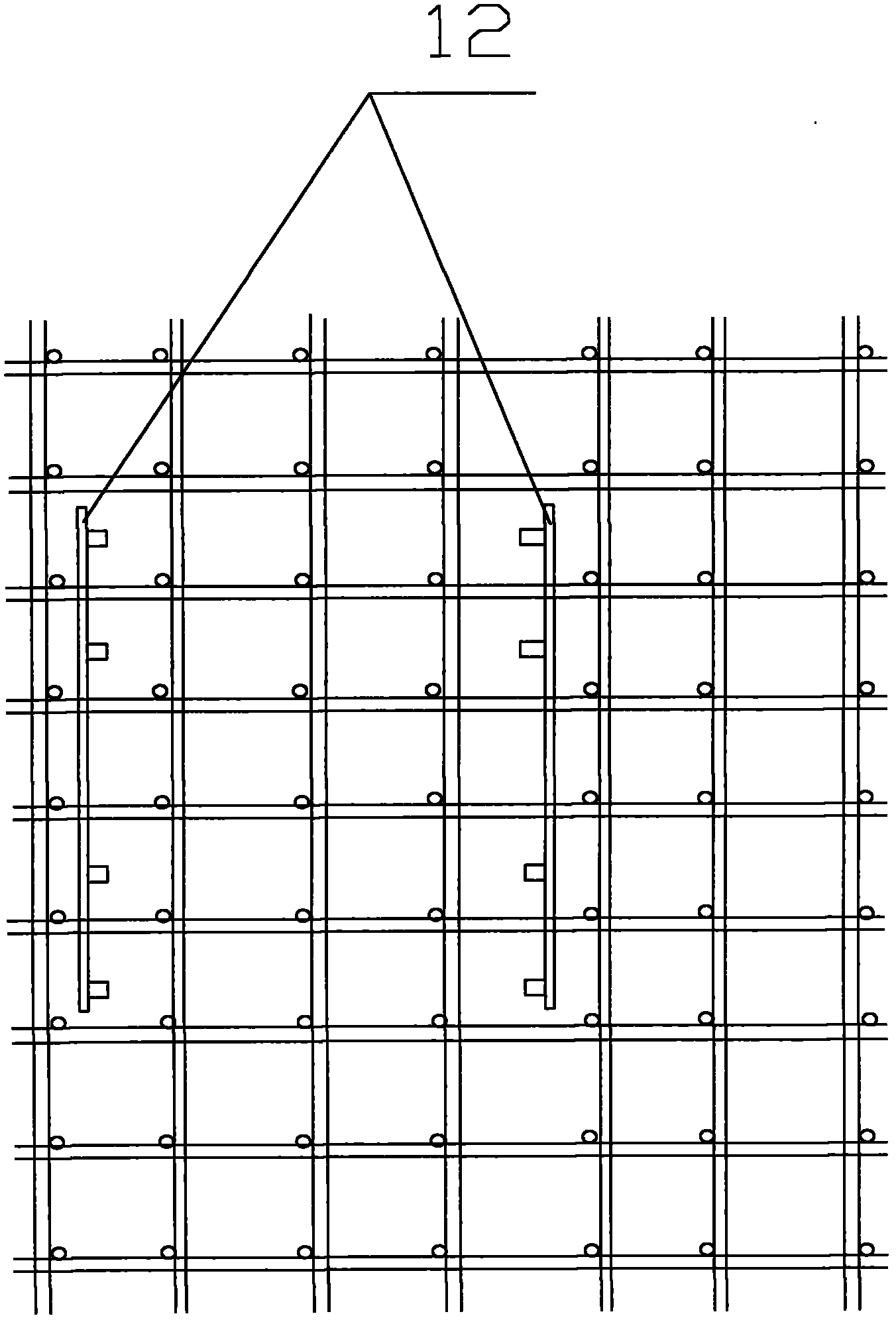

Concrete cylindrical formwork system

PendingCN107366424AImprove deformation resistanceSimple structureForms/shuttering/falseworksArchitectural engineeringPolyvinyl chloride

Provided is a concrete cylindrical formwork system. The concrete cylindrical formwork system comprises an inner lining round frame, an inner lining plate, an outer formwork and an outer hoop; the inner lining round frame comprises two semicircular rings which are butt-jointed; connecting plates are correspondingly arranged on the upper parts of the two ends of the semicircular rings and are protruded out of the outer sides of the semicircular rings, and bolt holes are formed in the connecting plates; the inner lining plate is an arbitrarily bended thin plate made of a polyvinyl chloride material and is adapted to the size of the concrete cylindrical circumference; the outer formwork is a plastic plate which is adapted to circumference size of the inner lining plate, the inner side of a section of the outer formwork is a smooth face, and the outer side of the section of the outer formwork is provided with vertical rib strips; the outer hoop is a fastening plastic strip with holes formed in one end and sharp corners and teeth arranged on the other end; and the inner lining round frame is placed on the upper end of an inner cylindrical formwork formed by the inner lining plate, the inner cylindrical formwork is wrapped with the outer formwork, and the inner lining plate and the outer formwork are fixed by the outer hoop. According to the concrete cylindrical formwork system, the construction efficiency is improved, using turnover times are increased, and construction cost is reduced.

