Clamping enhanced type electronic connector side perforating device

An enhanced technology for electronic connectors, applied in positioning devices, clamping, boring/drilling, etc., can solve the problems of small size of electronic connectors, difficulty in side drilling, unstable structure, etc., and achieve increased pressure resistance Effects of friction, ease of operation, and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

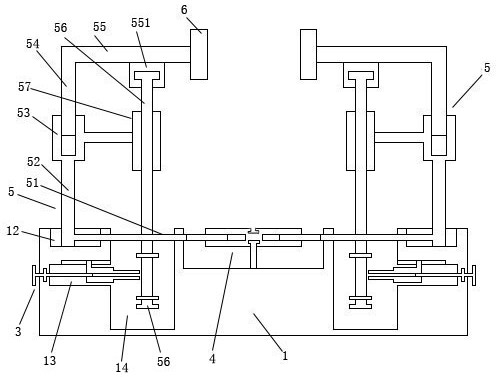

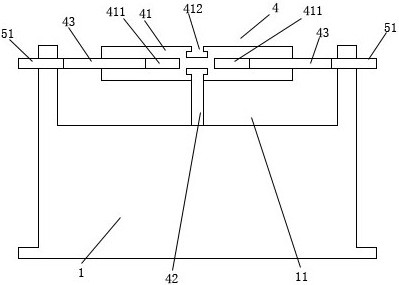

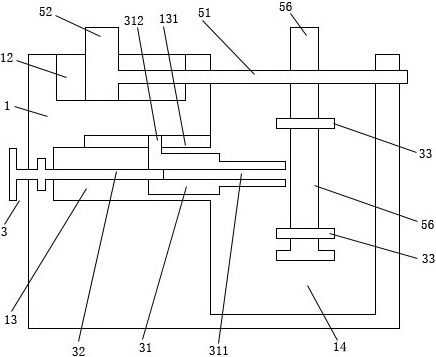

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] Such as Figures 1 to 6 As shown, a clamping enhanced electronic connector side hole opening device includes a base 1, a telescopic movement mechanism 5, a clamping plate 6, a driving mechanism 4, and an abutting rubber plate 2; the telescopic movement mechanism 5 includes a mobile Plate 51, sliding clamping rod 52, moving column 53, floating rod 54, horizontal plate 55, positioning threaded cylinder 57, driving screw 56; a telescopic moving mechanism 5 is respectively installed on both sides of the upper end of the base 1; the base 1 The two sides of the upper end of the upper end are respectively provided with sliding card slots 12; on the said sliding card slots 12, a sliding card connecting rod 52 is installed for sliding card connection; a moving plate 51 is installed on the inner side of the lower end of the said sliding card conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com