Electromagnetic actuating unit

An executive unit and electromagnetic technology, applied in circuits, engine components, machines/engines, etc., can solve problems such as high cost and high assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

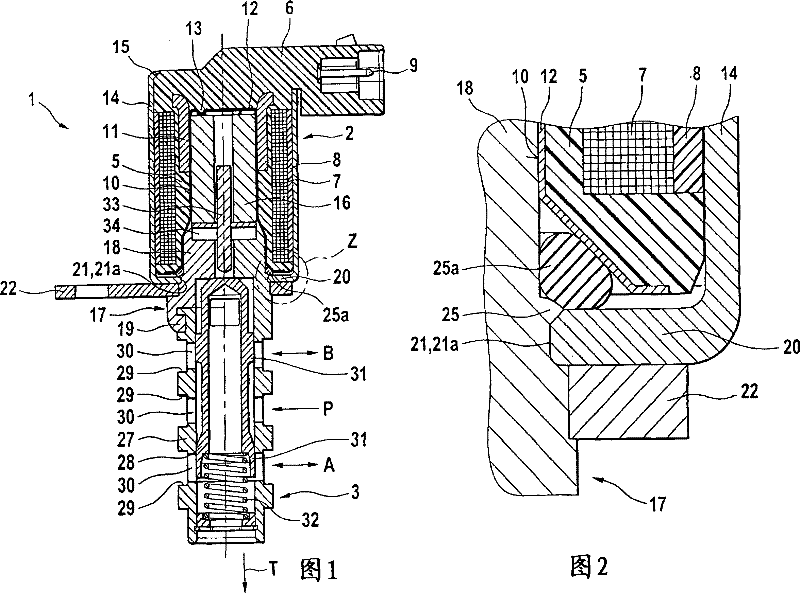

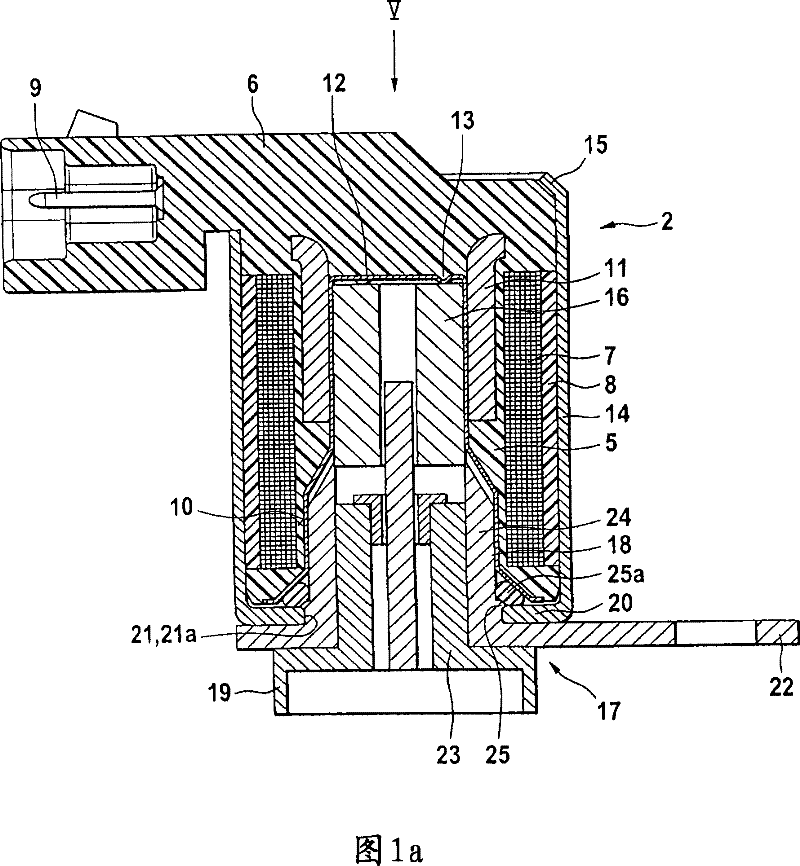

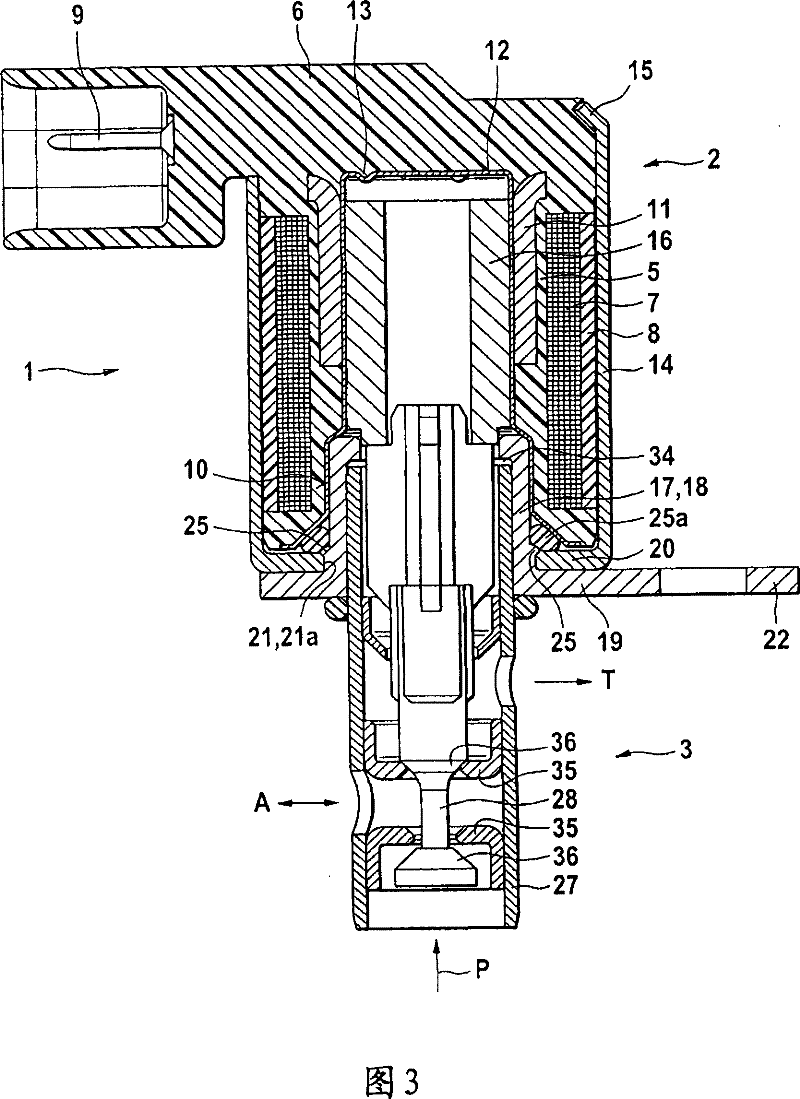

[0025] figure 1 A first embodiment of the electromagnetic actuating unit 2 according to the invention is shown, for example as a directional control valve 1 designed as a 4 / 3-way proportional valve. The reversing valve 1 has an electromagnetic actuator unit 2 and a valve section 3 .

[0026] The electromagnetic actuator unit 2 has a coil carrier 5 and a connecting element 6 integrated therewith. The bobbin 5 carries a coil 7 consisting of several windings of a suitable wire. The radially outer circumferential surface of the coil 7 is surrounded by a sleeve-shaped material layer 8 which consists of a non-magnetizable material. The material layer 8 can consist, for example, of a suitable plastic and is sprayed onto the wound coil 7 . A conductive plug-in connector 9 is accommodated in the connecting element 6 , through which the coil 7 can be supplied with current.

[0027] The coil carrier 5 is designed with an essentially cylindrical blind-hole recess 10 which is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com