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

Method for increasing horizontal restraint and improving and determining bearing capacity of supporting frame

InactiveCN102182310ASimple structureImprove bearing capacityBuilding material handlingScaffold accessoriesFastenerBearing capacity

The invention relates to a method for increasing horizontal restraint and improving and determining the bearing capacity of a supporting frame. The supporting frame moves eight strides in longitudinal direction, moves six strides in transverse direction and is loaded within a 5-stride*5-stride range; the supporting frame moves two strides to one side in the longitudinal direction outside a loading area and moves one stride to the other side; the supporting frame moves one stride to one side in the transverse direction outside the loading area and moves no stride to the other side; the height of the supporting frame is 8.2 metres (m); step distances of vertical rods are 1.24 m; longitudinal intervals of the vertical rods are 0.9 m; transverse intervals of the vertical rods are 0.9 m; the ratio of height to width of the supporting frame is 1.5; the supporting frame is constructed by steel pipes with the diameter of Phi 48*3.2; an adjustable bracket which supports double steel pipes with the diameter of Phi 48*3.2 serves as a supporting load girder at the upper part of the supporting frame; the bottom of the adjustable bracket is inserted into the vertical rods of the supporting frame for fixation; a distance between an upper surface of the adjustable bracket and the upper surface of the uppermost transverse pipe of the supporting frame is 0.55 m; the adjustable bracket extends out of the vertical rods by 0.3 m; and a horizontal restraint rod is arranged on a counter-force frame at a position which is 5.3 m high. The structure of the supporting frame of a fastener can be economical, reasonable, safe and applicable by increasing the horizontal restraint and improving and determining the bearing capacity of the supporting frame.

