Tool structure for machining end faces of high-concentricity shaft parts

A technology for shaft parts and end face processing, applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problem of inability to ensure the concentricity of parts and clamping parts, pinching or wear of shaft parts, affecting parts processing Quality and other issues, to achieve the effect of saving time and effort in layout, improving installation time, improving production efficiency and progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described below in conjunction with the drawings.

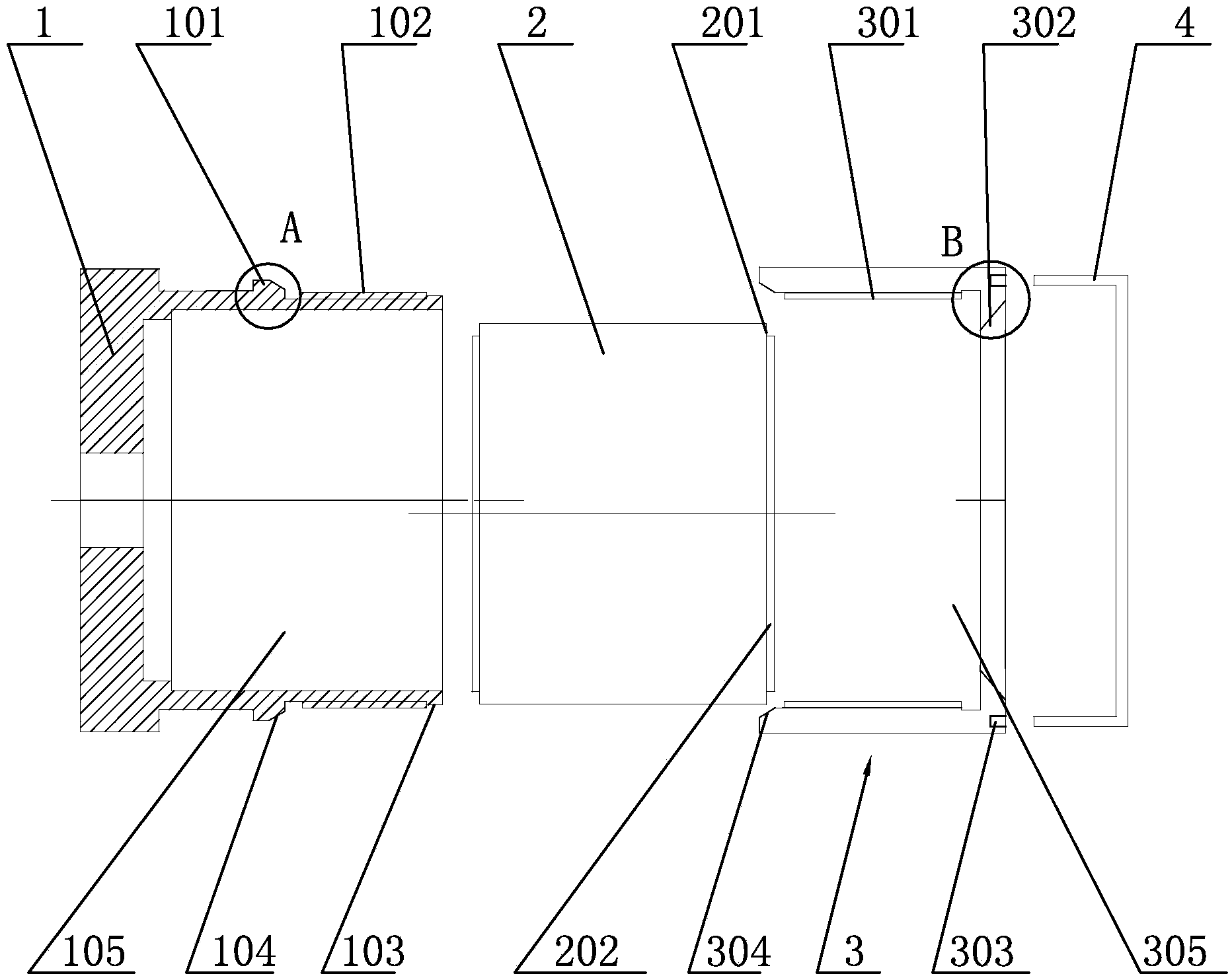

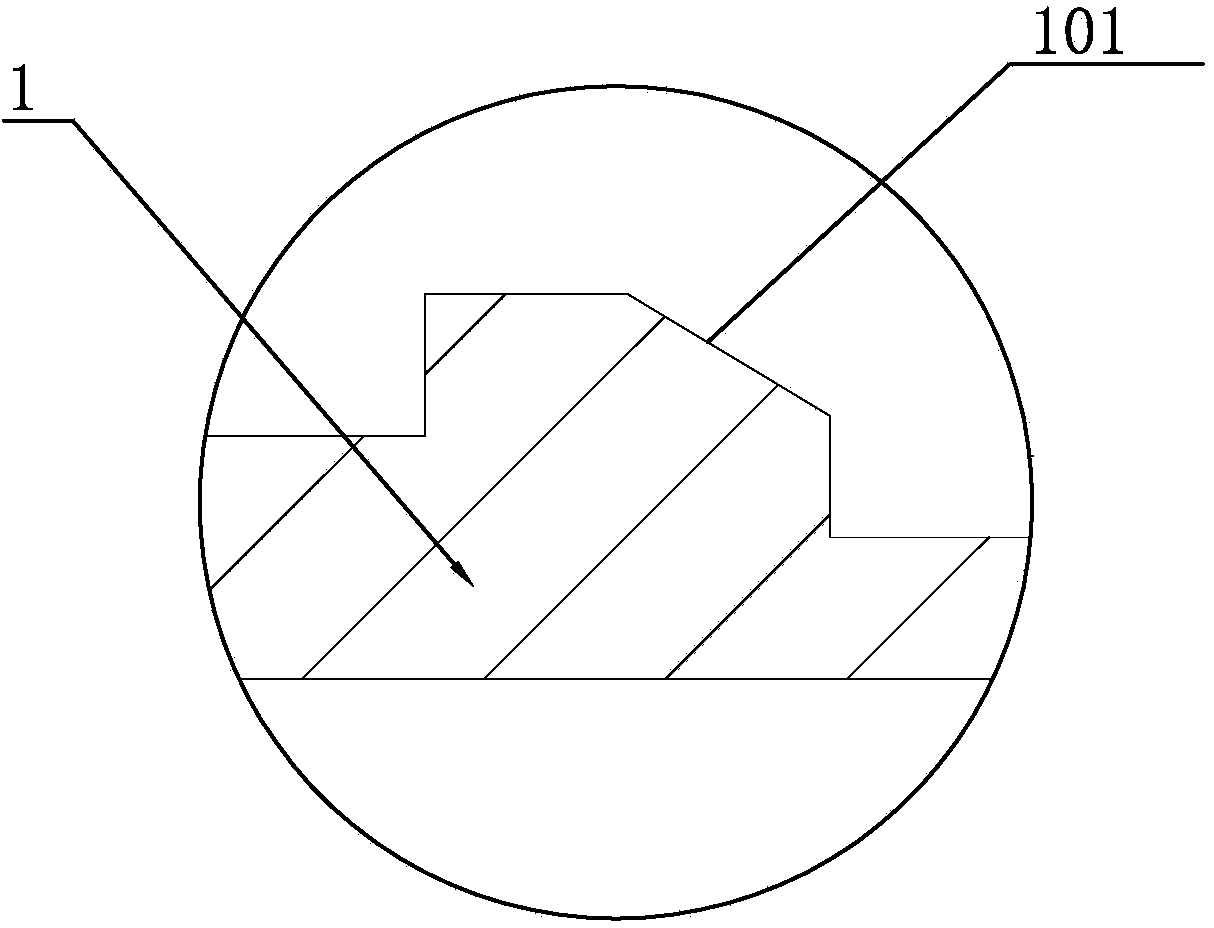

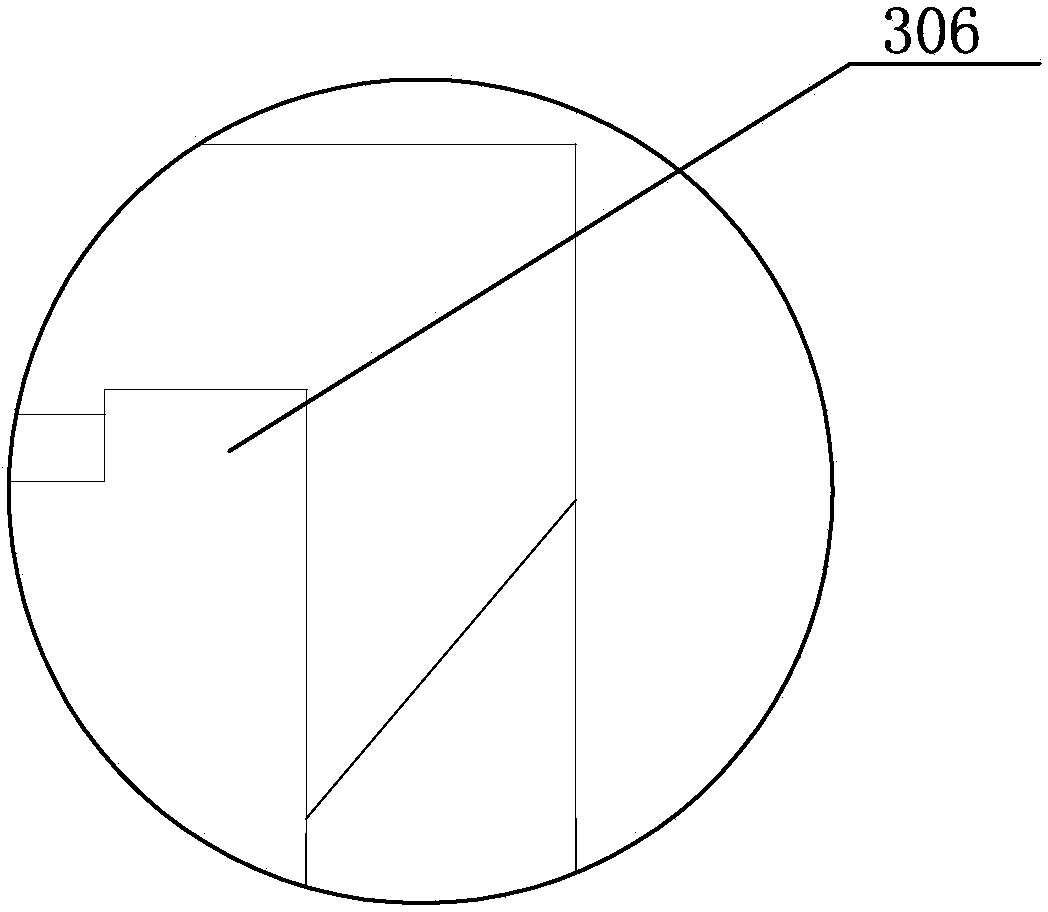

[0018] Such as figure 1 As shown, the present invention includes a positioning sleeve 1, a counterbore 105 for fitting shaft parts 2 is opened in the middle of the positioning sleeve 1, and an external thread 102 and a connecting flange 101 are provided on the outer periphery of the positioning sleeve 1, such as figure 2 As shown, a first inclined surface 104 is provided on the connecting flange 101. Such as figure 1 As shown, the rotating sleeve 3 is threadedly connected with the positioning sleeve 1. A groove 305 is opened in the middle of the rotating sleeve 3, and an internal thread 301 and a second inclined surface 304 are arranged in the groove 305, and a through hole 302 is also opened on the rotating sleeve 3. The through hole 302 is a tapered hole. An arc-shaped groove 303 is also opened on the rotating sleeve 3 so that the end of the rotating handle 4 fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com