Ceramic thrust bearing assembly and water-lubricated screw compressor

A technology of screw compressor and thrust bearing, applied in the direction of bearing components, rigid brackets of bearing components, bearings, etc., can solve the problems of expensive ceramic bearing materials, high brittleness of ceramic bearings, economic losses, etc., so as to reduce the risk of damage and improve the Service life and the effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

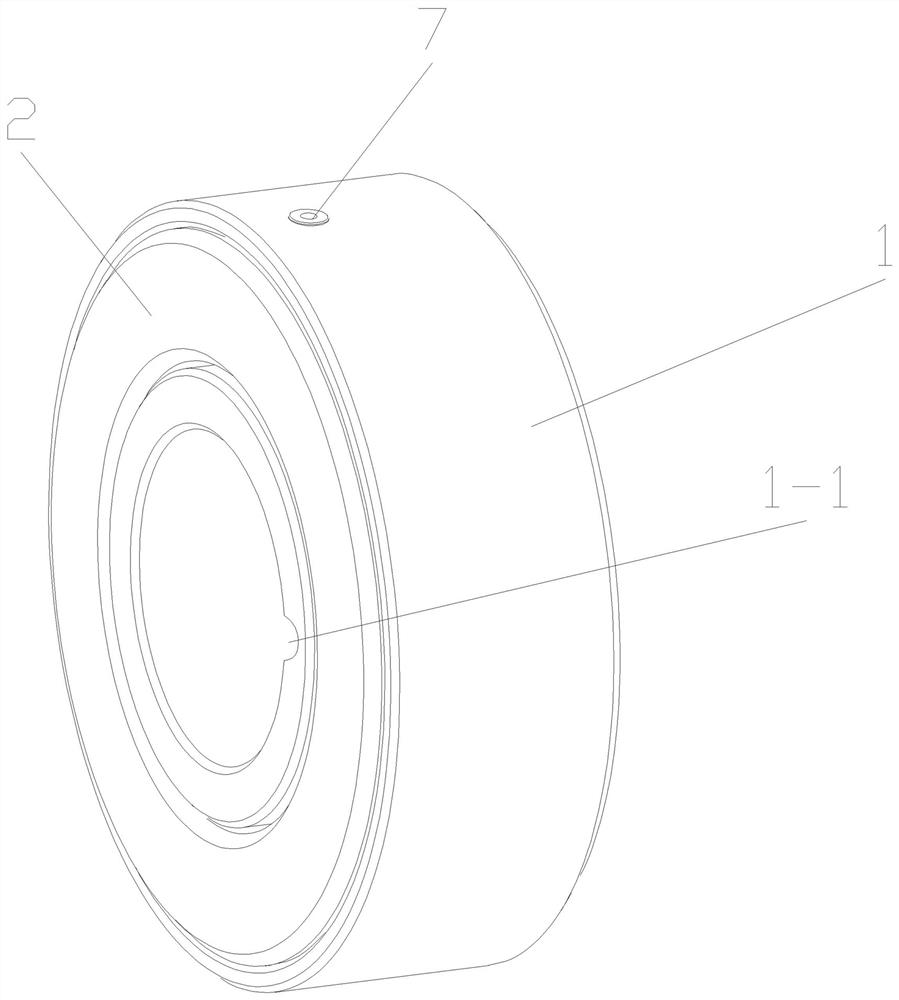

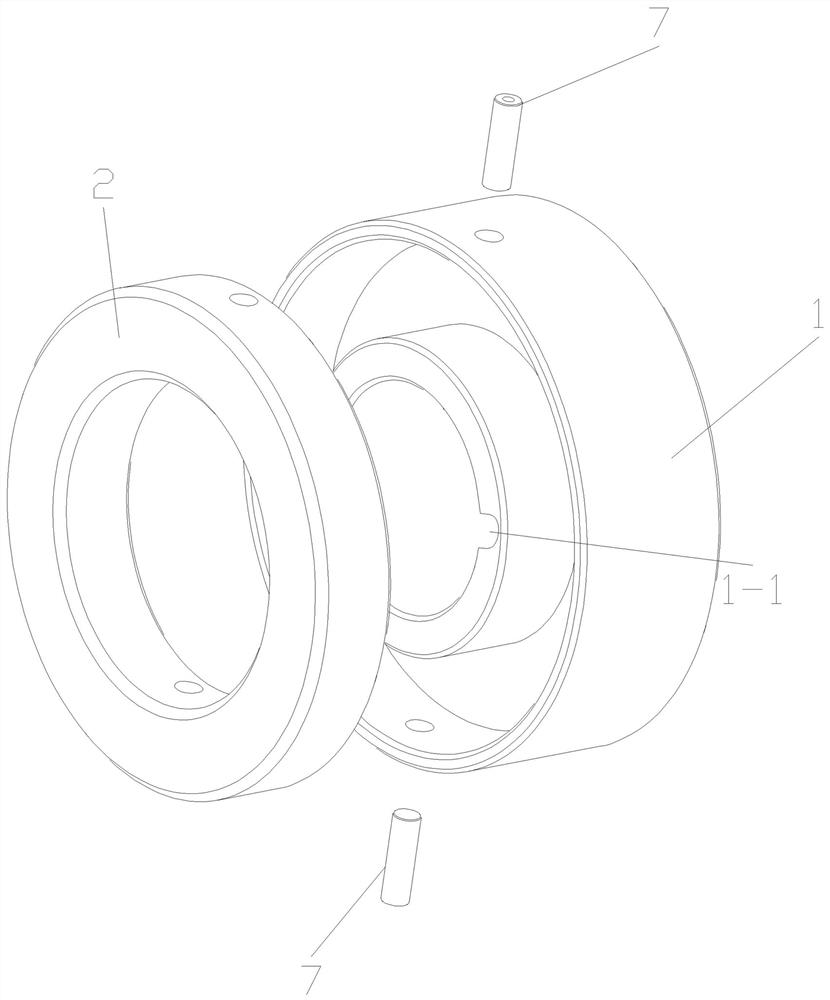

[0024] Such as figure 1 with figure 2 As shown in , the ceramic thrust bearing assembly of the present invention includes a thrust bearing housing 1, a ceramic thrust bearing 2 and two thrust bearing positioning pins 7, and the ceramic thrust bearing 2 is ceramic made of silicon carbide, zirconia, silicon nitride and other materials Bearing, thrust bearing housing 1 is made of stainless steel and other materials that are not easily corroded by water. Both thrust bearing housing 1 and ceramic thrust bearing 2 are of annular structure, and thrust bearing housing 1 is provided with an annular groove for installing ceramic thrust bearing 2. 