Owner:ZHEJIANG DAHUA CONSTR GROUP

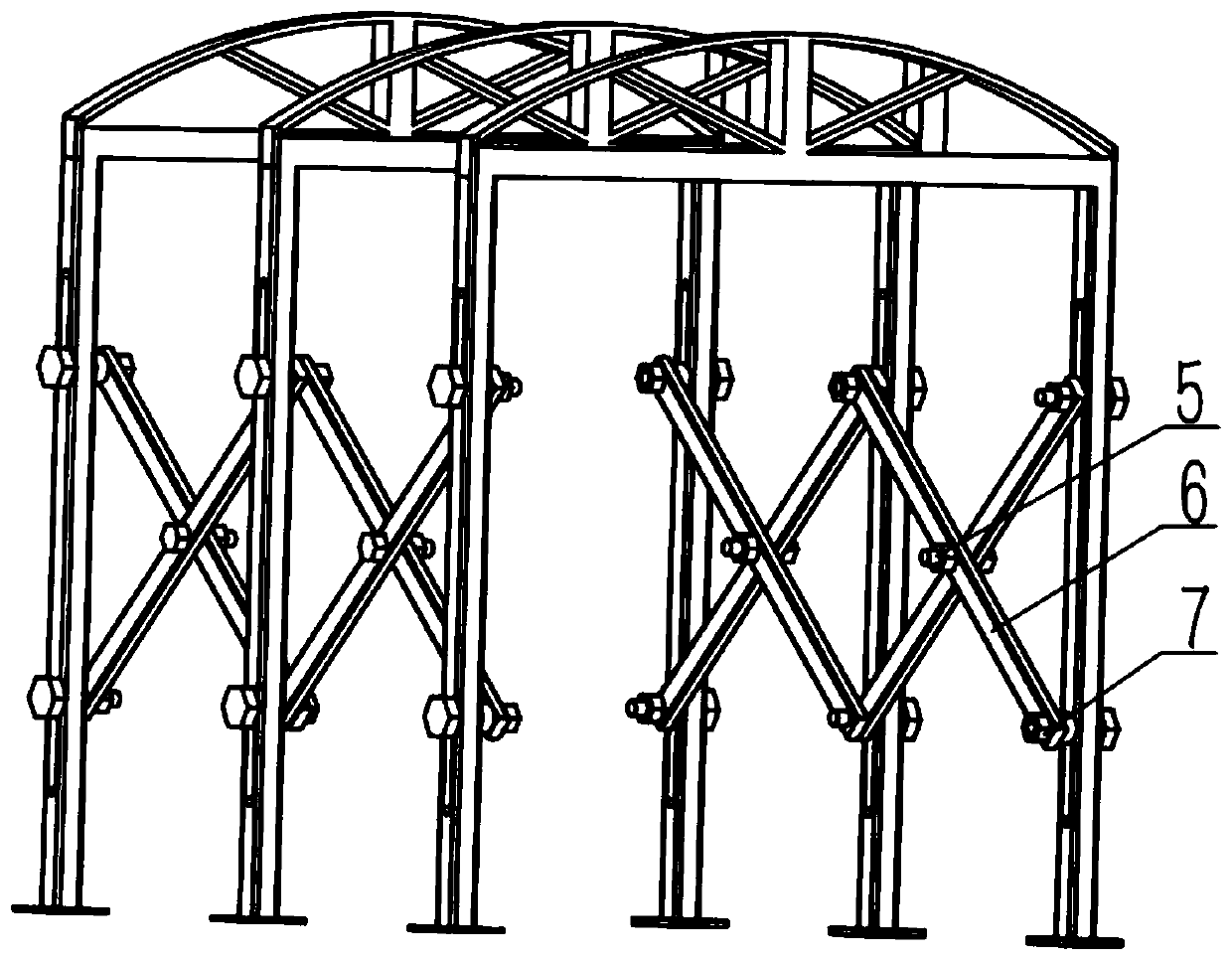

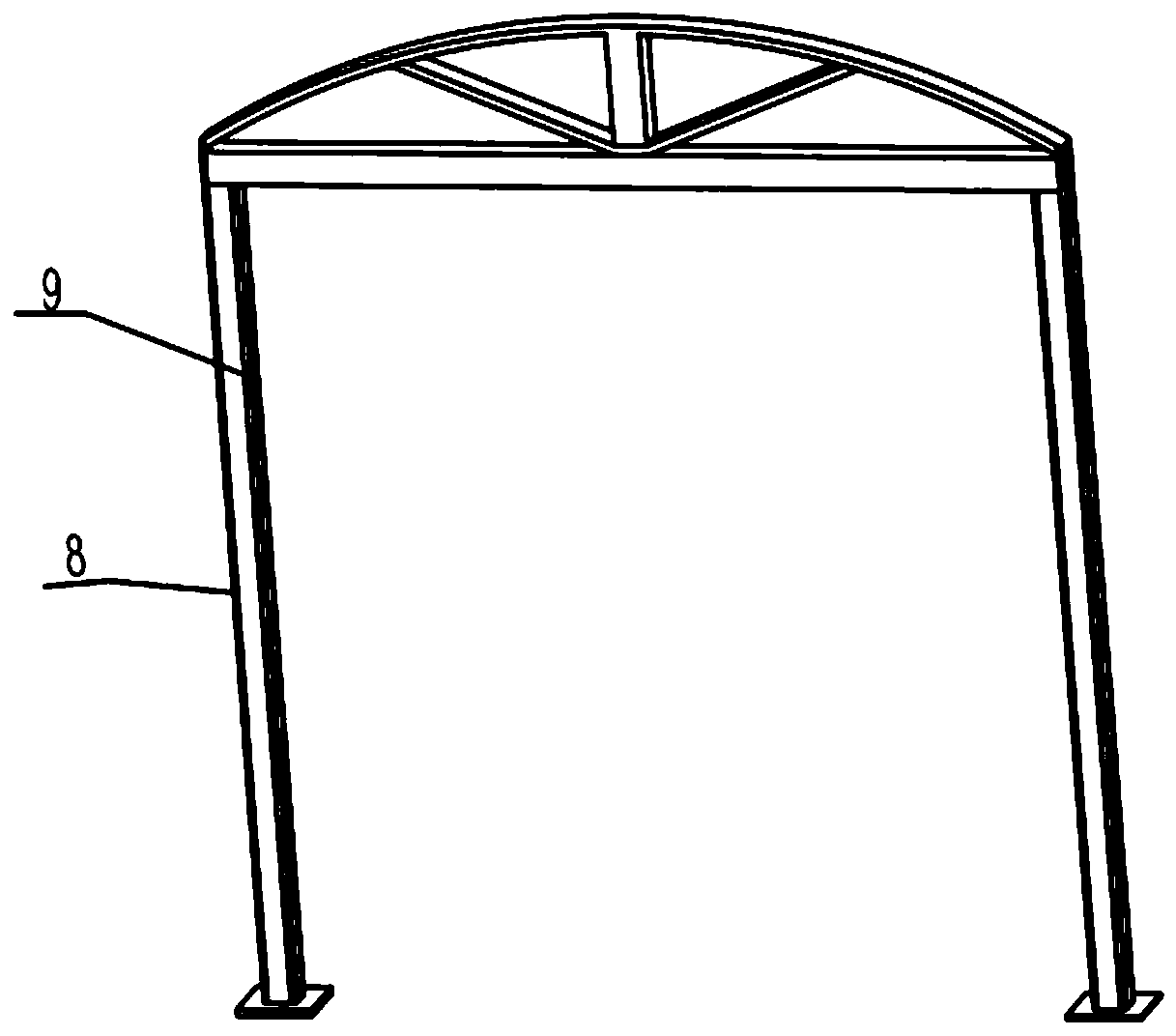

Telescopic tent capable of expanding infinitely

PendingCN111119568AEasy to build and disassembleEasy telescoping controlTents/canopiesMechanical engineeringParallelogram

The invention discloses a telescopic tent capable of expanding infinitely and relates to the technical field of tents. The tent comprises a plurality of inverted U-shaped supports which are linearly arranged, and a connecting fixing piece is arranged between two adjacent supports. According to the invention, the two adjacent door-type supports are connected through a cross rod, the cross rod is composed of two straight rods, the two straight rods are connected through hinged fixing bolts at a middle part, and the two ends of the straight rods are connected with the supports through connectingfixing bolts, so that the cross rod and the two door-type supports form a deformable parallelogram, and the purposes of convenient construction and disassembly, convenient telescopic control and infinite expansion are realized; by connecting two adjacent door-shaped supports on the connecting rods, the purposes of convenient construction and disassembly and convenient telescopic control are realized; and the adjacent three door-shaped supports are connected through the cross rod to form a simple telescopic tent, and then the adjacent two simple telescopic tents are connected through the connecting rods to realize the purposes of convenient construction and disassembly, convenient telescopic control and infinite expansion.

