Formwork early removing mechanism and early removing formwork system

A formwork and system technology, which is applied to formwork/formwork/work frame, formwork treatment, building structure, etc. The effect of early demolition and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

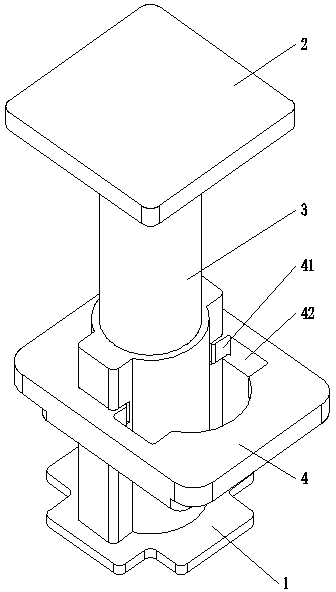

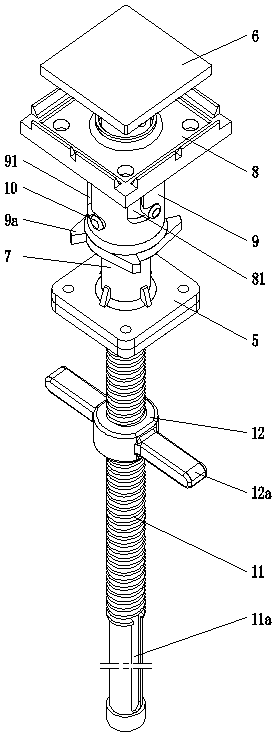

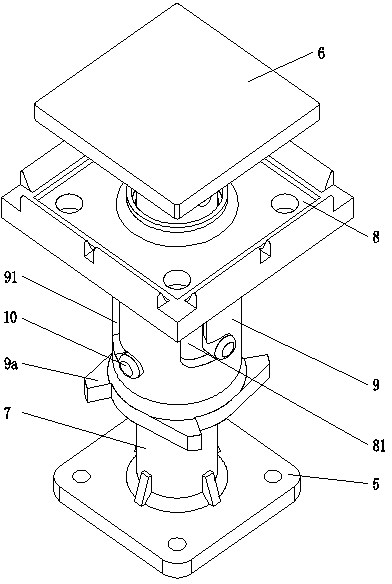

[0046] Example 1 see figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 9 , a template early dismantling mechanism, including a bottom plate 5, a top plate 6, a pillar 7, and a bracket 8, the pillar 7 is arranged between the bottom plate 5 and the top plate 6, and the bracket 8 is slidably socketed on the pillar through a guide sleeve 81 extending downward 7, the bracket 8 below is provided with a bracket support sleeve 9 that can hold it up, and the bracket support sleeve 9 is provided with a support arm 9a for making it rotate. On the guide sleeve 81 of the bracket 8, the wall There is a guide groove 82 that is vertical and runs through the thickness of the tube wall; the movable ring of the bracket support sleeve 9 is sleeved on the outer circumference of the guide sleeve 81 of the bracket 8, and the tube wall of the bracket support sleeve 9 is provided with a wall along the tube wall. A chute 91 that extends spirally upwards and runs through the th...

Embodiment 2

[0051] Example 2 see Figure 7 , Figure 8 , Figure 9 , an early dismantling formwork system, comprising a plurality of support columns 13 and formwork components, the support columns 13 are provided with early dismantling mechanisms, a plurality of early dismantling mechanisms form a support for the formwork components, and the top plates and formwork components of the multiple early dismantlement mechanisms Forming the lower formwork of the casting body, the early dismantling mechanism is the formwork early dismantling mechanism described in Embodiment 1 of the present invention.

[0052] Described formwork early dismantling mechanism is supported on support column 13 upper ends by nut 12, and guide bar 11 stretches in the tube hole of support column 13 upper ends, and support column 13 is provided with and is used to limit the guide pin that formwork dismantling mechanism rotates early by guide groove 11a 131.

[0053] The formwork assembly is supported by the brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com