2 is limited between the side wall of the inner ring and the side wall of the outer ring of the annular groove, one end surface and two annular side walls of the ceramic thrust bearing 2 are wrapped in the annular groove, and the working end surface of the ceramic thrust bearing 2 is convex Out of the annular groove, the thrust bearing seat 1...

Embodiment 2

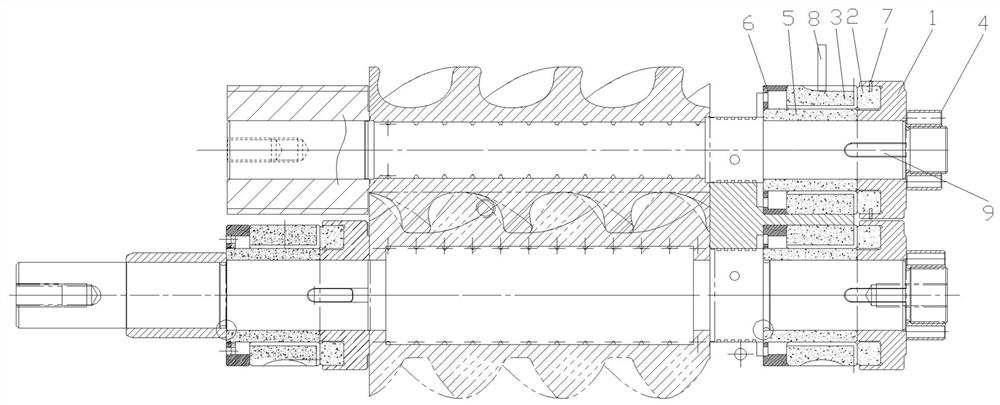

[0026] Such as image 3As shown in , the water-lubricated screw compressor of the present invention includes a compressor host, a screw rotor is arranged in the cylinder of the compressor host, and a bearing hole is arranged on the casing of the compressor host, and the bearing hole is provided with a The ceramic thrust bearing assembly described in Example 1 also includes a ceramic bushing 3, a ceramic bushing 5, and a spring mounting seat 6. A wave spring is arranged in the spring mounting seat 6, and the ceramic bushing 5, the ceramic bushing 3, and the ceramic thrust bearing 2 They are all made of ceramic material. In this embodiment, silicon carbide material is used, and zirconia material can also be used; the spring mounting seat 6, the ceramic bushing 5, and the thrust bearing seat 1 are all sleeved on the screw rotor, and the spring mounting seat 6 is limited. On the inner side of the bearing hole, the inner side of the ceramic bushing 5 is also provided with a keyway,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com