Owner:HANGZHOU KAIDA ELECTRIC POWER CONSTR +2

Installation method of umbrella-shaped roof structure

ActiveCN113404199AShorten the construction periodImprove construction accuracyBuilding roofsStructural deformationSpatial structure

The invention provides an installation method of an umbrella-shaped roof structure, aims at solving the technical problems that an existing installation construction method is inconvenient due to the fact that the umbrella-shaped roof structure is complex in shape, large in component number, large in high-altitude splicing difficulty and high in precision requirement, and relates to the technical field of construction of large space structures of constructional engineering. An umbrella-shaped roof is divided into 20-30 umbrella-shaped unit structures, the adjacent umbrella-shaped unit structures are connected into a whole through long-strip-shaped wave-shaped roof steel beams, and the installation method comprises the following steps of (1) performing modular assembly on the ground; (2) installing a temporary support; (3) performing hoisting in units; and (4) dismantling the temporary support and monitoring structural deformation: unloading a sandbox support, dismantling the temporary support and monitoring the structural deformation. According to the installation method, the construction period is effectively shortened, the construction precision is improved, and meanwhile the installation quality of other related structures attached to the umbrella-shaped roof structure is improved.

Owner:CHINA RAILWAY CONSTR ENG GROUP

Deck walkway rack building method

InactiveCN106256681AEnsure heightMake sure the widthDry-dockingSlipwaysArchitectural engineeringUltimate tensile strength

The invention relates to a deck walkway rack building method. The method comprises the following steps: a batch of vertical rods and cross rods are produced, wherein the length of the vertical rod is 2.1 m, and the length of the cross rod is 1.1 m; the vertical rods are arranged as multiple rows with left and right parallel, a fixed ring is welded at upper part of each vertical rod, two adjacent vertical rods (including left and right as well as back and forth vertical rods) are connected through the cross rod, the head restraints are arranged at two ends of the cross rod, the head restraint is clamped on the fixed ring, a fixed jack is arranged on the head restraint, a latch is arranged in the fixed jack through interpolation, and the head restraint of the cross rod is fixedly connected with the fixed ring through the latch. The method cancels a mode by using a traditional fastener for connection, and employing a plug-in mode, so that the building is more convenient, the steel pipe joint points are hardly generate collision condition, labor amount is less, labor intensity is effectively reduced with certain degree, the building time is shortened, and the work efficiency is increased.

