External wall construction hanging bracket and installation method thereof

A hanger and exterior wall technology, which is applied in the direction of scaffolding supported by house structure, house structure support, house structure support, etc., can solve the problems of inability to move as a whole, inconvenient operation, time-consuming and labor-intensive scaffolding, etc. The effect of reasonable and stable force and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

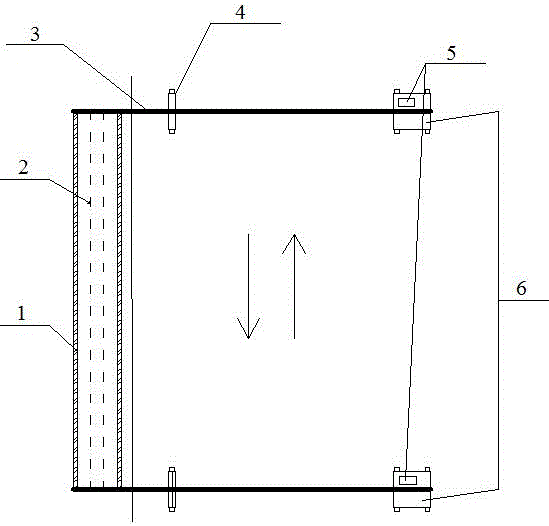

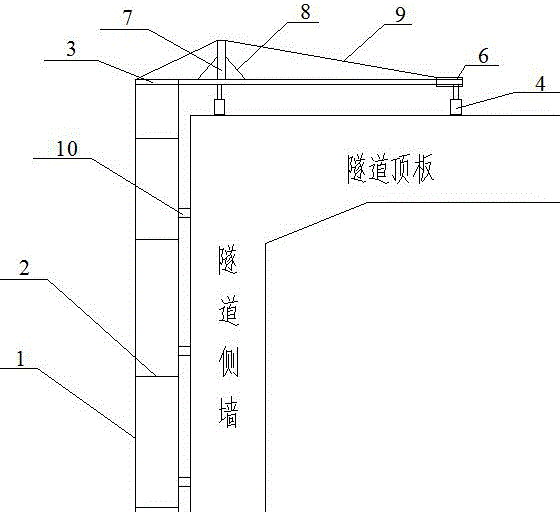

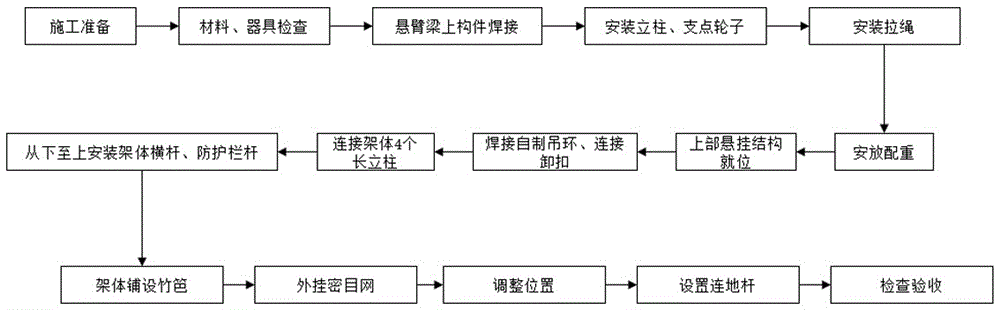

[0027] Such as Figure 1-2 A hanger for exterior wall construction shown includes a suspension structure, a frame body and an operating platform 2, the suspension structure is connected to the frame body, and several sets of operating platforms 2 are arranged on the frame body; the suspension structure includes a suspension beam, a column, a suspension wire, The counterweight 5 and the counterweight placement platform 6, the frame body includes the frame body skeleton 1, the operation platform 2, guardrails and ground parts, the suspension beam 3 is set on the counterweight placement platform 6, the upright column is set on the suspension beam 3, and the suspension wire 9 The two ends are arranged on the two ends of the suspension beam 3 after passing through the column, the suspension beam 3 and the frame body skeleton 1 are connected by connecting buckles, and an adsorption device 10 is provided on the guardrail.

[0028] The invention solves the problem of consuming a lot o...

Embodiment 2

[0030] Such as Figure 1-2 In the shown hanger for external wall construction, the suspension beams 3 have at least two groups, the two sides of the columns on the suspension beams 3 are provided with fixed rods 8, the upper ends of the columns 7 are provided with grooves, and the suspension wires 9 pass through the grooves. The distance between the column 7 and the counterweight 5 is 2 to 4 times the distance between the column 7 and the frame body. The bottom of the counterweight placing platform 6 is provided with rollers, and the number of suspension beams 3 is not less than two. The ground connecting parts are arranged at the bottom of the frame body frame 1, the operating platform 2 is evenly distributed on the frame body frame 1 and arranged vertically with the frame body frame 1, the guardrails are arranged on both sides of the operating platform 2, and the outside of the operating platform 2 is provided with protection network. Other structures are the same as in Em...

Embodiment 3

[0032] Such as Figure 1-2 In the shown hanger for external wall construction, the frame body skeleton 1 includes several groups of vertical rods, the vertical rods are telescopic, connecting rods are arranged between the vertical rods, and the operating platform 2 is laid on the connecting rods. The device 10 is a suction cup or a fixed claw. The counterweight placing platform 6 is a frame structure, and the counterweight placing platform 6 is provided with a load cell, a controller and a counterweight adjuster, and the load cell and the counterweight adjuster are connected to the controller through wires. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com