Multi-interface transverse pull rod, simple transverse pull rod, slant bracing rod and tower frame

A tie rod and multi-interface technology, which is applied in the field of simple tie rods, diagonal braces and towers, and multi-interface tie rods, can solve the problems that the tie rods cannot provide connection parts, the stability of the support system is damaged, and the number of fasteners is large. , to achieve the effects of eliminating stability factors, reducing erection costs, and facilitating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

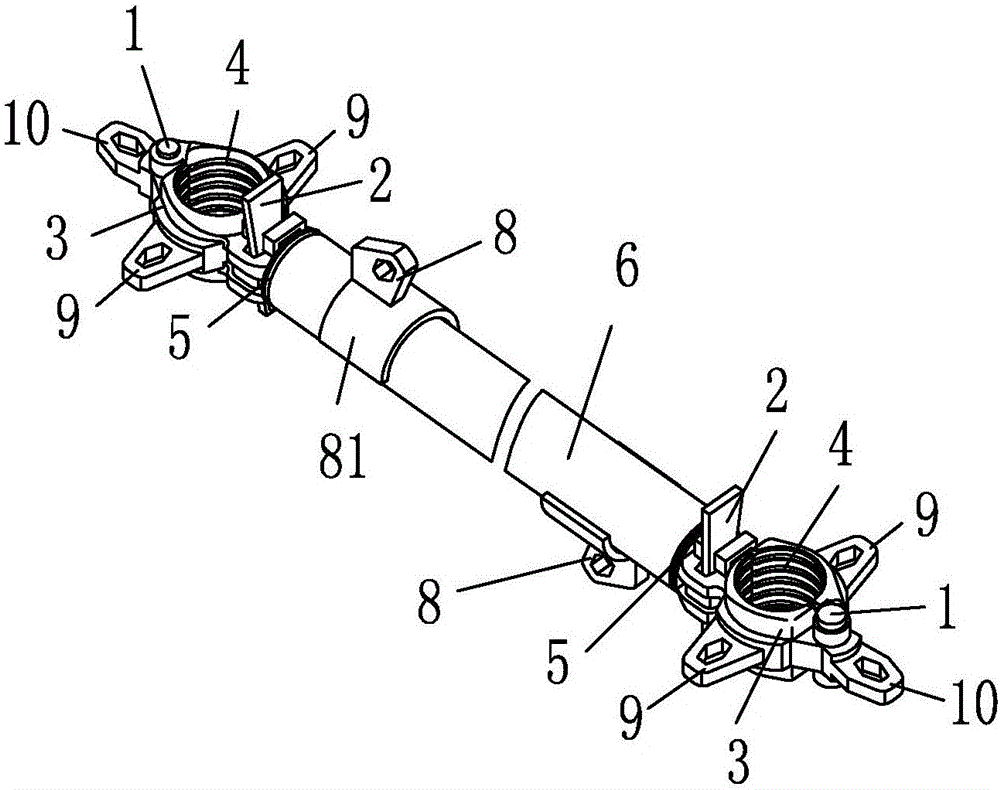

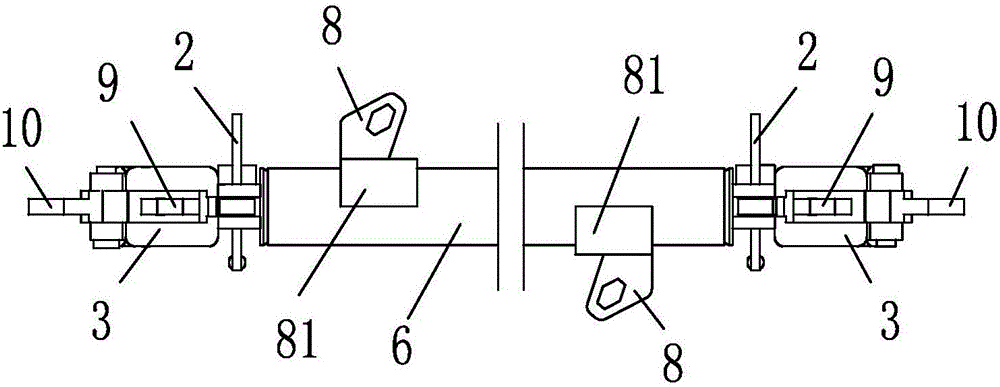

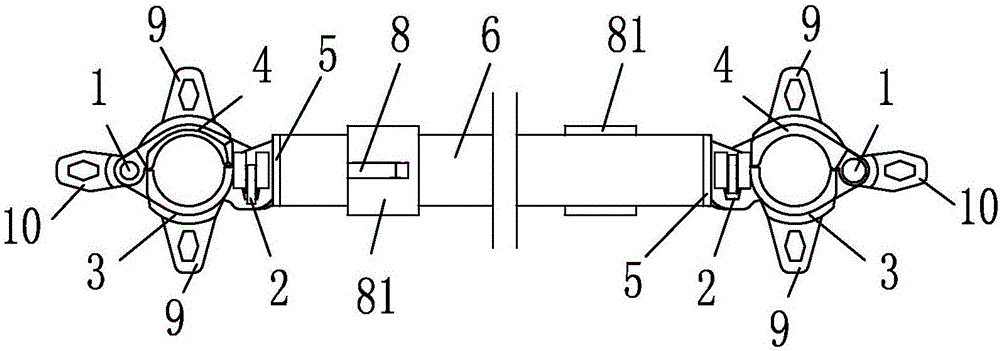

[0040] Example 1, see Figure 1-7 , a multi-interface tie rod, including a tubular tie rod main body 6, the two distal ends of the tubular tie rod main body 6 are fixedly connected with fasteners, and the fasteners include a first semicircular clip hinged by a pin shaft 1 and locked by a wedge 2 The hoop 3 and the second semicircular hoop 4, while the plane passing through the hoop and the axis of the pin shaft 1 constitutes the symmetry plane of the fastener, and the locking or unlocking direction of the wedge 2 is parallel to the symmetry plane; The domes of the semicircle clamp 3 and the second semicircle clamp 4 are provided with a first expansion interface 9, the first expansion interface 9 has a wedge locking structure with a third member, and the first expansion interface 9 is provided with The direction of the first expansion locking hole 9a is parallel to the plane of symmetry; the first semicircular clamp 3 is also provided with a second expansion interface 10; 10 h...

Embodiment 2