Owner:CHENGXI SHIPYARD

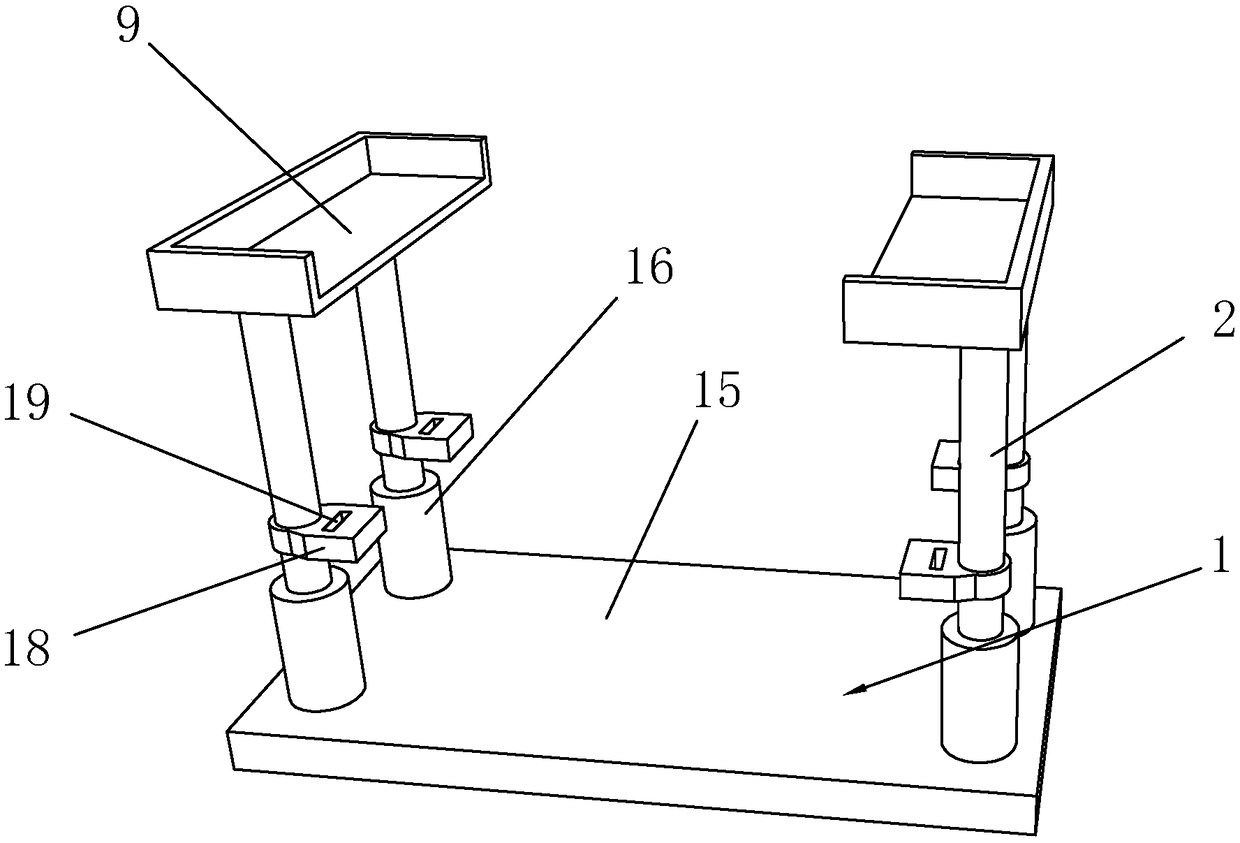

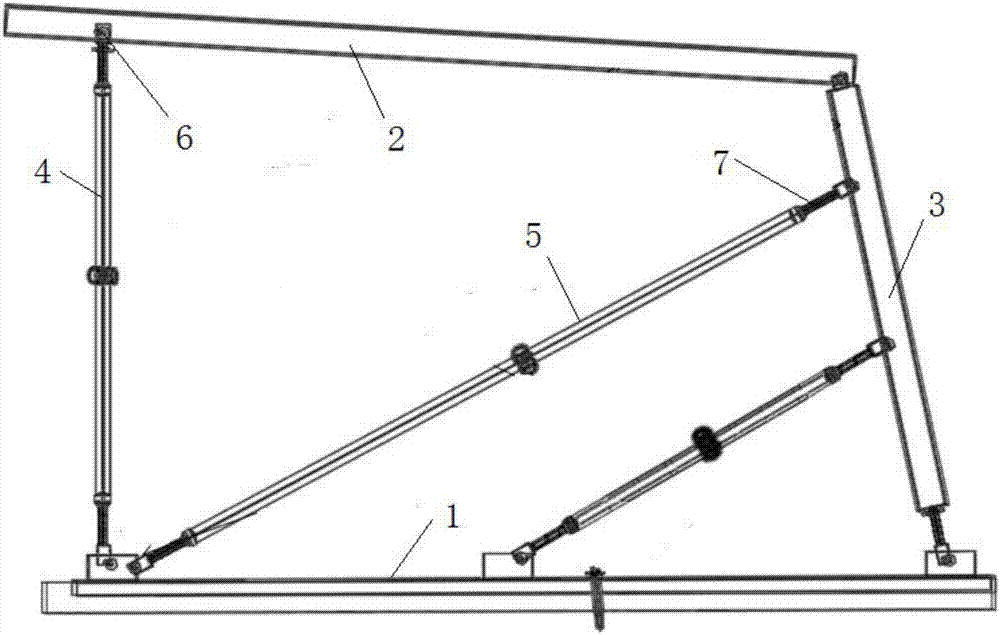

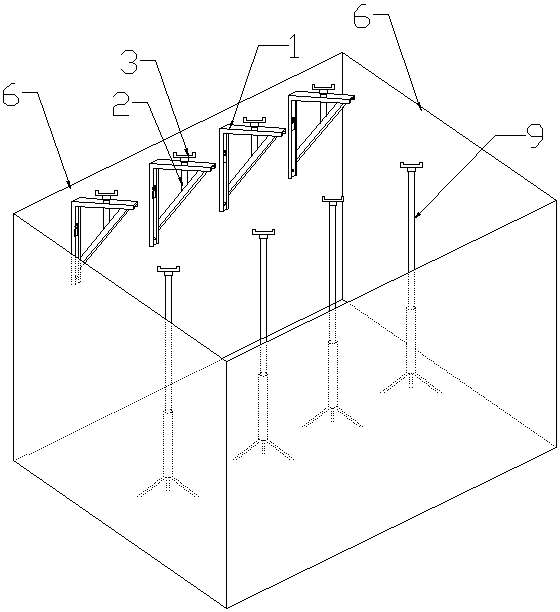

Adjustable tripod support system and method for fabricated concrete shear wall structure

ActiveCN105649325BStable supportSmall footprintForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemFalsework

The invention discloses an adjustable tripod supporting system and method of a fabricated concrete shear wall structure. Pre-embedded holes are preset in the two sides or the inner sides of the wall bodies; the pre-embedded holes are connected with tripods through opposite pulling or bolting of bolts; the tripods are mounted by utilizing the self stable structures of the wall bodies on the two sides; a row of independent supporting rods are erected in the middle of the wall bodies on the two sides for auxiliary supporting to form the complete and stable supporting system, so that the stable supporting on laminated slabs can be realized, and the supporting system can be widely applied to the engineering of the fabricated concrete shear wall structure. According to the supporting system, the structure is simple, the assembly and disassembly are simple and convenient, and the labor cost can be reduced; the manufacture cost is low, repetitive use can be realized, scaffold supporting is completely replaced, and the use cost is reduced; by utilization of the movable connection of brackets and sleeve, the adjustment is relatively precise; the occupied space of the lower part supporting is reduced, and the follow-up operation is facilitated; the used materials and tools are few, so that the assembly and the disassembly as well as the material and tool turnover by a tower crane are time-saving, and the construction period is shortened.

