A mobile rod receiving and blanking device

A technology of blanking device and receiving device, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., which can solve problems such as prone to wrong roots, chaotic bundling, and backward alignment technology, and achieve stable blanking and bar material The effect of neat arrangement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

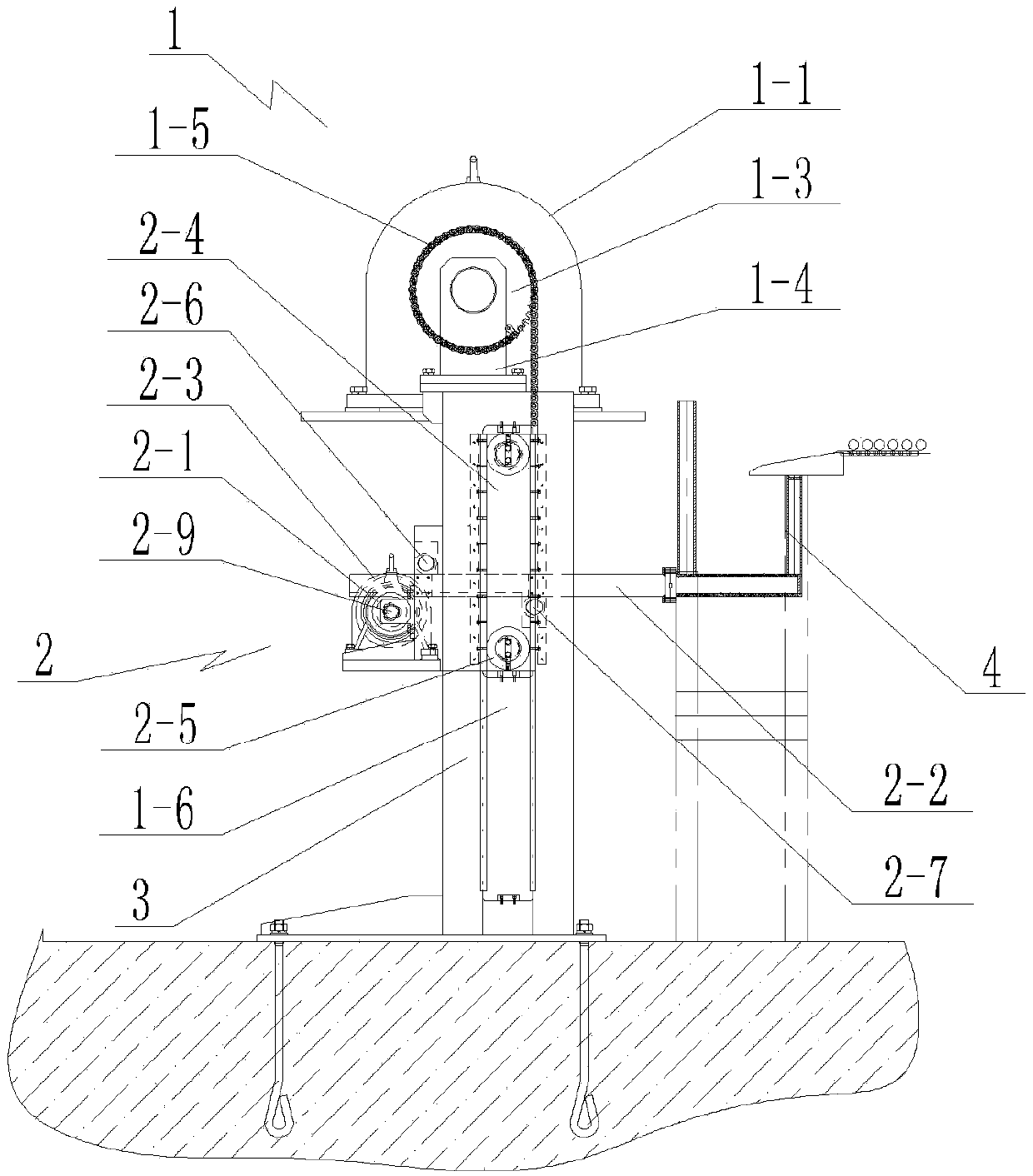

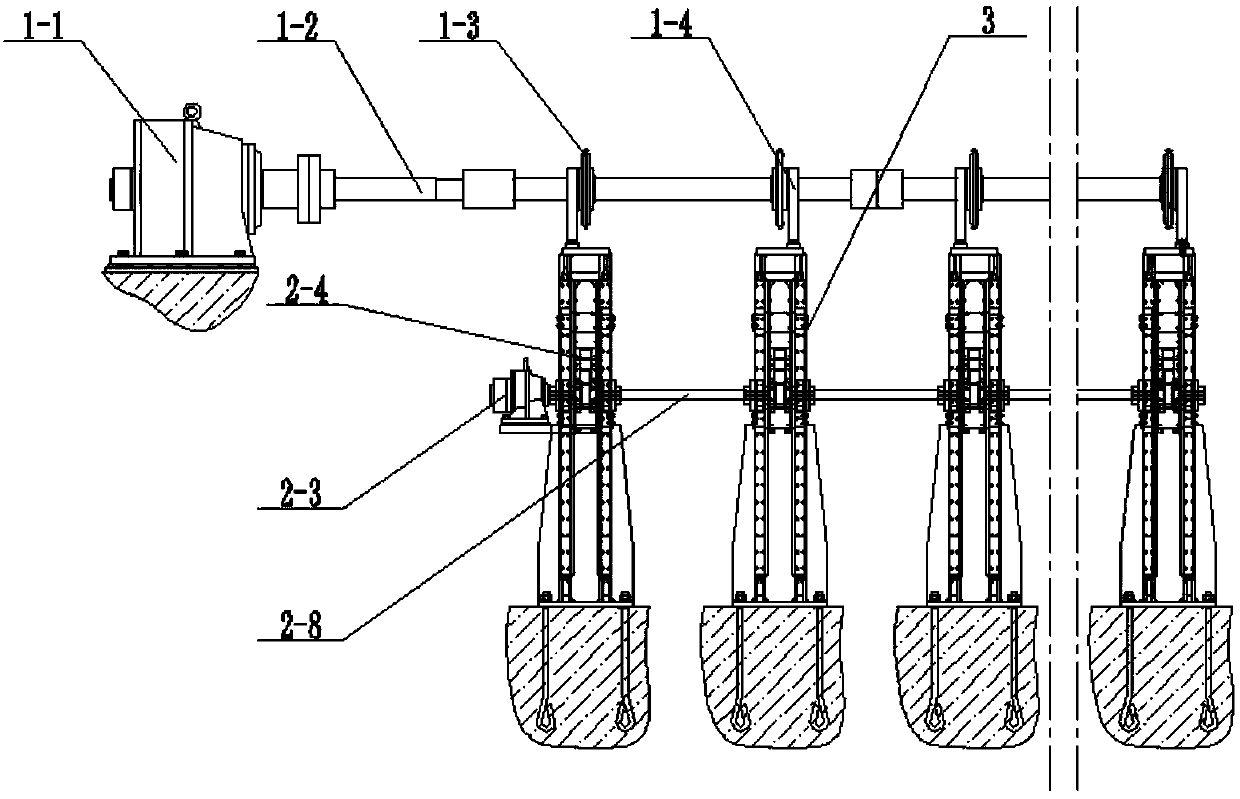

