Construction method of deep beam steel support in transfer layer

A construction method and transfer layer technology, which is applied in the fields of architecture, building structure, and building materials processing, etc., can solve problems such as the difficulty in flexibly adjusting the installation height of stirrups or support frames, difficulty in meeting on-site construction requirements, and reuse of difficult-to-support materials. , to achieve the effect of improving installation quality and work efficiency, high support construction efficiency, and saving time and effort in layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

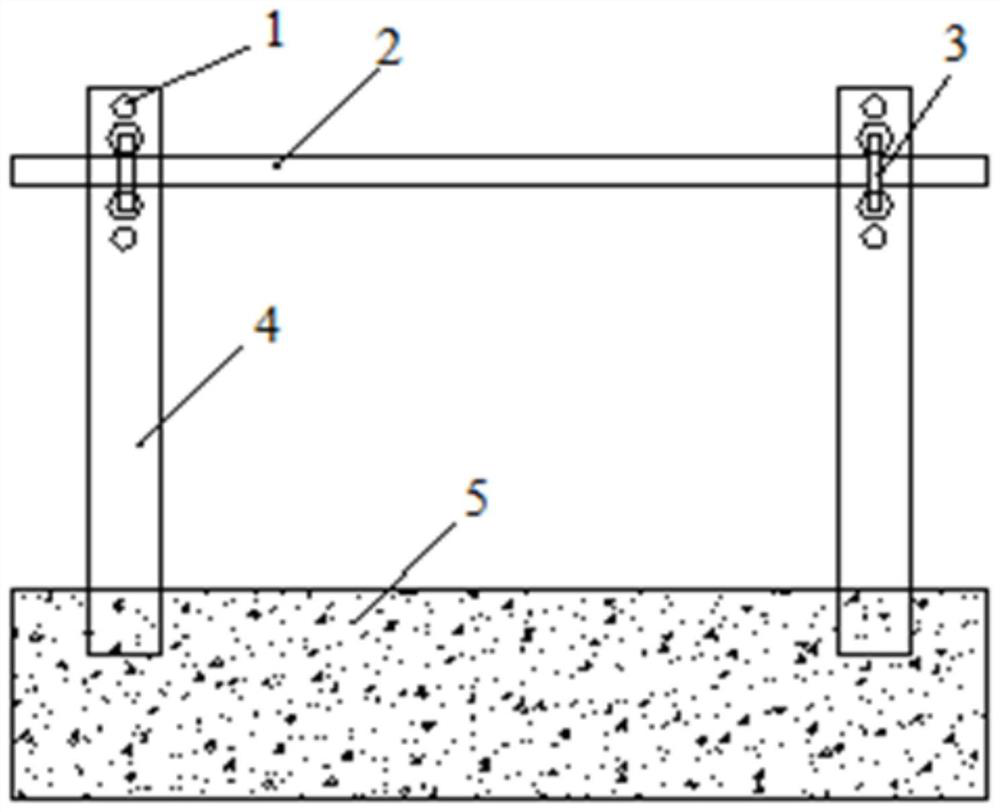

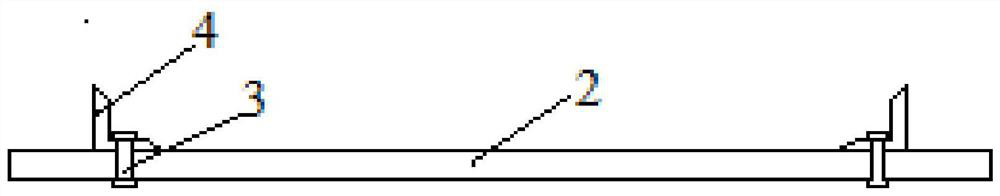

[0035] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

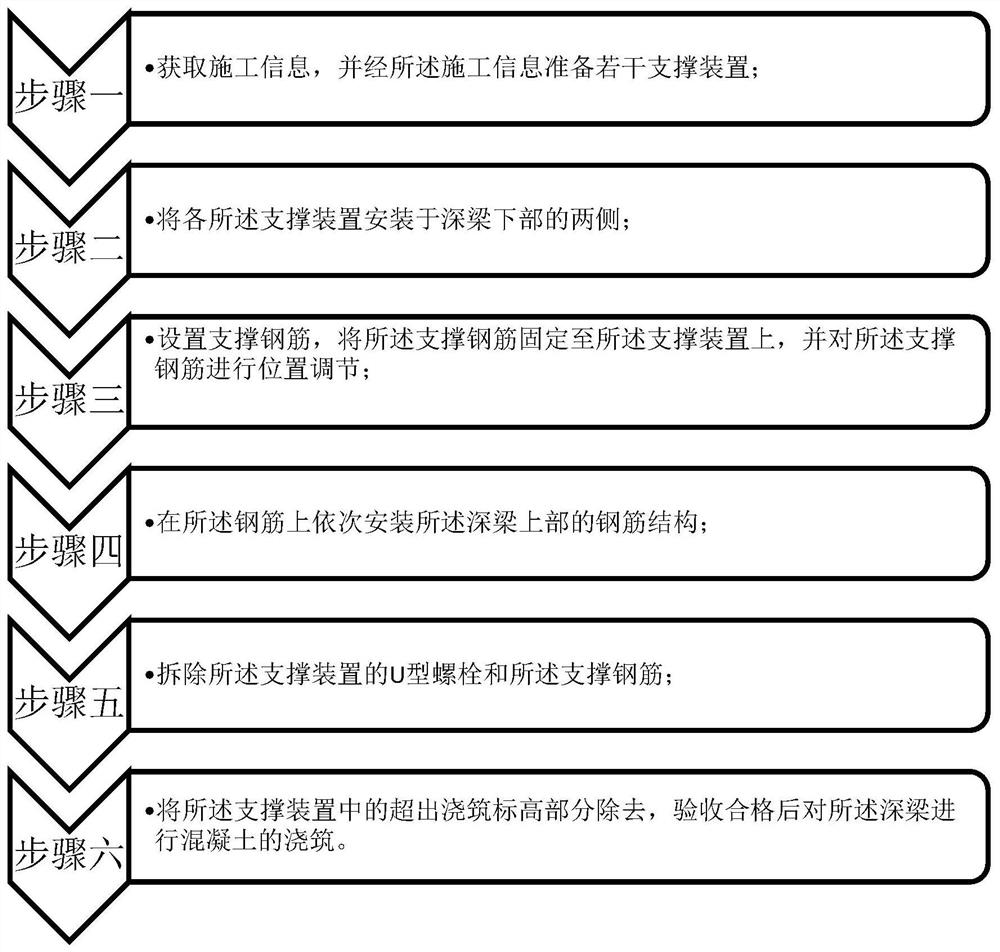

[0036] refer to Figure 1 to Figure 3 , the present application provides a construction method for steel bar support of converted story depth beams, including:

[0037] Step 1. Obtain construction information, and prepare several supporting devices according to the construction information.

[0038] Step 2, installing each supporting device on both sides of the lower part of the deep beam.

[0039] Step 3: setting the supporting steel bar 2, fixing the supporting steel bar 2 on the supporting device, and adjusting the position of the supporting steel bar 2.

[0040] Step 4, sequentially installing the reinforcement structure on the upper part of the deep beam on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com