Owner:CCT TECH HENAN CO LTD +1

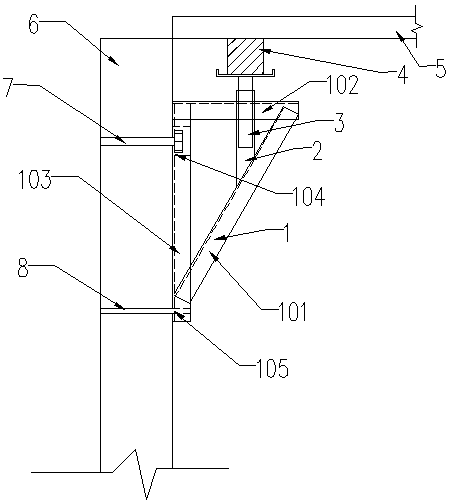

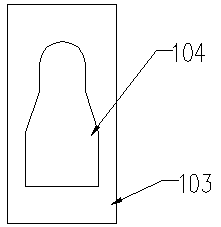

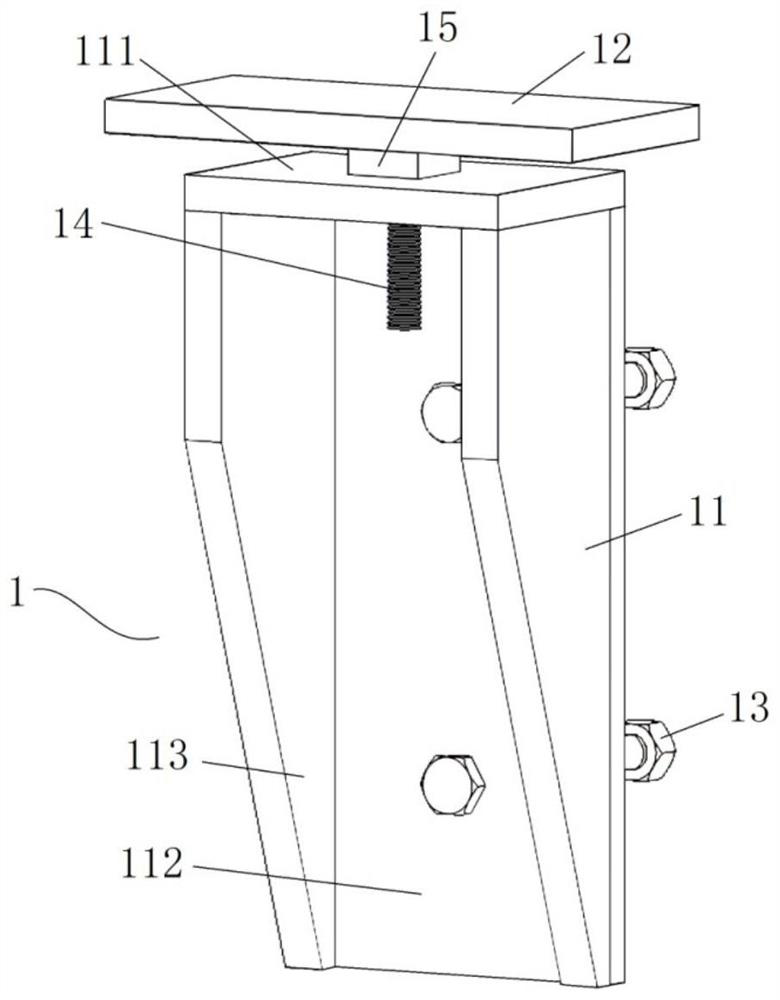

Fabricated building construction load self-bearing system and construction method thereof

The invention discloses an assembly type building construction load self-bearing system and a construction method thereof. The construction load self-bearing system comprises a prefabricated column, a prefabricated laminated beam, a prefabricated laminated plate and two kinds of corner connectors. Supporting corner connectors are installed on the side walls of the top of the prefabricated column through reserved through holes, the two ends of the prefabricated superposed beam are supported on supporting plates of the supporting corner connectors on the top of the column, the height of the prefabricated superposed beam is finely adjusted through adjusting bolts connected to the bottoms of the supporting plates, and triangular corner connectors are installed on the side walls of the prefabricated superposed beam through reserved spaced through holes. H-shaped steel channels are placed on the triangular corner connectors, the side edges of the prefabricated laminated slabs are supported on the H-shaped steel channels, and after the structural floor integral pouring layer is poured and tamped and maintained to the form stripping strength, all the corner connectors are dismantled. The prefabricated column is used as a main stress component of the main body structure, the stress system that the vertical prefabricated component is combined with the corner connector to bear the load of the horizontal prefabricated component and the load after construction is achieved, erecting and disassembling are convenient, construction is convenient and fast, safety and reliability are achieved, and the hoisting efficiency and construction quality of the prefabricated component are improved.

Owner:GANSU ANJU CONSTR ENG GRP

Modular assembly type automatic lifting tower crane wall-attached working platform

ActiveCN107324225AReduce duplication of laborOutstanding achievements in scientific and technological innovationLifting devicesCranesEngineeringLinkage concept

Owner:陕西华鑫鼎业建筑物资有限公司

A manual steel plate universal cutting and measuring device

ActiveCN105108268BSimple structureEasy to fixWelding/soldering/cutting articlesMetal working apparatusSheet steelTorch

