Synchronous chamfering device for four corners of cutting board

A technology of chamfering device and cutting board, applied in the field of machinery, can solve the problems of short board, influence and low efficiency of wooden barrels, and achieve the effect of ensuring synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

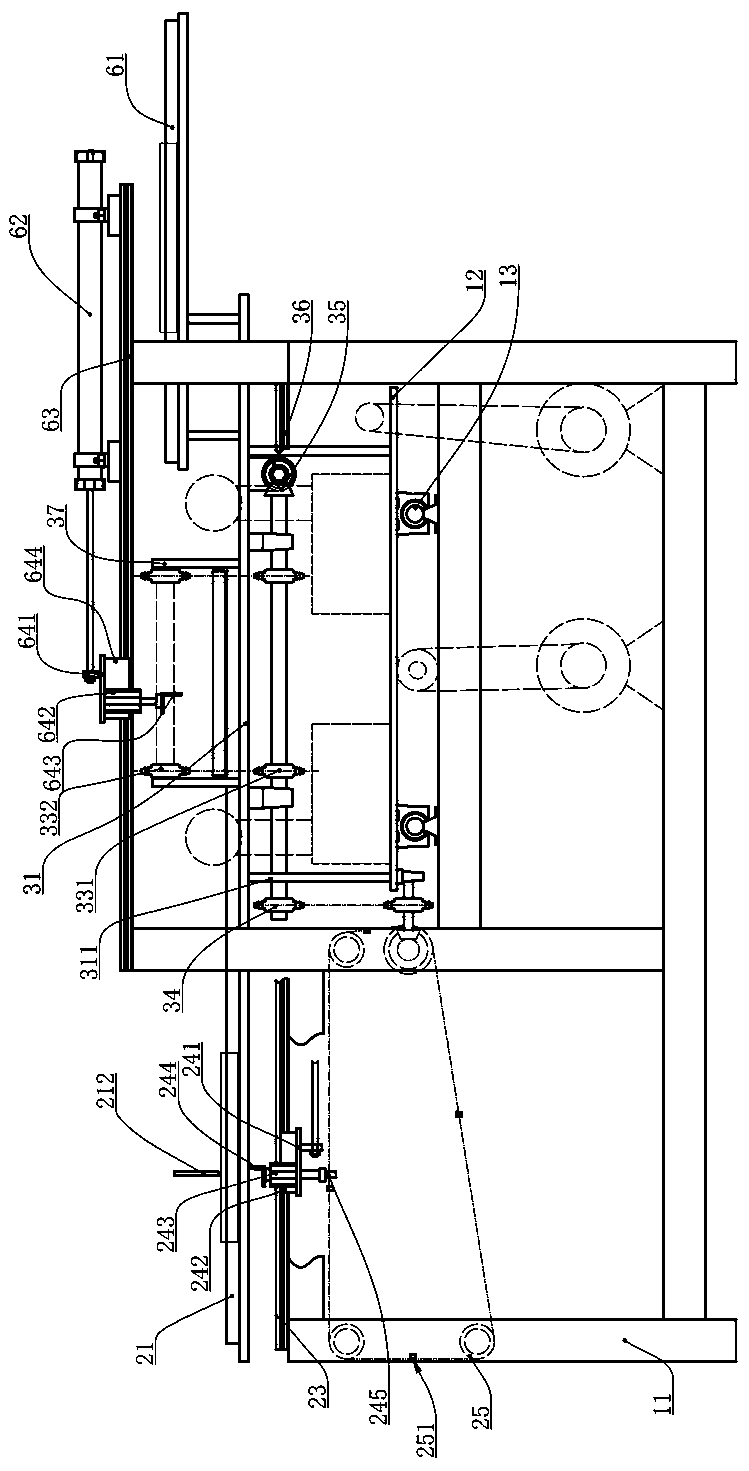

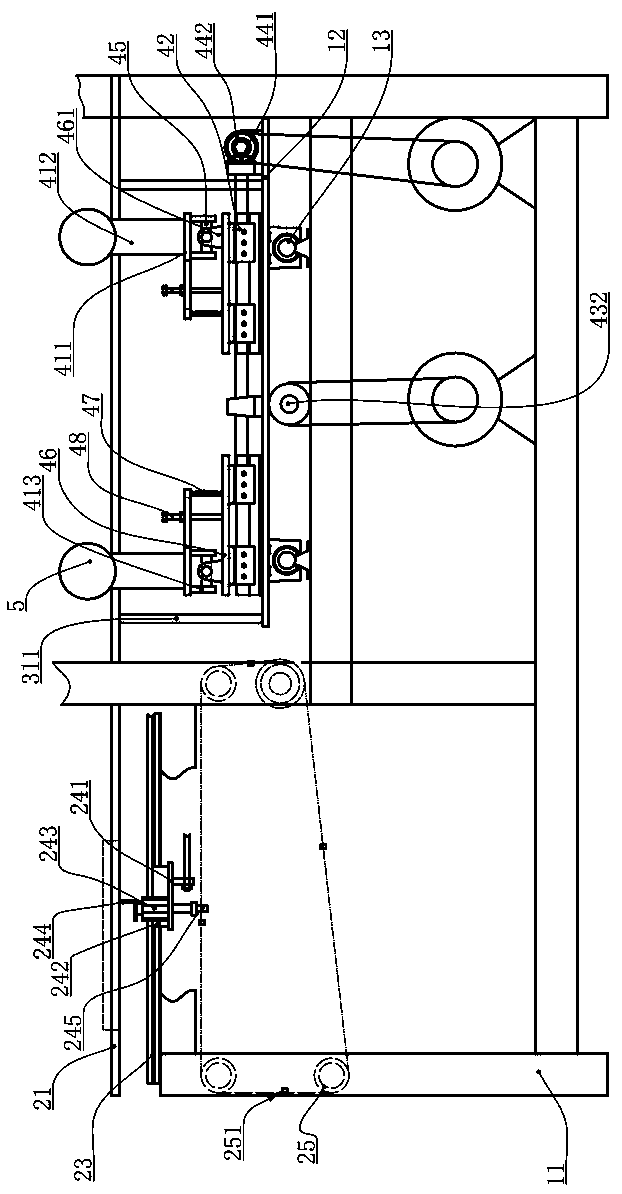

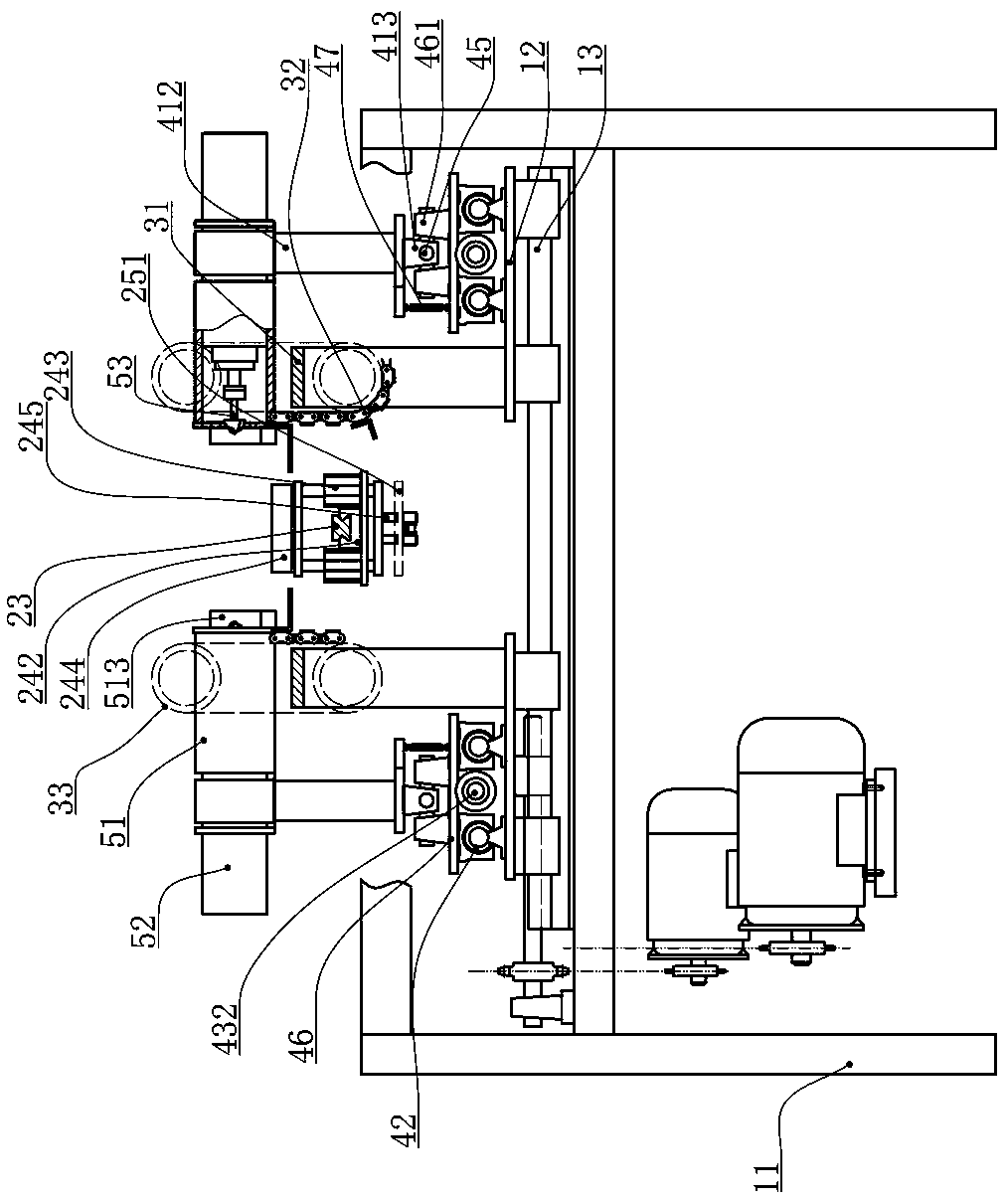

[0052] Referring to the accompanying drawings, the structure and working principle of the chamfering device of the present invention will be further explained by taking a cutting board automatic chamfering processing equipment using the chamfering device of the present invention as an example.

[0053] refer to Figure 1-12 , shown in this example is a kind of cutting board automatic chamfering processing equipment, including frame 11, with the cutting board being conveyed as the front, feeding mechanism, cutting board chamfering device, and discharging mechanism are arranged successively on the frame from back to front.

[0054] The feeding mechanism includes a feeding table 21 and a feeding cylinder 22. The feeding table 21 is used to carry the transmitted cutting boards, and the feeding cylinder 22 pushes the cutting boards on the feeding table 21 to the chopping block chamfering device one by one.

[0055] The feeding table 21 is composed of two table boards arranged along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com