Method for increasing horizontal cross braces and improving and determining bearing capacity of support frame

A support frame and scissors technology, applied in the field of support frames, can solve problems such as safety hazards, safety accidents, material waste costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

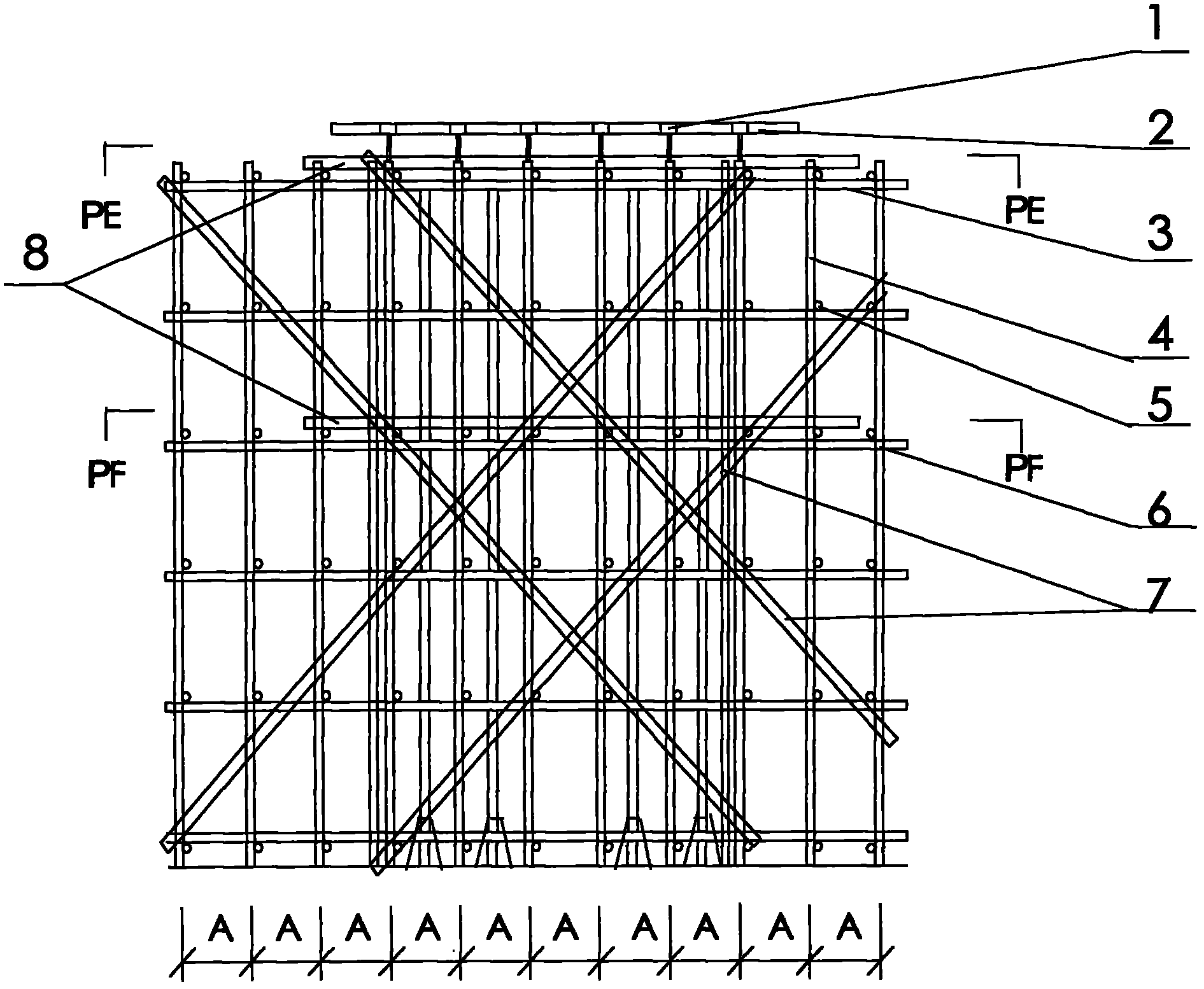

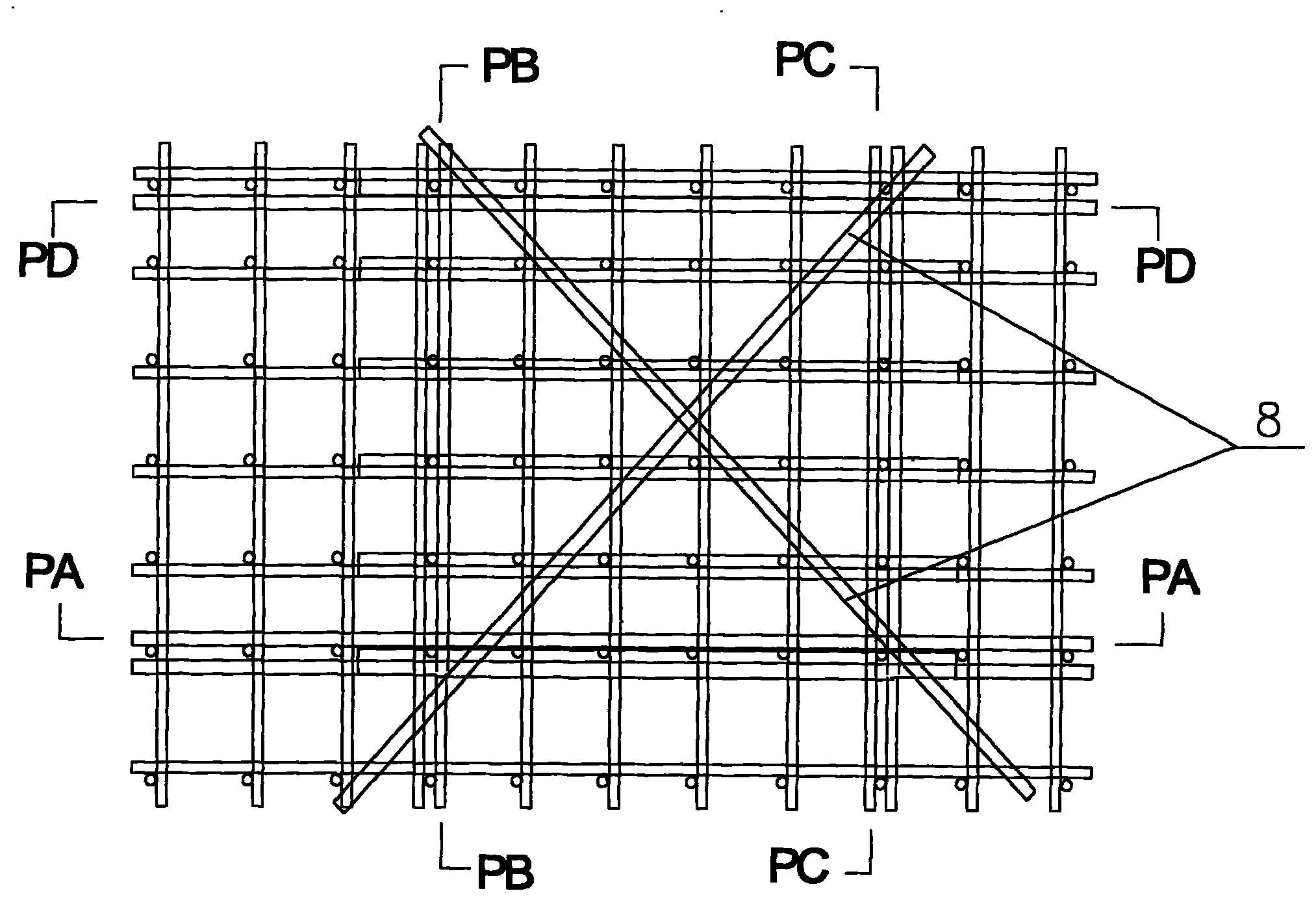

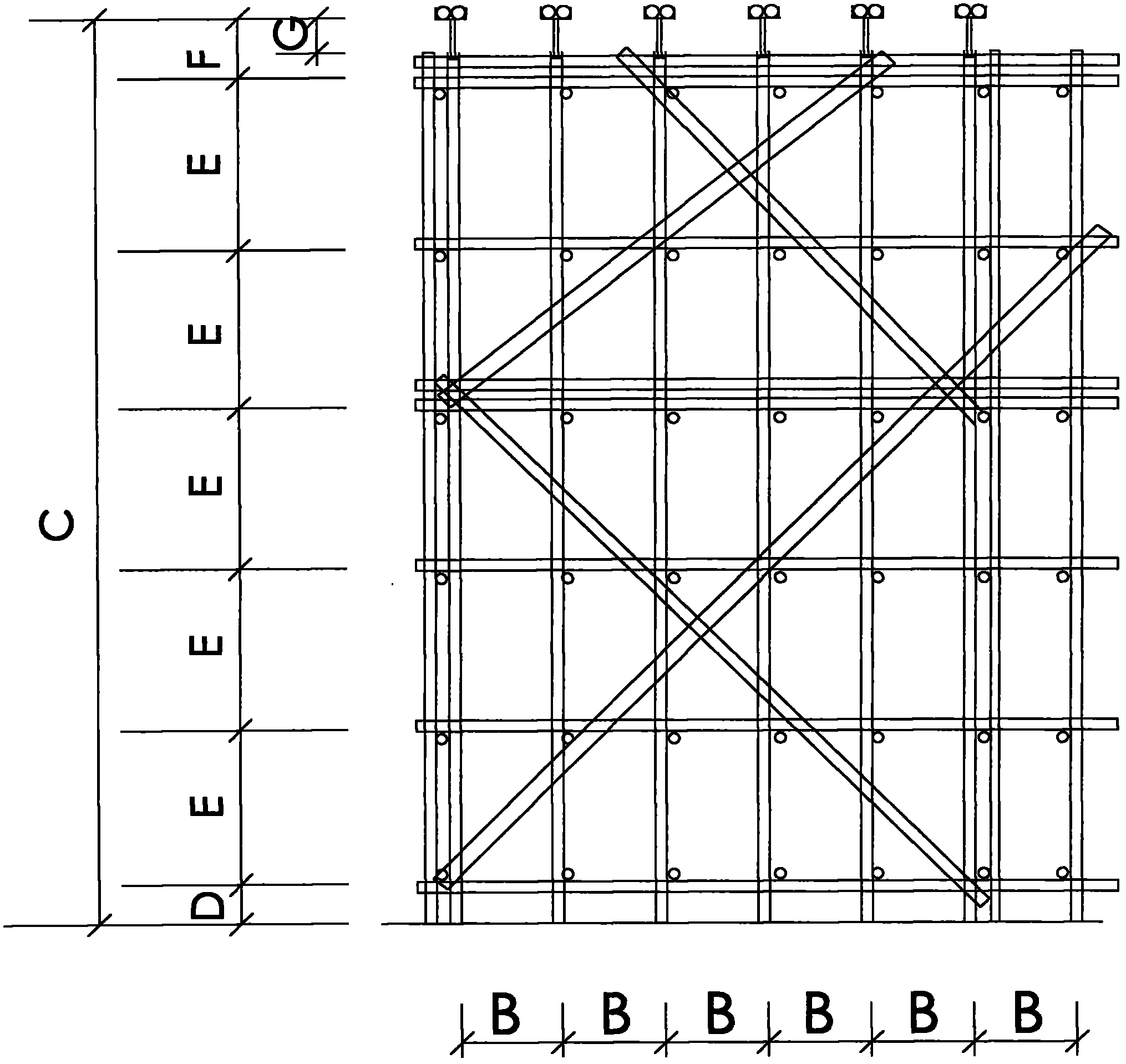

[0015] like Figure 1~3 As shown, the support frame includes a vertical steel pipe 4, a vertical horizontal bar 3, a horizontal horizontal bar 5, and a malleable iron fastener 6; 3 spans on one side, 2 spans on the other side; 1 span on the lateral side outside the loading area, no additional span on the other side; erection height 8.2m, pole step distance 1.5m, vertical pole spacing 0.9m, vertical pole horizontal spacing 0.9m; set vertical scissor braces 7 for every four rows of vertical poles in the vertical section or elevation around the loading area. 8 horizontal scissor braces are set on the horizontal plane of the first row of nodes and the third row of nodes in the range. The scissor braces are close to the nodes and fastened with fasteners at the junction of the horizontal rod or vertical rod; the support frame vertical rod, horizontal rod, scissors brace All use Φ48×3.2 steel pipes, and each node is connected with fasteners; the upper part of the bracket is supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com