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

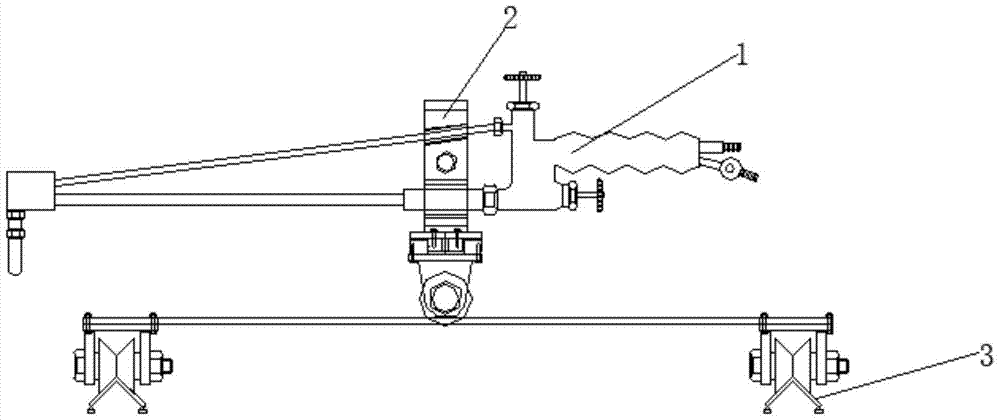

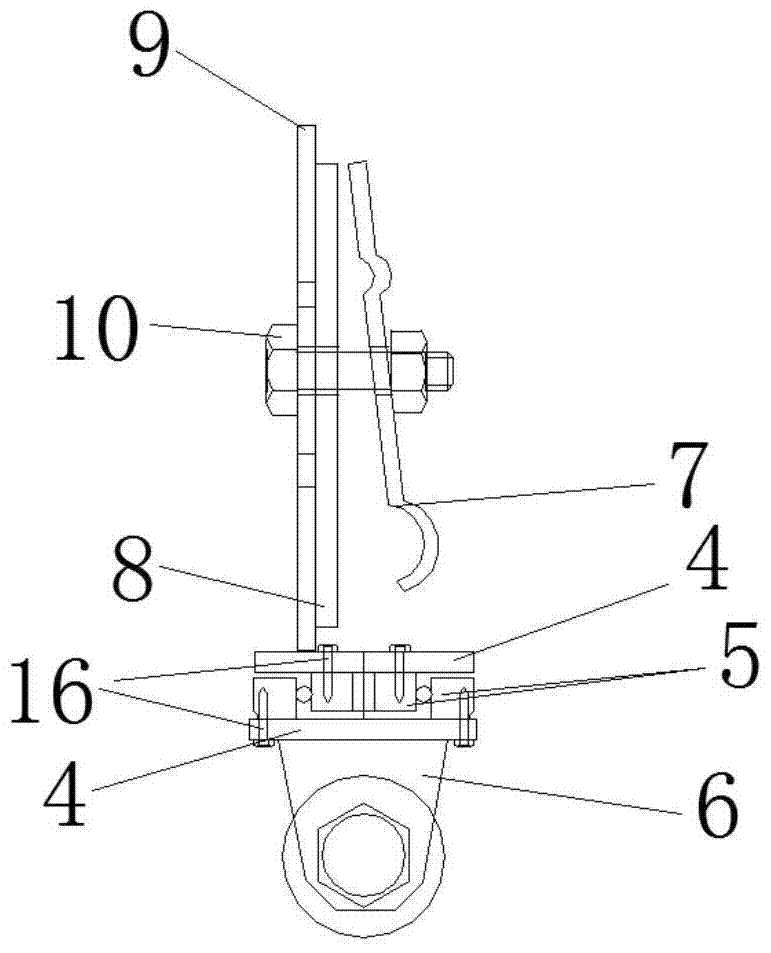

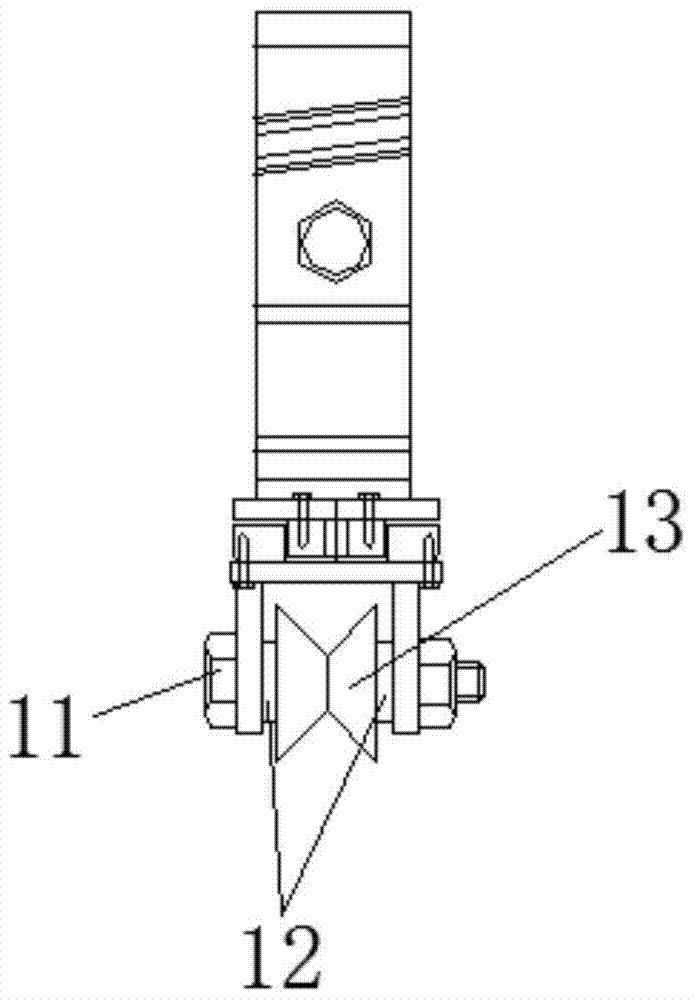

Manual all-directional cutting sizing device for steel plate

ActiveCN105108268ASimple structureEasy to fixWelding/soldering/cutting articlesMetal working apparatusTorchEngineering

