Cast-in-place box girder side web plate and wing plate integration supporting frame

A technology with integrated wings and support frames, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult control of line shape, cumbersome erection methods, and difficult adjustment, and achieve easy control, material saving, and structural line shape Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

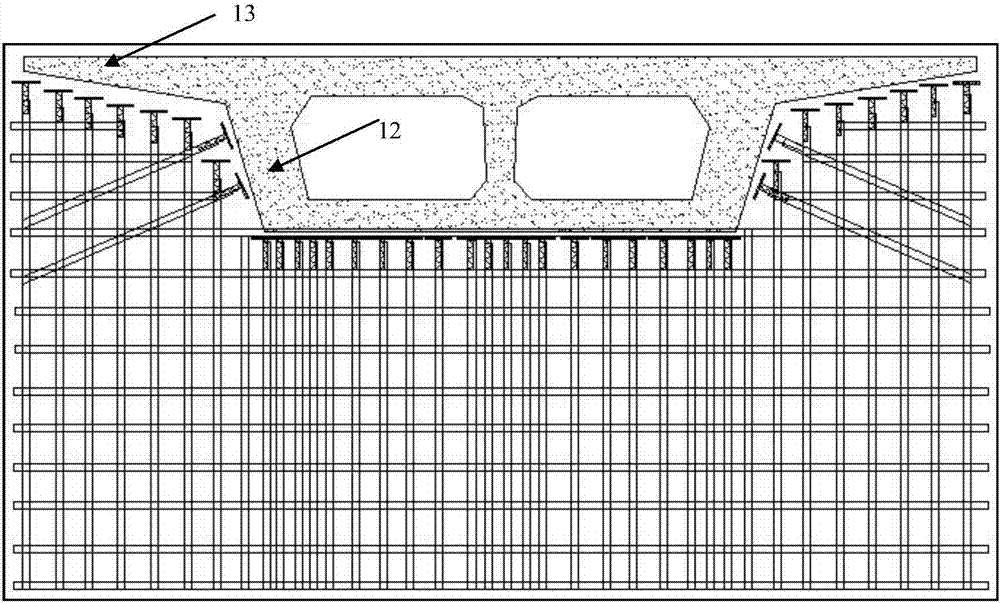

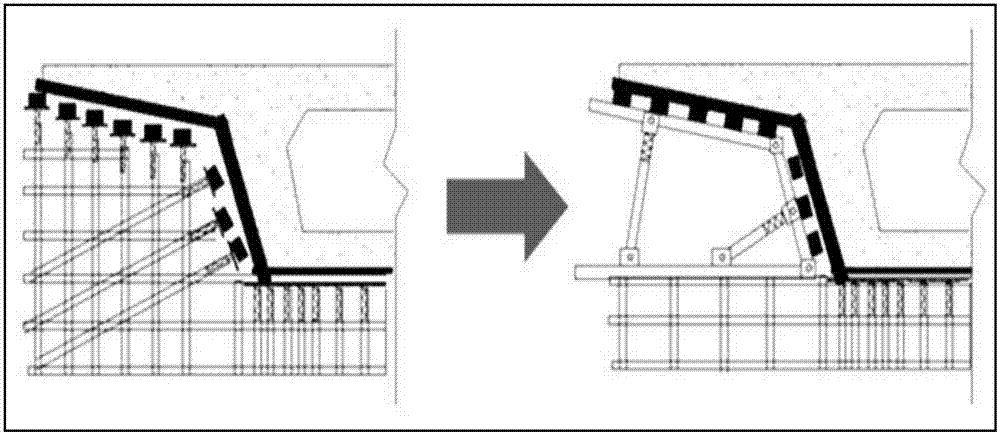

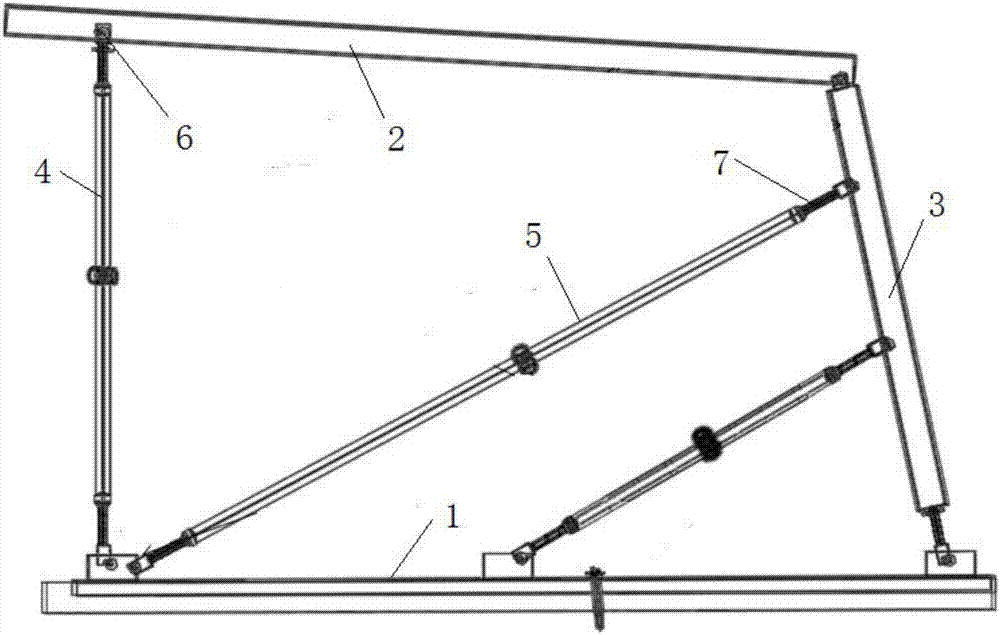

[0036] The present invention aims at the defects of the conventional support frame at the side web 12 and the wing plate 13 of the cast-in-place box girder. and the wing plate support frame for R&D and design, and finally invented a simple assembly and disassembly, convenient adjustment, easy control and inspection, especially for the box girder of the cast-in-situ box girder bridge width gradient section (curve section, lane change section, main line connection) ramp section, etc.), where the line shape of the side web 12 and the wing plate changes a lot, it is more conducive to its line shape control, and conforms to the relevant codes, standards and design requirements. In order to achieve the purpose of guaranteeing construction quality, improving construction efficiency and saving resources. The present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] The cast-in-place box girder side web 12 and the integral support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com