Main-cable sealing structure of submersible electric pump

A cable sealing and sealing structure technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of sealing and waterproof ability affecting the reliability of submersible motors, affecting the reliability of sealing surfaces, and burning stator coils. Low cost and the effect of solving the problem of water inflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

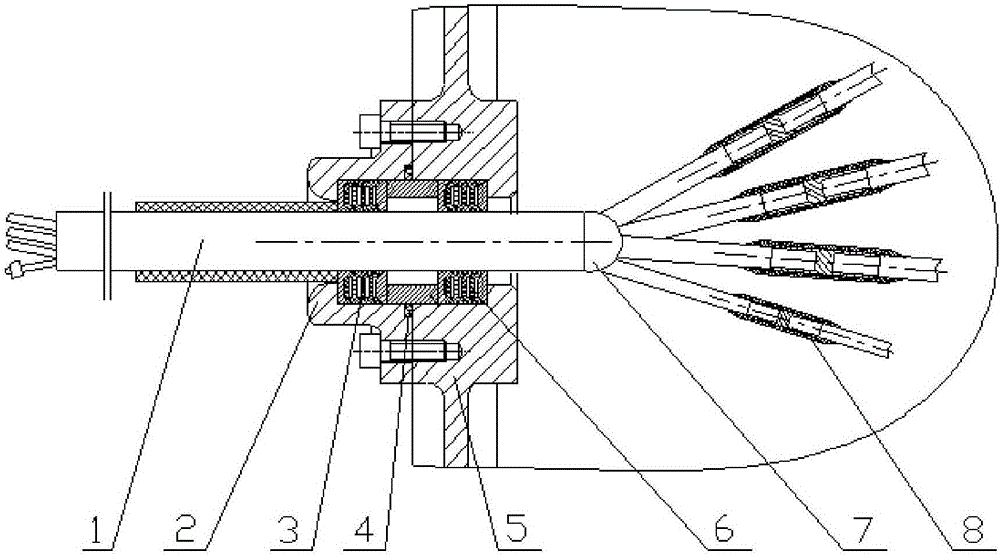

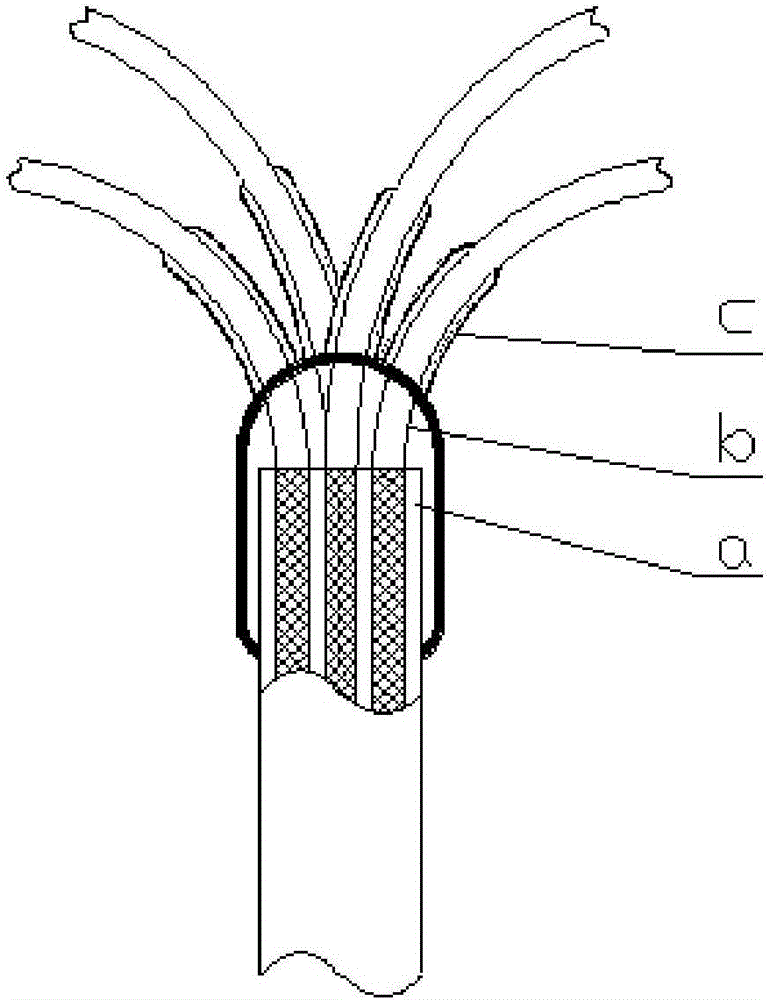

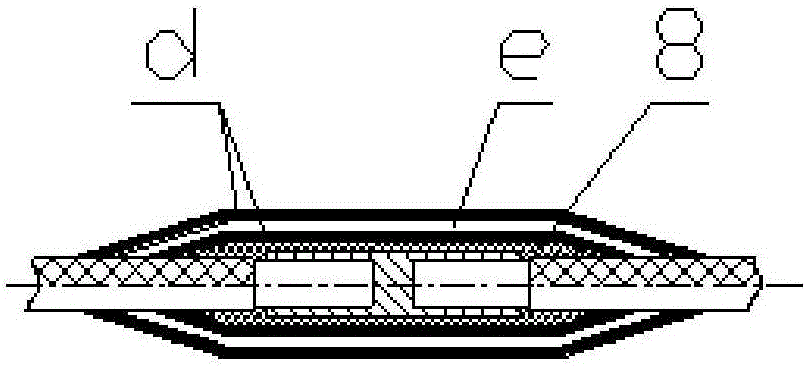

[0016] see figure 1 , a submersible pump main cable sealing structure, including a main cable 1, a cable gland 2 and a junction box cover 5, the cable gland 2 fixes and compresses the main cable 1 in the outlet hole of the junction box cover 5, the main There is a first rubber cup sealing ring 3 between the cable 1 and the cable gland 2. In addition to the sealing performance, it also has the function of fixing the main cable 1 and preventing the shaking of the main cable 1 caused by the impact of water flow. The cable gland 1 and the junction box The joint surface of the cover 5 is provided with an O-shaped sealing ring 4 to prevent water from entering from the joint surface. A second leather cup sealing ring 6 is provided between the main cable 1 and the outlet hole of the junction box cover 5 to ensure that the above two The failure of the sealing structure prevents the incoming water from entering the inner cavity of the motor; the bifurcation of the core of the main cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com