End hole processing jig and clamping method of acceleration motor shell

A technology for accelerating motors and shells, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor versatility, and achieve the effect of simple and practical structure, convenient location, and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

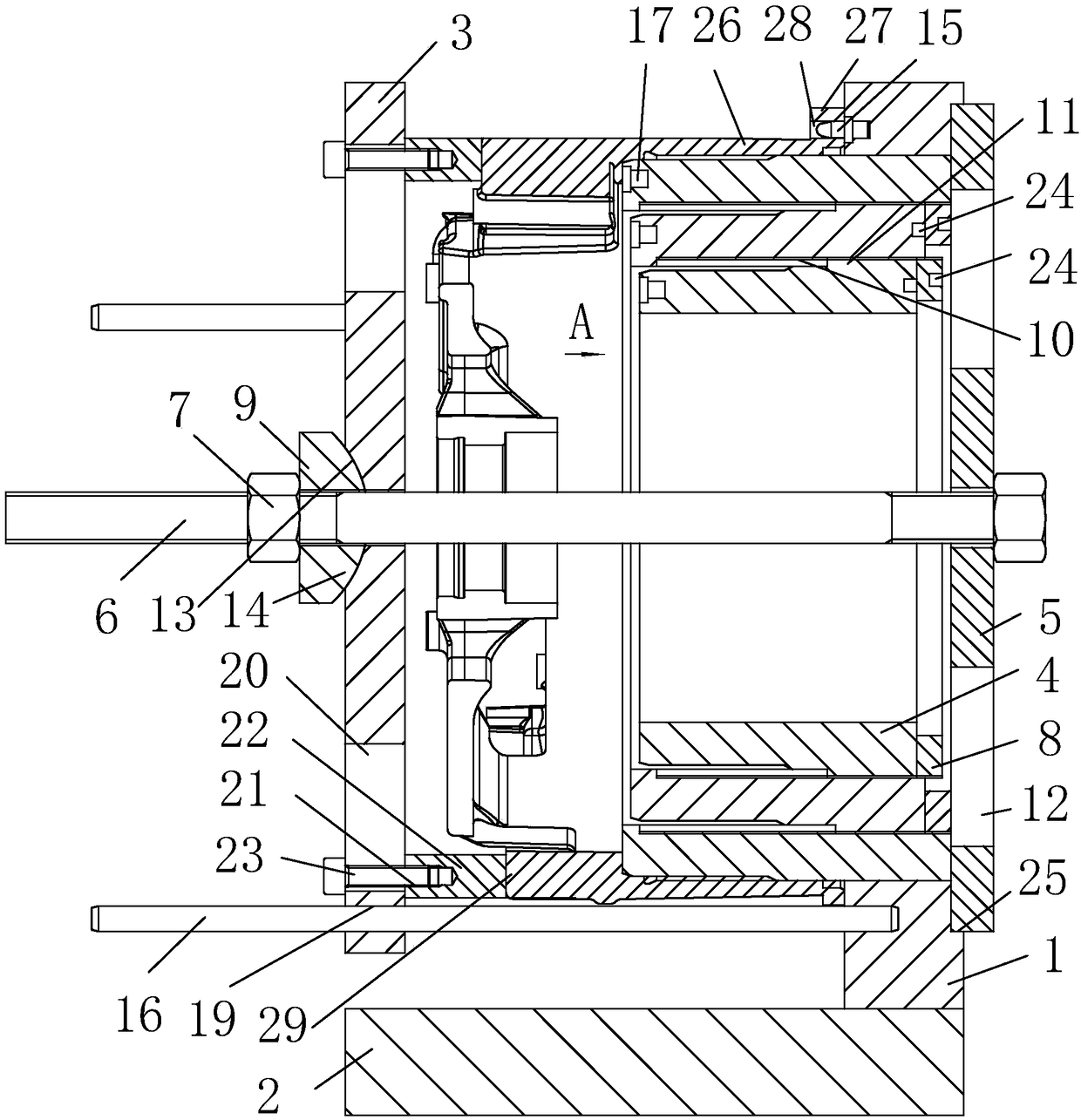

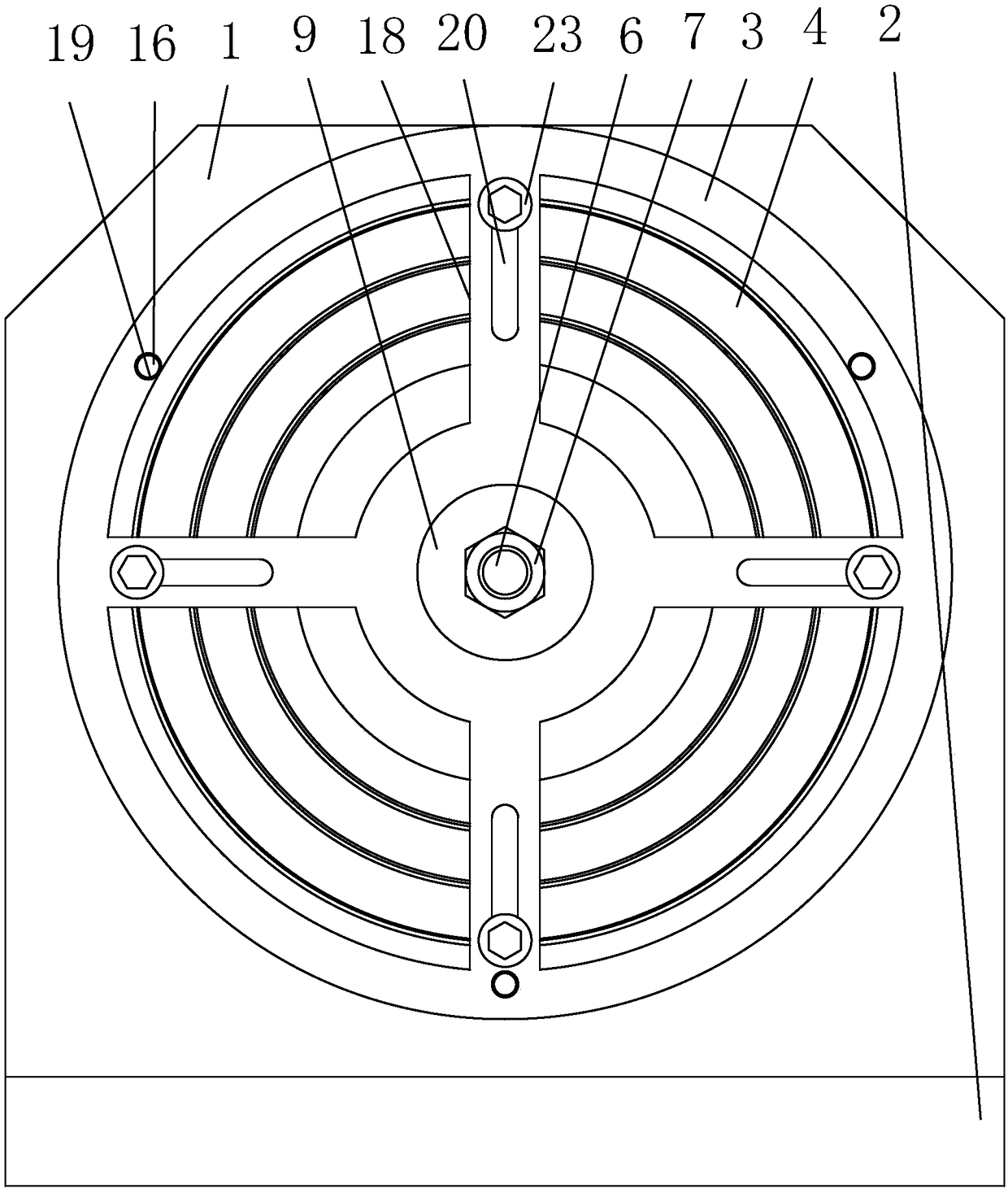

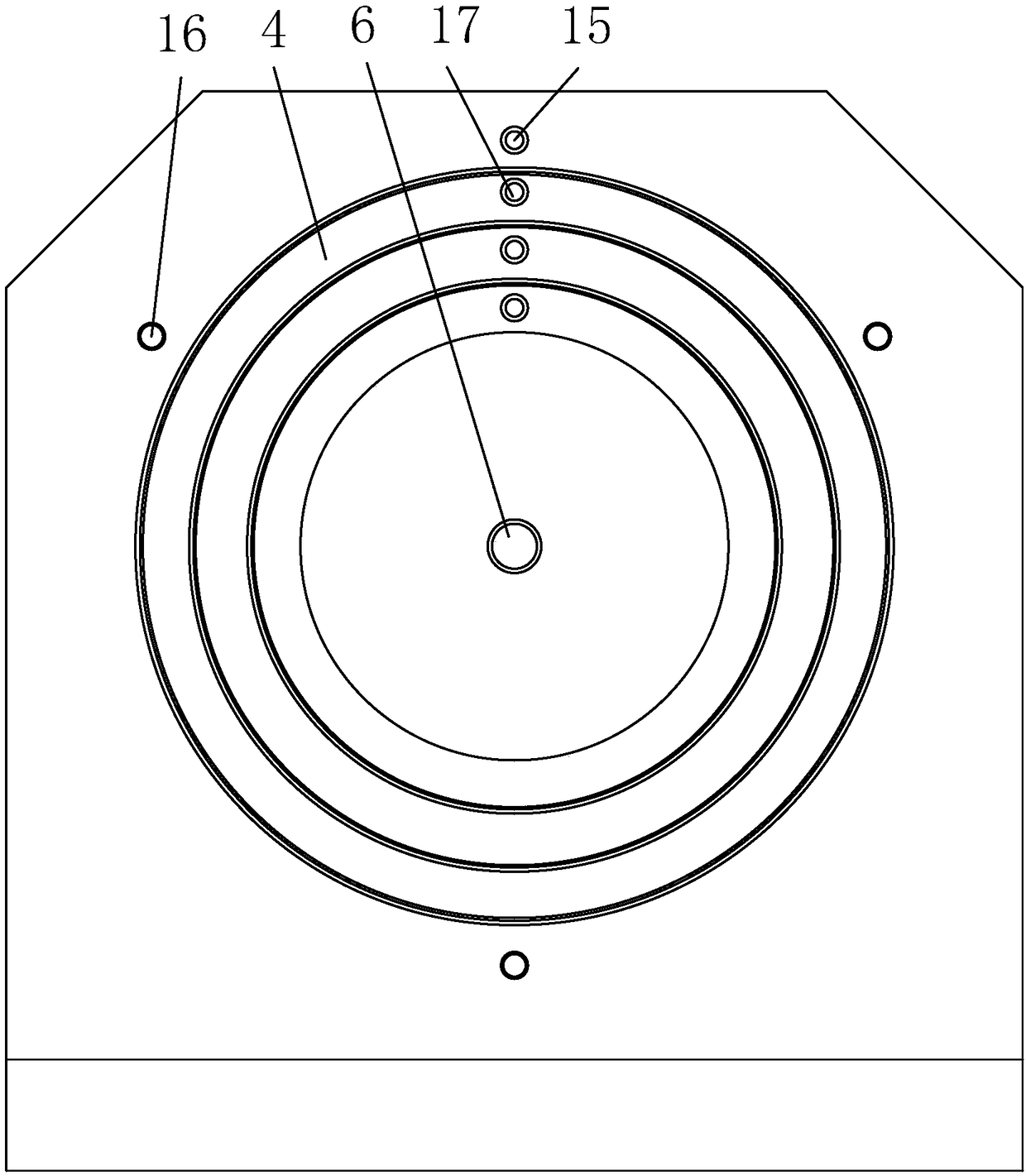

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] as attached figure 1 , attached figure 2 , attached image 3 Shown: a jig for processing the end hole of the acceleration motor housing, including: a base 2 with a vertical plate 1, a front pressure plate 3 with four pressing components at the rear end, and three coaxial positioning cores Cylinder 4, rear pressure plate 5, bolt 6 and fixing nut 7, locking ring 8 whose number is one less than the number of positioning core barrel 4, washer 9, positioning assembly.

[0022] The vertical plate 1 is sleeved outside the outermost positioning core barrel 4 and is screwed to the rear of the outermost positioning core barrel 4; the screw rod of the bolt 6 passes through the rear pressure plate 5, the positioning core barrel 4 and the front pressure plate 3 And be threadedly connected with fixing nut 7; Two adjacent positioning core barrels 4 are positioned at outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com