Front wheel connection disc of dune buggy

A connecting disc and front wheel technology, which is applied to bicycle accessories, axle suspension devices, transportation and packaging, etc., can solve the problems of the radial displacement of the hub and the connecting disc, reducing the driving stability of the front wheel, and increasing the difficulty of assembly. Achieve the effect of not easy to move, eliminate jumping, and reduce shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

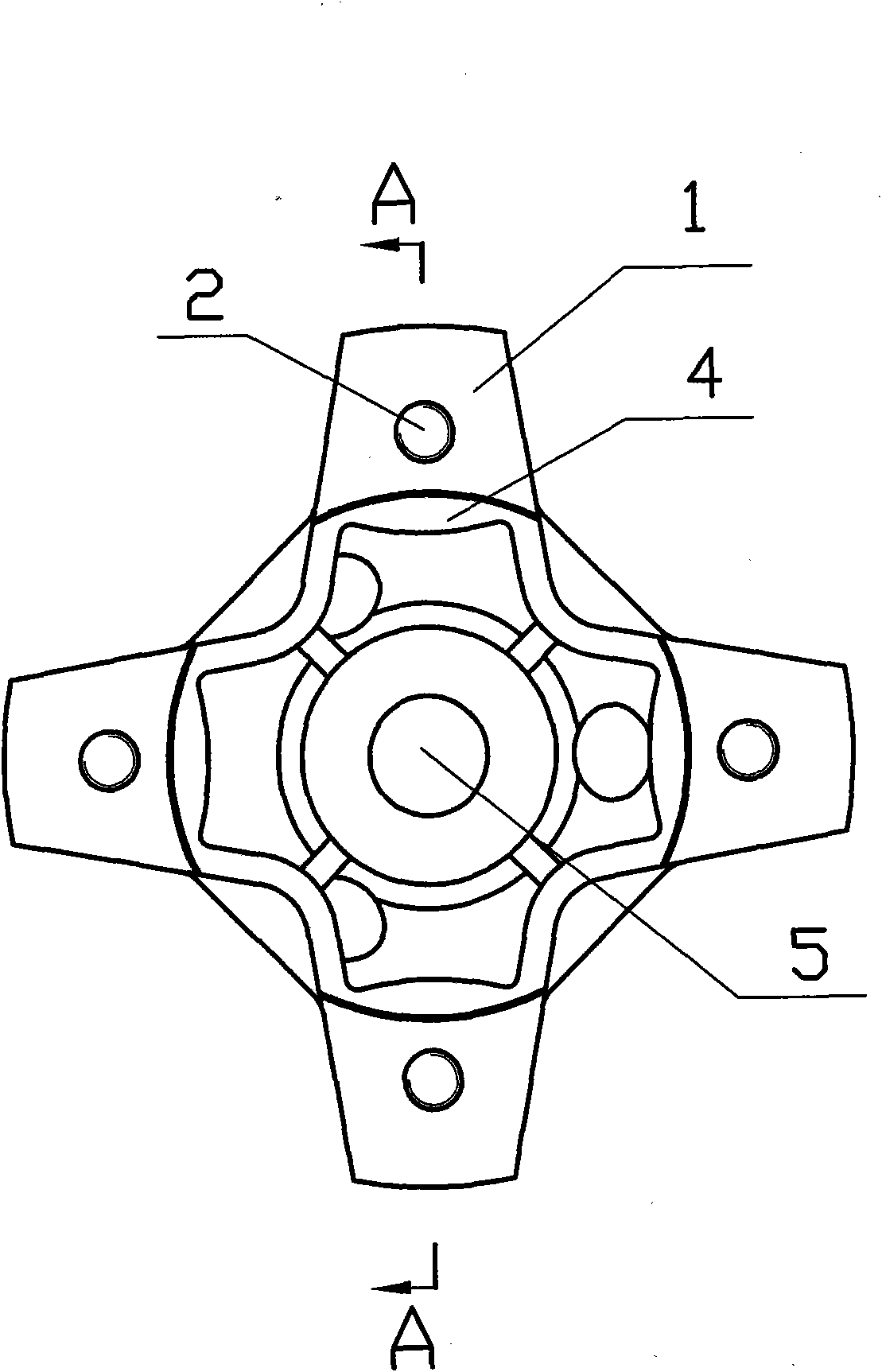

