Parallel multi-rod synchronous drive railing lifting mechanism

A technology of synchronous drive and lifting mechanism, applied in the direction of lifting devices, etc., can solve problems such as maintenance troubles, small number of railings, and reduced work efficiency, and achieve the effects of simplifying the hydraulic system, improving safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

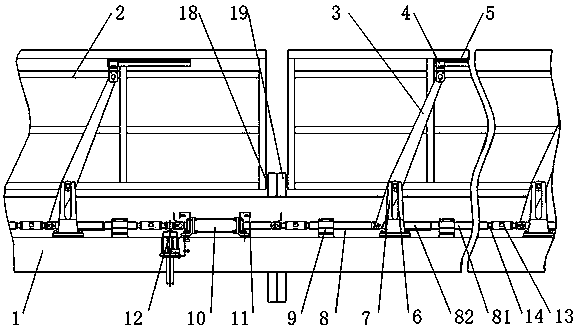

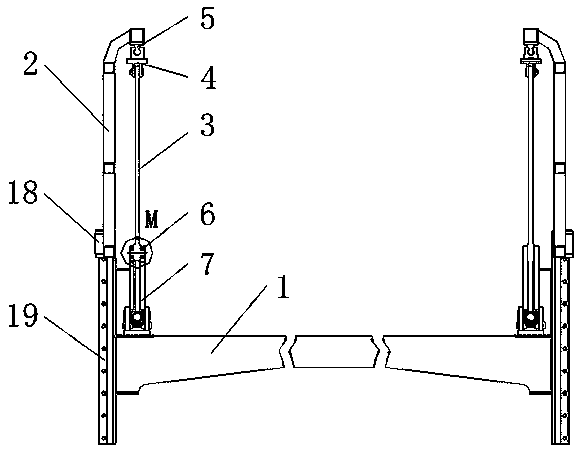

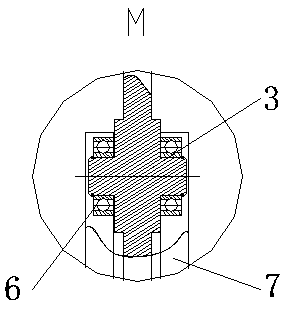

[0018] Such as Figure 1 to Figure 4 The shown parallel multi-rod synchronous driving railing lifting mechanism includes a lifting platform 1, and a plurality of railings 2 are arranged on both sides of the lifting platform 1, and a lifting rod 3 is arranged between the railing 2 and the lifting platform 1, and the lifting rod The upper end of 3 is connected with the upper slide rail 5 that is arranged on railing 2 upper ends through upper slide block 4; The two sides of the middle and lower part of described elevating rod 3 are symmetrically provided with bearings 6, and symmetrically fixed with The U-shaped slide rail 7 used in conjunction with the bearings 6 on both sides; the lower end of the lifting rod 3 is hinged with a pull rod 8 horizontally arranged on the lifting platform 1, and the lifting platform 1 is provided with a location for limiting the direction of movement of the pull rod 8 Block 9; the pull rod 8 is connected with a two-way power cylinder 10 whose motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com