The invention discloses a manual all-directional cutting sizing device for a steel plate. The sizing device comprises a cutting torch, a movable device and a sliding device. The movable device comprises a rotating disc, the cutting torch is fixed to the upper portion of the rotating disc, and the sliding device is arranged on the lower portion of the movable device. The movable device can rotate by 360 degrees around the center of the rotating disc and also can move front and back on the sliding device in the direction of the cutting torch so as to adjust the cutting position of the cutting torch, so that all-directional cutting of the cutting torch is achieved. Electromagnetic elements are fixed to the bottom of the sliding device and used for fixing the sliding device to the steel plate to be cut. The sizing device is simple in structure, convenient to fix, build and dismantle and easy to operate on site. The sizing device is flexible to use and capable of being repeatedly used in multi-segment assemblies, so that the cost of circulating materials is lowered. The sizing device can rotate by 360 degrees, cut the steel plate according to different shapes and guarantee cutting continuity; meanwhile, the sliding device is firmly fixed to the steel plate to be cut through the electromagnetic elements, and sliding rails of the sliding device can guarantee cutting stability.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

Method for increasing wall connecting piece and improving and determining bearing capacity of support frame

InactiveCN102182311BSimple structureImprove bearing capacityBuilding material handlingScaffold accessoriesCritical loadWidth ratio

The invention relates to a method for increasing horizontal restraint and improving and determining bearing capacity of a support frame. The support frame is loaded in a 5-span * 5-span range in a mode of longitudinal 8 spans and transverse 6 spans; the support frame is loaded in a mode of 2 spans on one longitudinal side and 1 span on the other side outside the loading area; the support frame is loaded in a mode of 1 span on one transverse side outside the loading area and on span on the other side; the height of the frame is 8.2 meters, the step pitch of upright rods is 1.24 meters, the longitudinal distance between the upright rods is 0.9 meter, the transverse distance between the upright rods is 0.9 meter, the height-width ratio of a bracket is 1.5, and the support frame is erected by using phi48*3.2 steel pipes; each joint is connected through bucklers; adjustable bracket jacking phi48*3.2 double steel pipes are used as supporting load main beams on the upper part of the bracket, the adjustable bracket bottom is inserted in the upright rods of the support frame and is fixed, the distance between the upper surface of an adjustable bracket and the top transverse pipe of the bracket is 0.55 meter, and the adjustable bracket extends out of the upright rods for 0.3 meter and is adjusted in the range of 0.3meter. The invention is characterized in that a horizontal restraint rod is arranged on a reaction frame at the height of 5.3 meters, the critical load loaded to the support frame is 24kN. When the load does not change, the upright rods of the support frame deform greatly, and deform transversely by 12cm-15cm, the upright rods and the horizontal restraint rod are connected through bucklers by a linkage wall rod, the transverse horizontal restrain is increased and the critical load is increased to 26.5KN. By increasing horizontal restrain, improving and determining the support frame loading force, the fastener support frame has economic and reasonable structure, and is safe and practical.

Owner:ZHONGTAI CONSTR GROUP

Cast-in-place concrete structure suspension scaffolding

A suspended scaffolding with a cast-in-place concrete structure is disclosed, which comprises cantilever steel beams, scaffold boards paved on the cantilever steel beams, full-space scaffoldings and template assemblies, wherein a plurality of cantilever steel beams is provided and fixed on the lower set floor board of a precast floor board via anchoring elements; the scaffold boards are paved on the surfaces of the cantilever steel beams; the full-space scaffoldings are erected on the upper parts of the scaffold boards; and the template assemblies are disposed on the parts of the full-space scaffoldings stretching out of the floor board; diagonal draw bars are disposed on the parts of the cantilever steel beams stretching out of the floor board and connected with an anchoring boom on the edge of an upper floor board; diagonal draw wire ropes are further disposed on the parts of the cantilever steel beams stretching out of the floor board and connected with an anchoring ring on the edge of the upper floor board to form a safety device; anti-slip devices are disposed on the inner end parts of the cantilever steel beams and pre-embedded in the floor board. The suspended scaffolding with a cast-in-place concrete structure disclosed by the invention can be used in a construction for a cantilever concrete structure with a random cantilever height and a random floor height. The suspended scaffolding with a cast-in-place concrete structure is wide in application, good in economical efficiency, safe and reliable, light in dead weight, simple in structure, convenient in building and detachment, and high in efficiency.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Reusable anti-climbing device at bottom layer of tower crane on building construction site

ActiveCN102900238BEasy to build and disassembleIn line with the concept of green constructionBuilding material handlingMesh reinforcementArchitectural engineering

The invention relates to a reusable anti-climbing device at the bottom layer of a tower crane on a building construction site. The reusable anti-climbing device is formed by a steel structure framework; and the steel structure frame is composed of stand columns, truss girders, structural cross beams, a door frame, a door, inclined braces, upright poles, connecting pieces, long auxiliary beams, short auxiliary beams and short beams which are connected and combined through bolts and are respectively standard parts with unified specification. The stand columns are connected to four square ground foundations; and the door with a door lock is arranged in the front of the steel structure framework, a reinforcing mesh is laid at the periphery of the steel structure framework, an anti-falling scaffold board is laid on the roof of the upper layer of the steel structure framework, and a color steel plate is laid on the roof of the lower layer of the steel structure framework. The reusable anti-climbing device at the bottom layer of the tower crane on the building construction site is formed by combining the multiple standard parts which are designed according to conditions such as the sizes of standard knots of the tower crane and design codes for lightweight steel structures. The reusable anti-climbing device has the characteristics of being suitable for the sizes of the standard knots at the bottom layers of different tower cranes, capable of being freely combined, convenient, practical and low in cost, and saving labor and time. The reusable anti-climbing device is convenient to dismantle, is in line with a green construction idea and is safe to use on the site.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com