[0045] Example 2, see Figure 8 , 9 , 10, a simple horizontal tie rod, comprising a tubular tie rod main body 6 and tie rod joints 12 arranged at both ends of the tubular tie rod main body 6 by welding, a brace interface 8 and a brace interface are respectively provided on the pipe walls at both ends of the tubular tie rod main body 6 8 has a wedge-locked structure with another third component, and the two brace interfaces 8 have a phase difference of 180 degrees; the tie rod joint 12 has a U-shaped fork structure to be connected to the first expansion interface 9 in Embodiment 1, or The plug-type connection ear of the second expansion interface 10 forms a connection structure of plug-in fit, and the rod joint 12 is formed with a strip-shaped joint locking hole 12a for wedge locking, and the length direction of the joint locking hole 12a is in line with the described The axial directions of the tubular tie rod main body 6 are consistent.

[0046] Wherein, the brace interface...

Embodiment 3

[0048] Example 3, see Figure 11 , 12, 13. A diagonal brace, comprising a diagonal brace main body 13, two ends of the diagonal brace main body 13 are provided with a tie rod joint 12, and the tie rod joint 12 has a U-shaped fork structure, which is used for connecting with the diagonal brace in Embodiment 1 or 2. The plug-type connecting ear of the interface 8 forms a connection structure of plug-in fit, and the rod joint 12 is formed with an elongated joint locking hole 12a for wedge locking. The length direction of the joint locking hole 12a is in line with the diagonal brace The axes of the main body 13 are consistent.

[0049] Apparently, the tie rod joint 12 in this embodiment may also have a connection structure of a plug-in type connection ear, which has formed a connection structure of plug-fitting with the brace interface 8 of the U-shaped fork structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com