Passenger car fuel tank fixing mechanism

A technology for fixing mechanisms and fuel tanks, which is applied to vehicle components, the arrangement combined with the fuel supply of internal combustion engines, power devices, etc., can solve the problems of complex structure, difficult disassembly of fuel tanks, high manufacturing costs, etc., achieve good stability, improve convenience, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

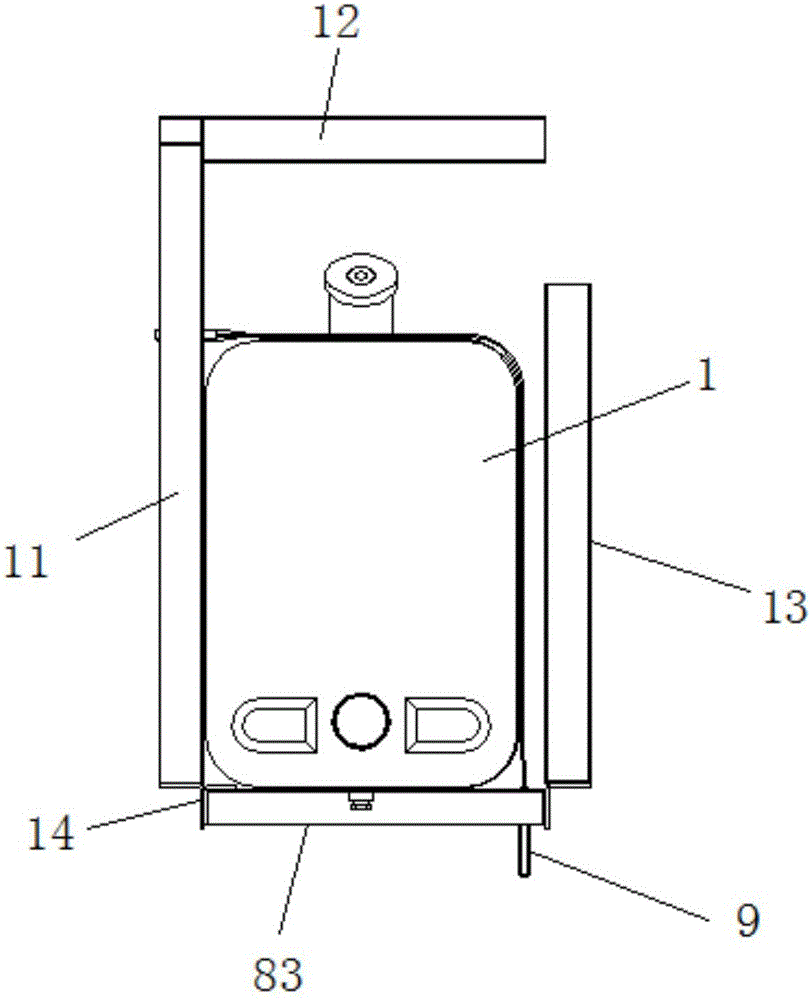

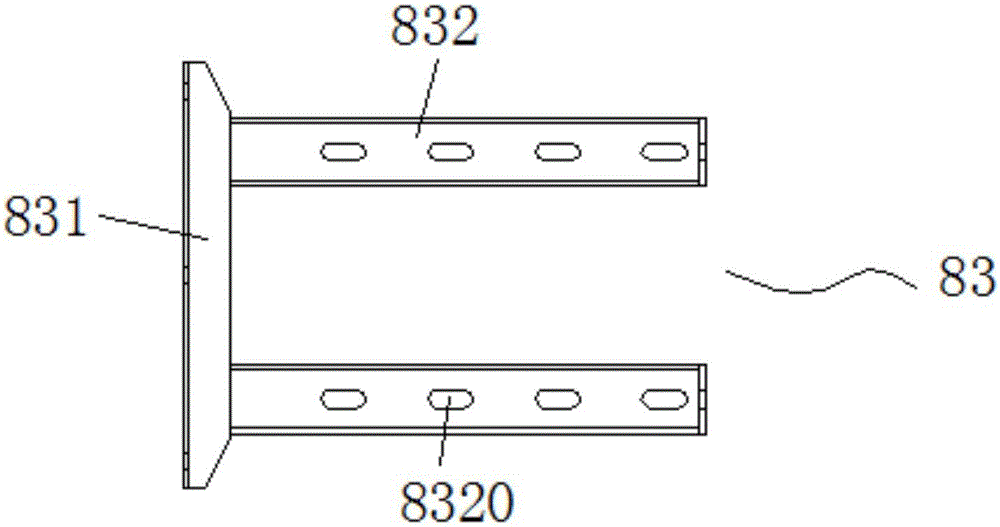

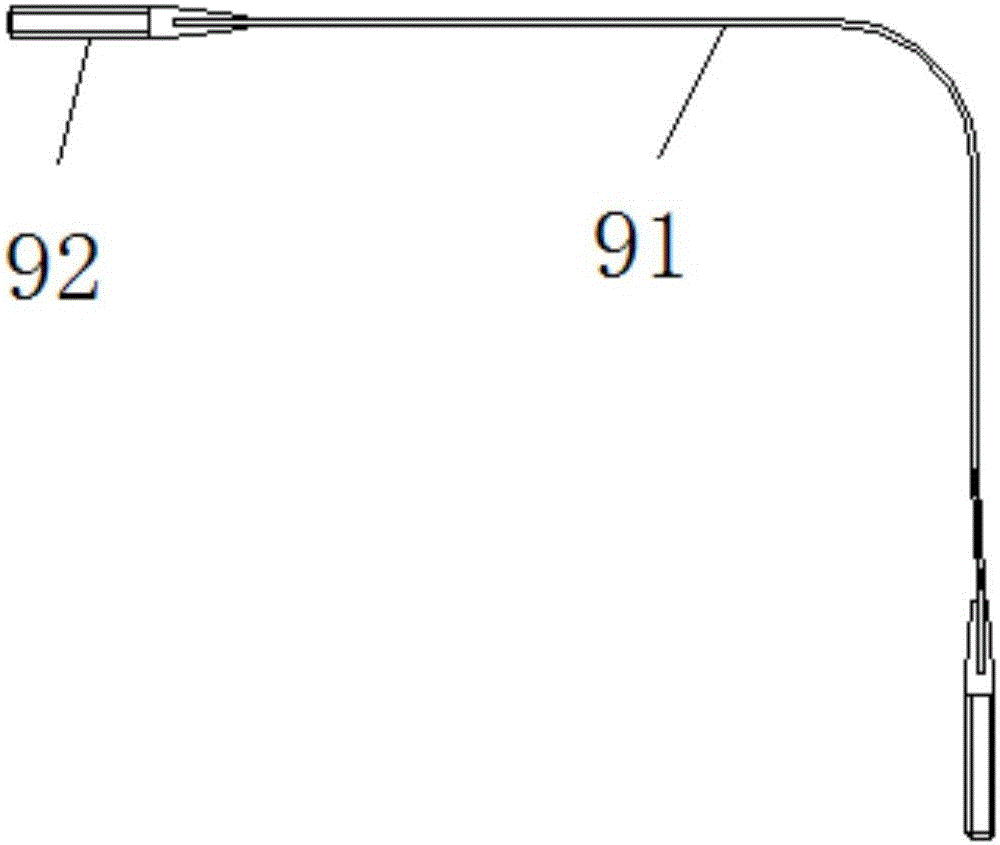

[0015] Such as Figure 1 to Figure 3 As shown, a passenger car fuel tank fixing mechanism of the present invention includes installation vertical beam 11, installation beam 12, baffle plate 13, angle steel 14, support frame 83 and fuel tank fastening belt 9, and installation vertical beam 11 and baffle plate 13 are arranged in parallel, The installation beam 12 is fixedly connected to the top of the installation vertical beam 11, and the two ends of the support frame 83 are fixedly connected to the bottom end of the installation vertical beam 11 and the bottom end of the baffle plate 13 by two angle steels 14 respectively. The fuel tank 1 of the passenger car is fixedly connected to the support frame 83, the fuel tank fastening belt 9 is covered on the fuel tank 1, and one end of the fuel tank fastening belt 9 is fixedly connected to the installation vertical beam 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com