A dynamic penetrometer automatically considering energy correction and dynamic response

A technology of dynamic response and penetrometer, which is applied in the fields of on-site foundation soil survey, construction, and basic structure engineering, etc., which can solve the problem of inability to effectively detect the properties of hard soil layers penetrated, reduce the engineering application value of soil parameters, and fail to represent Problems such as the original state index of the soil layer, to reduce the influence of temperature and bending effects, shorten the evaluation cycle, and reduce the cost of investigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

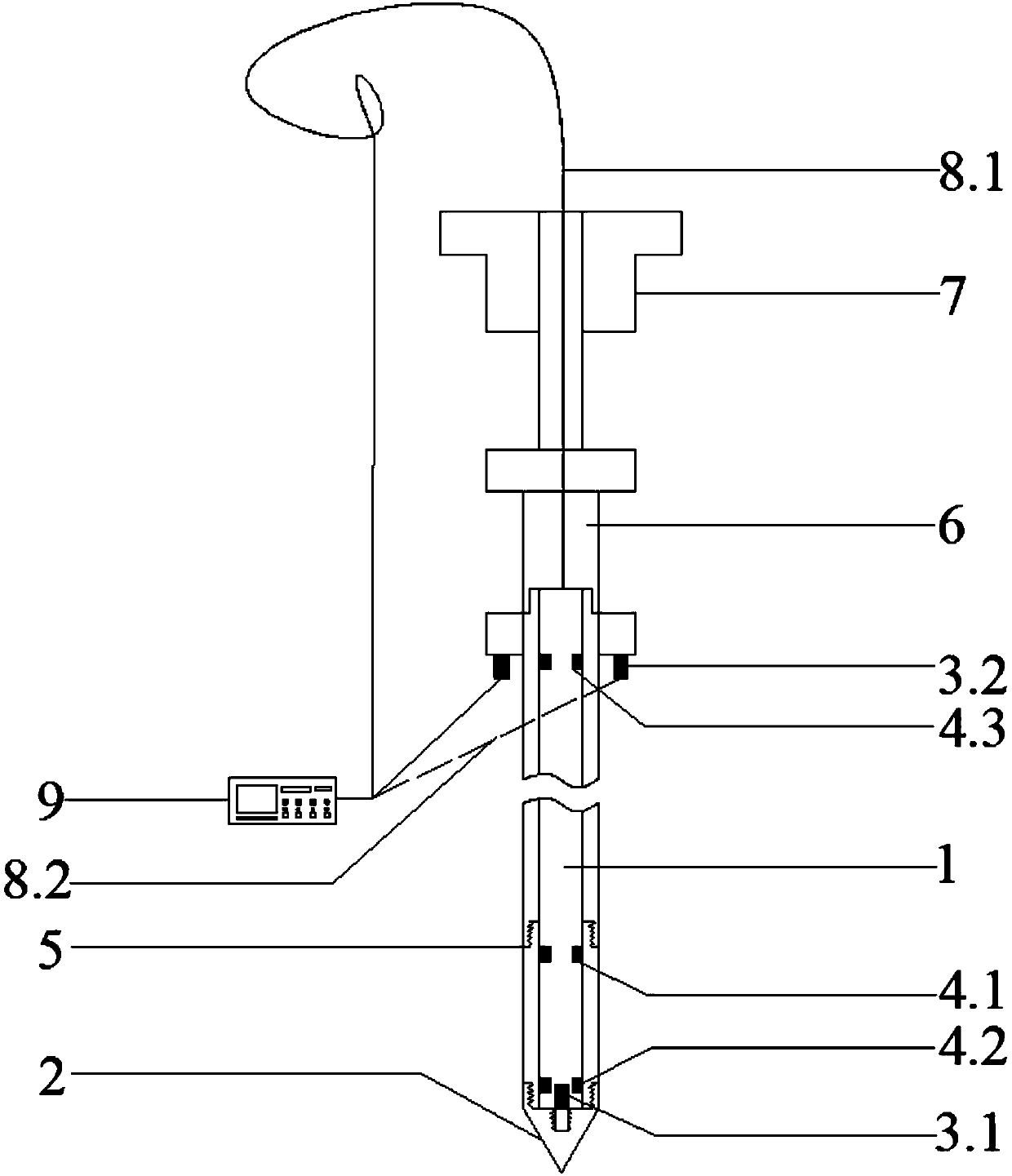

[0013] A power penetrometer that automatically considers energy correction and dynamic response of the present invention includes that the penetrometer includes a drop weight 7, a stabilized fin 6, and a probe rod 1 in order from top to bottom; wherein, the upper end of the probe rod 1 and the stabilized fin 6 are connected, the third strain gauge 4.3 is symmetrically installed on the inner wall of the upper end of the probe rod 1, and the second acceleration sensor 3.2 is symmetrically arranged at the lower end of the stabilizer fin 6. The first acceleration sensor 3.1 and the second strain gauge 4.2 are arranged inside, the friction sleeve 5 is arranged outside the probe rod 1, and the first strain gauge 4.1 is arranged on the inner wall of the top of the friction sleeve 5; The drop hammer 7, the electrical signals of the sensors of the penetrometer are transmitted to the data acquisition analyzer 9 by the coaxial cable 8.1 and the signal cable 8.2.

[0014] The outer diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com