Hydraulic self-sealed milk storage tank structure

A self-sealing, milk tank technology, used in containers, packaging, transportation and packaging, can solve problems affecting the quality of fresh milk, avoid the entry of external bacteria, improve sealing performance, and improve sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

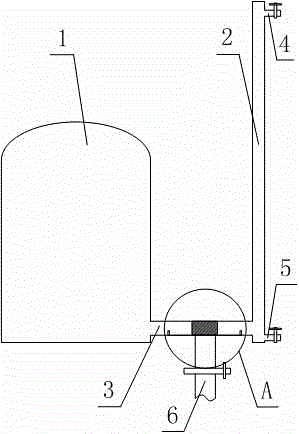

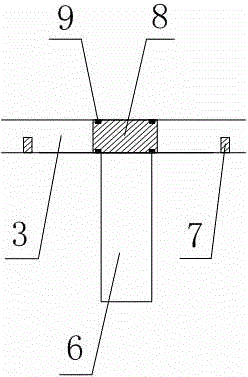

[0019] Such as figure 1 and figure 2 The structure of a hydraulic self-sealing milk storage tank shown includes a tank body 1 and a vertically arranged pressure pipe 2, the pressure pipe 2 is arranged on the same level as the tank body 1, and the pressure pipe 2 2 The height is greater than or equal to 1.5 times the height of the tank body 1, the top of the pressure pipe 2 is provided with a water inlet 4, and the bottom of the pressure pipe 2 is provided with a drain port 5; the pressure pipe 2 and the tank body 1 are connected through a horizontally arranged flow channel 3, said A discharge pipe 6 is arranged in the flow channel 3, and both sides of the discharge pipe 6 in the flow channel 3 are provided with stoppers 7, and a slider 8 having the same shape and size as the flow channel 3 is arranged between the two stoppers 7; The left and right ends of the slider 8 are provided with sealing grooves 9, and rubber sealing rings are arranged in the sealing grooves 9; the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com