Concrete cylindrical formwork system

A concrete and formwork technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve problems affecting construction efficiency and quality, troublesome splicing, high cost, etc., to prevent molding failure, The structure is simple and the effect of improving the anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

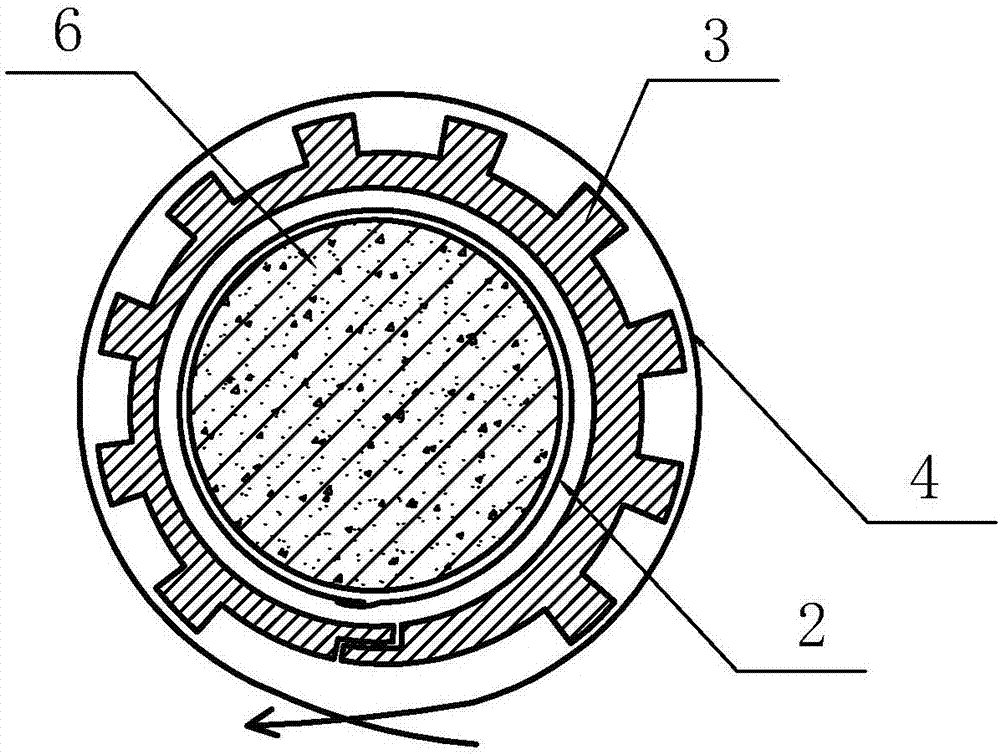

[0036] A concrete cylindrical formwork system such as figure 1 As shown, the concrete cylindrical formwork system includes a lining circle frame 1, an inner lining plate 2, an outer formwork 3 and an outer hoop 4;

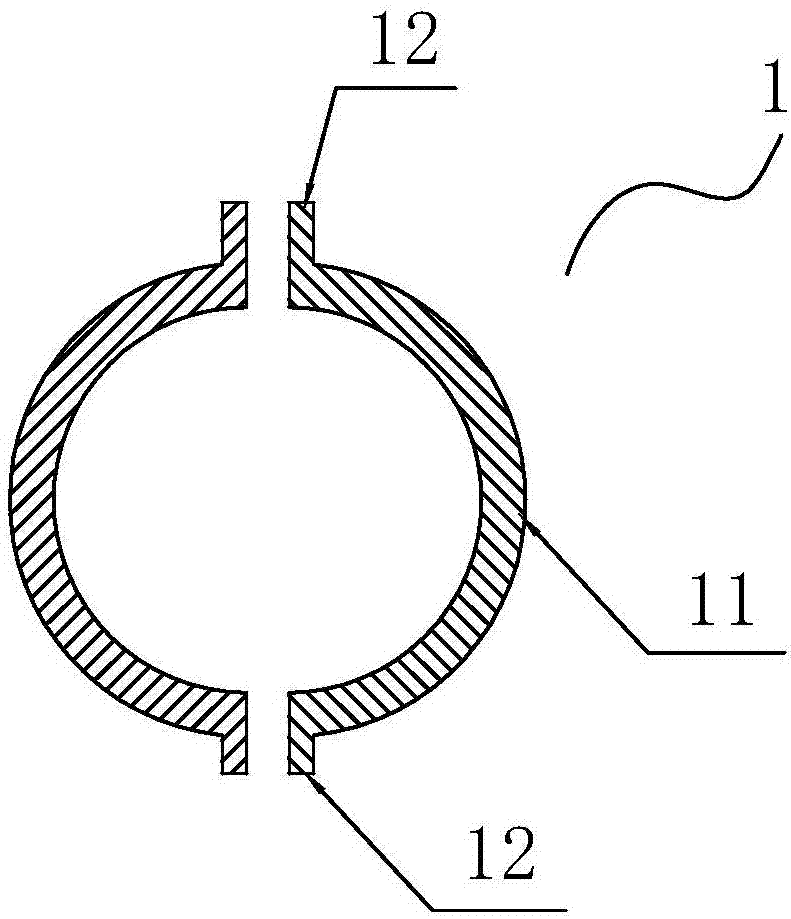

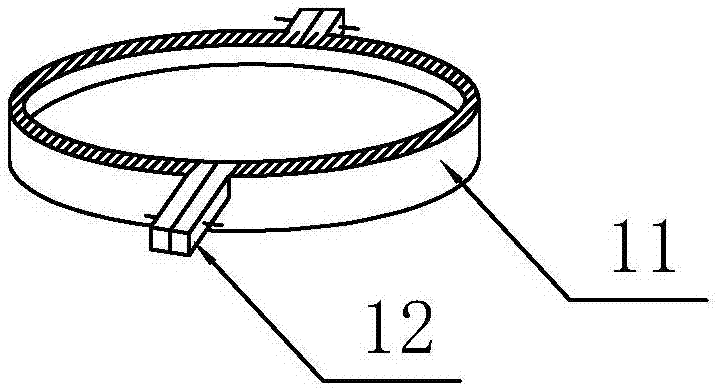

[0037] The inner lining circle frame 1 comprises two semicircular rings 11 butted against each other, and the upper parts of the two ends of the semicircular rings 11 are respectively provided with connecting plates 12 protruding from the outside of the semicircular rings 11 (see diagram 2-1 ), the connecting plate 12 is provided with a bolt hole; the lower part of the semicircular ring 11 is used to cover the inner lining plate 2, and helps the upper end of the inner lining plate 2 to be fixed into a circle. Preferably, the inner lining circle frame 1 is made of aluminum alloy, which is used to check whether the formed cylindrical template is smooth, and helps the upper end of the inner lining plate 2 to be fixed in a circular shape.

[0038] The inner lining pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com