A manual steel plate universal cutting and measuring device

A movable device and sliding device technology, applied in welding/welding/cutting items, gas flame welding equipment, manufacturing tools, etc., can solve the problems of stable cutting deflection, affecting the blanking size, cutting discontinuity, etc. Stability, easy to assemble and disassemble, to ensure the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

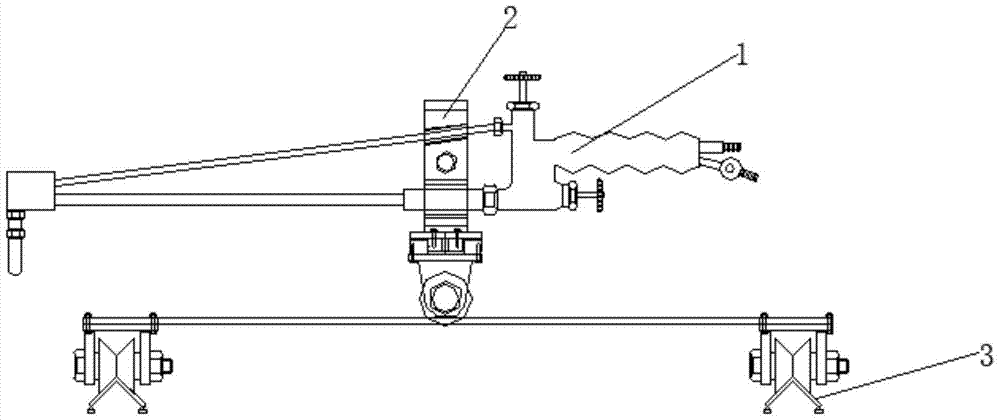

[0028] Such as figure 1 As shown, the manual steel plate universal cutting and sizing device consists of a cutting torch 1, a movable device 2, and a sliding track 3.

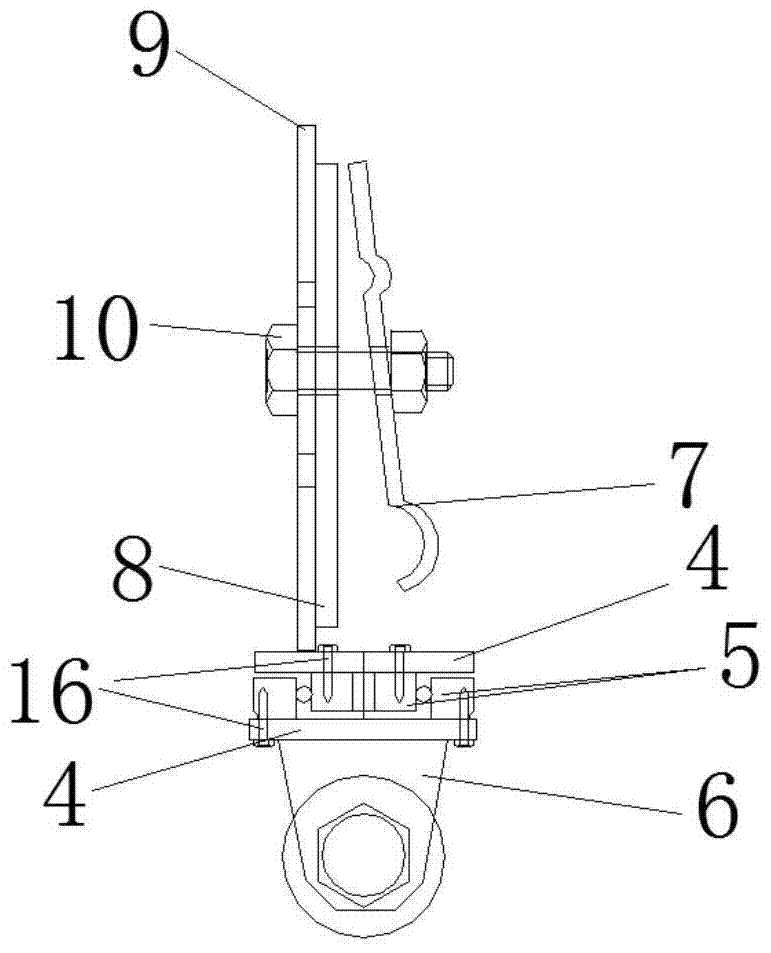

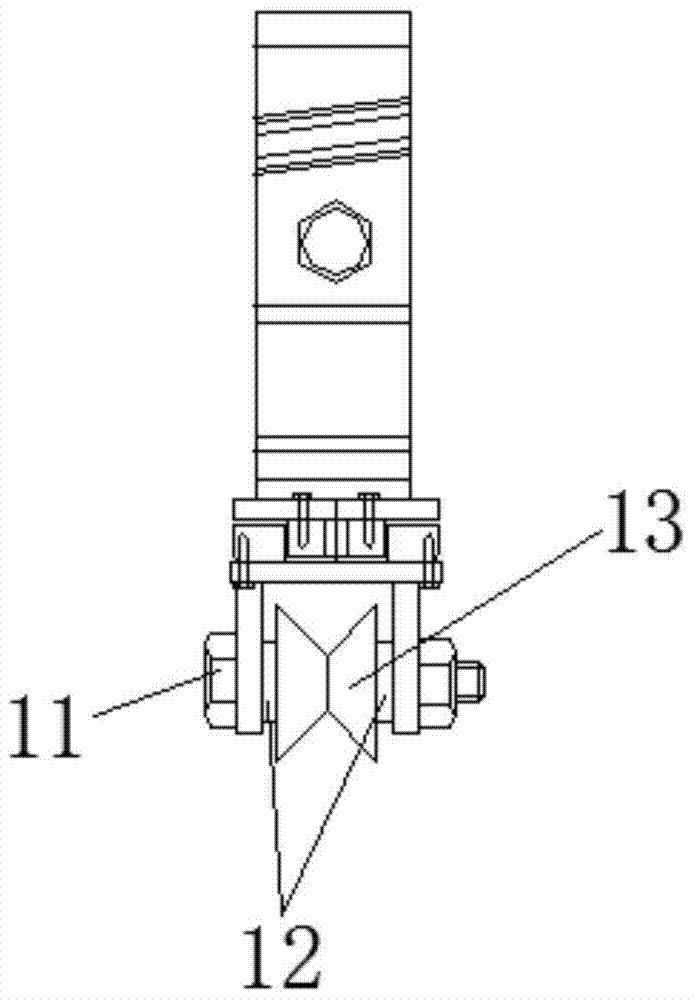

[0029] Such as Figure 2-Figure 3 As shown, the pulley 13 is placed between two δ6 trapezoidal steel plates 6, the included angle of the pulley 13 is 90°, two pulley spacers 12 are installed between the pulley 13 and the trapezoidal steel plates, and the pulley 13 and the δ6 trapezoidal steel plates are connected by M8 bolts 11. 6. The pulley gasket 12 is reinforced in series.

[0030] The upper parts of two δ6 trapezoidal steel plates 6 are welded with δ3 steel plates 4, and the outer race of the turntable 5 is connected with bolts on the steel plates 4, and the inner race of the turntable 5 is connected with the δ3 steel plates 4 above it with bolts. The delta 6 perforated steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com