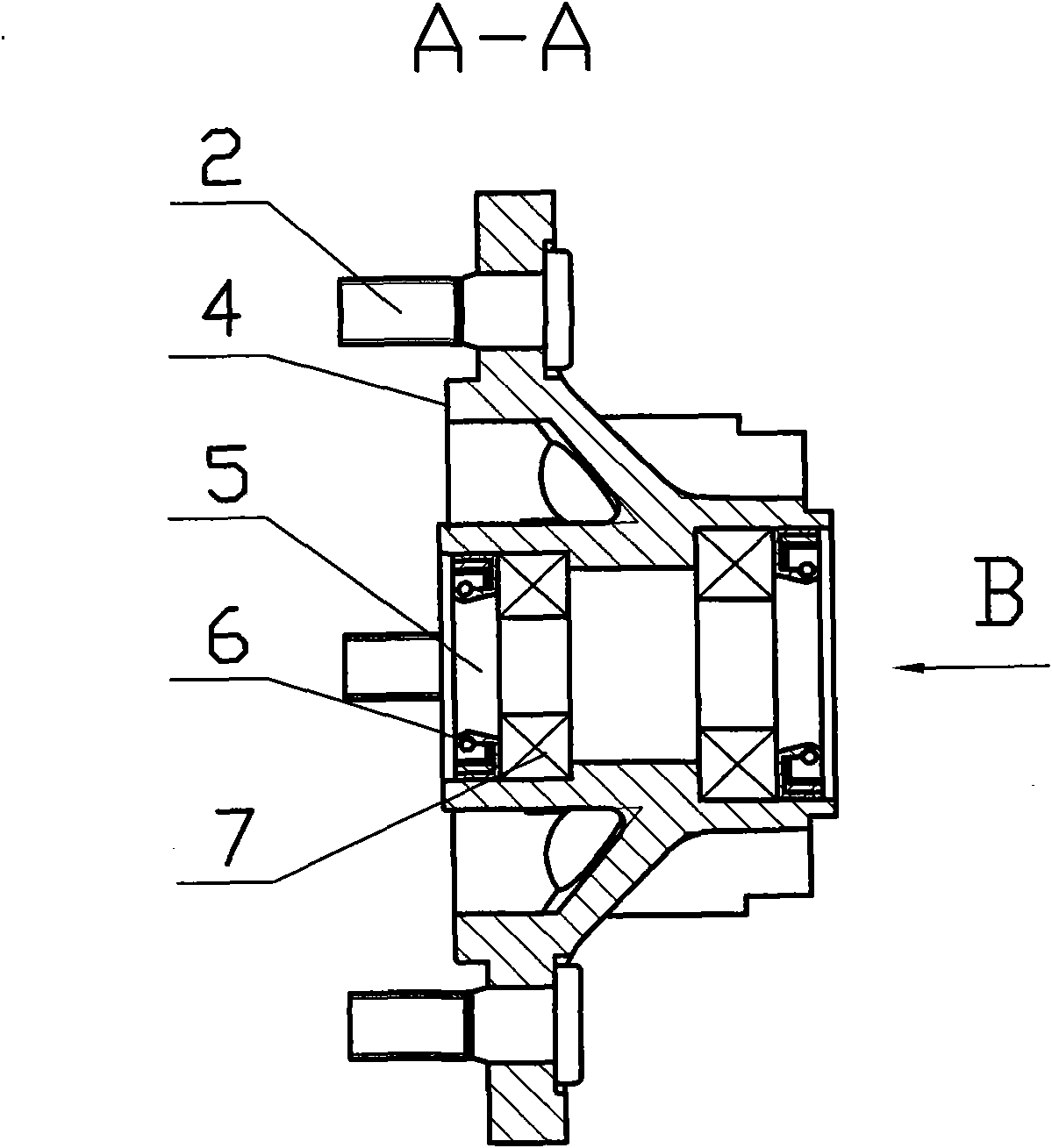

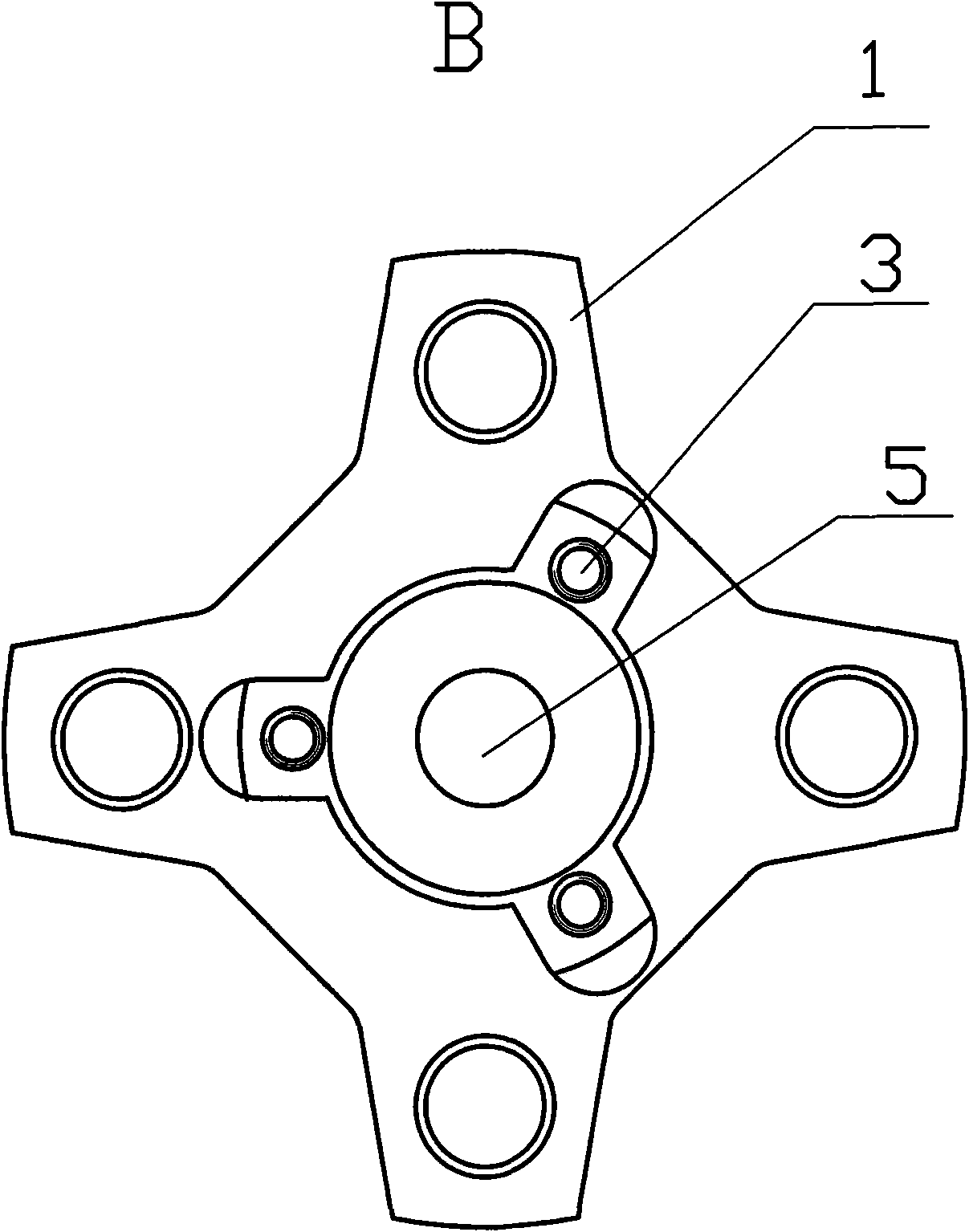

[0012] refer to Figure 1 to Figure 4 , the connecting disc is provided with a shaft hole 5 cooperating with the steering knuckle shaft, the shaft hole is provided with a bearing 7 supporting the steering knuckle shaft, and an oil seal 6 is provided adjacent to the bearing along the axial end connected with the hub. The axial end of the connection plate 6 for connecting with the hub is symmetrically provided with four radially extending installation parts 1, and the installation parts are respectively provided with studs 2, and the studs 2 are connected with the hub in the support direction on the installation parts. On one side of the axial end of the shaft, four studs 2 are evenly distributed around the shaft hole. The other axial end of the connection plate is provided with three threaded holes 3, and the threaded holes 3 are evenly distributed around the shaft hole. The axial end face connected between the connecting disc and the hub is provided with a positioning boss 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com