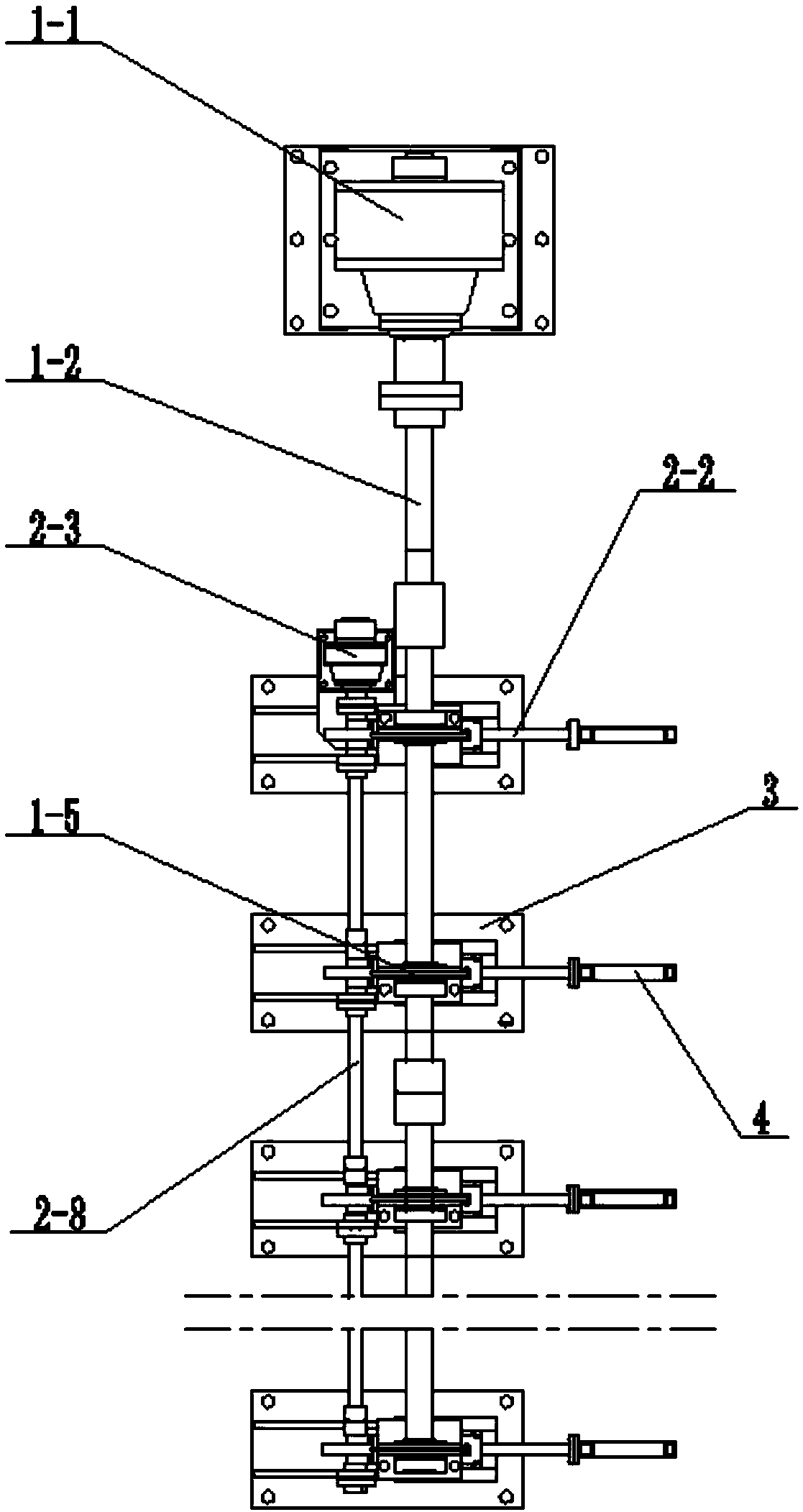

[0014] Such as Figure 1 to Figure 3 As shown, a mobile bar receiving and blanking device in this embodiment, wherein: it includes several frames 3, material frame 4, lifting device 1 and translation receiving device 2;

[0015] The several frames 3 are vertically installed on the foundation, guide grooves 1-6 are arranged in the middle of both sides of each frame 3, a lifting device 1 is arranged on the top of the frame 3, and a translation receiving device 2 is arranged on The middle of the frame 3 is connected with the lifting device 1, and one end of the rack 2-2 in the translation receiving device 2 is connected with the lower part of one side of the material frame 4, and the material frame 4 is located above the roller table of the baler when receiving materials .

[0016] The lifting device 1 includes a first belt motor reducer 1-1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com