Manufacturing method of electric vehicle AC charging device considering maintenance service

A technology for AC charging and electric vehicles, applied in geometric CAD, design optimization/simulation, special data processing applications, etc., can solve the problems of lack of basis for manufacturing and difficulty in obtaining modular design schemes for AC charging devices with maintenance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

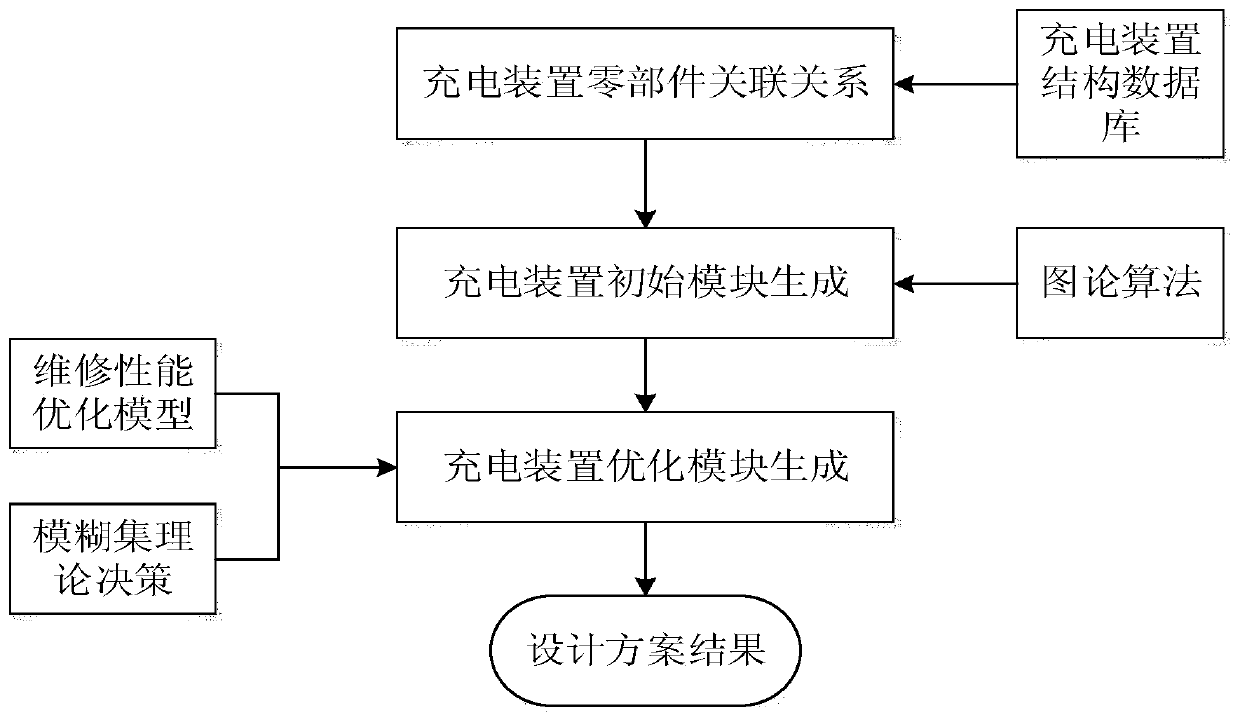

[0041] A method for manufacturing an electric vehicle AC charging device considering maintenance services, characterized in that it includes the following steps:

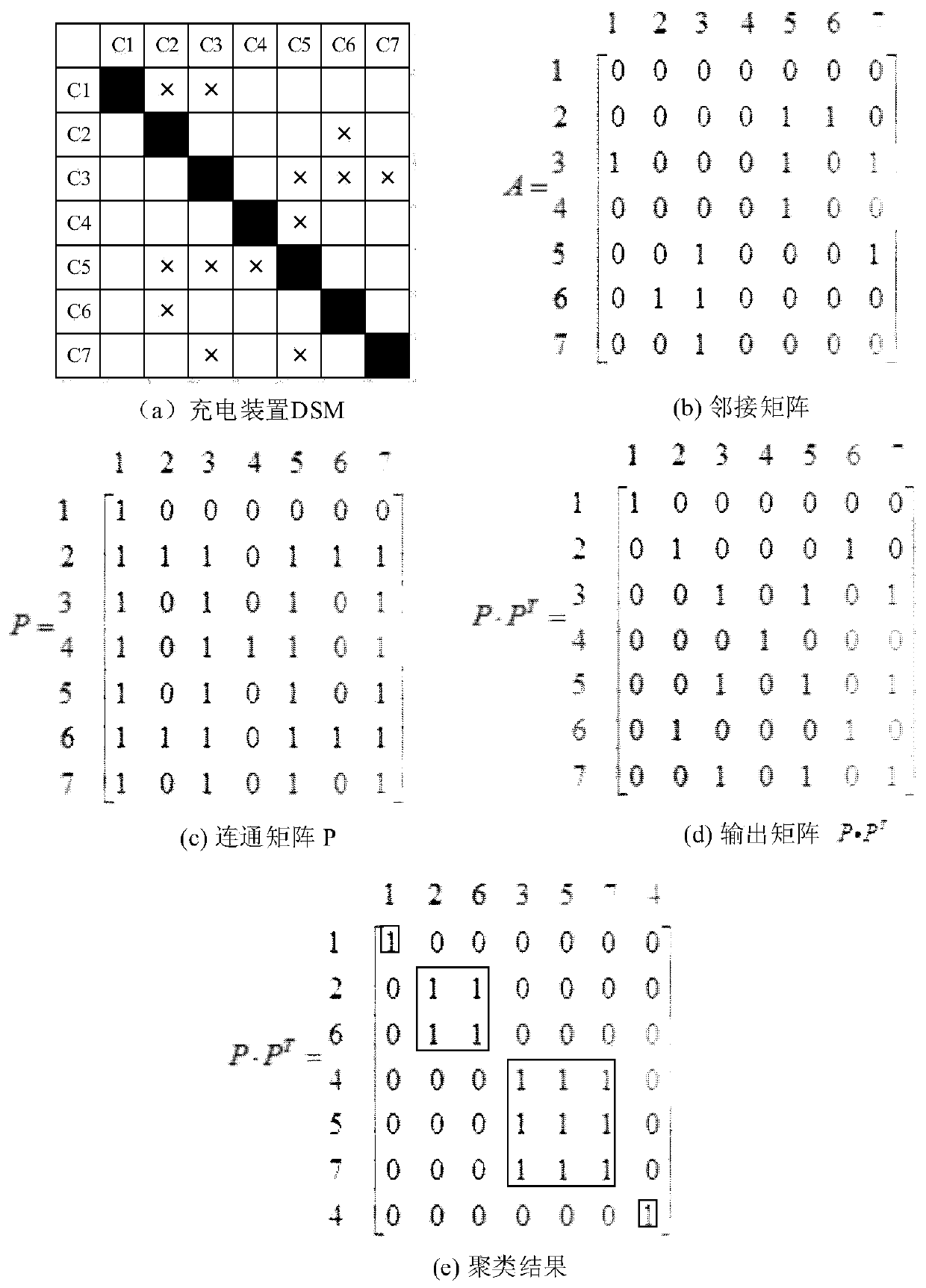

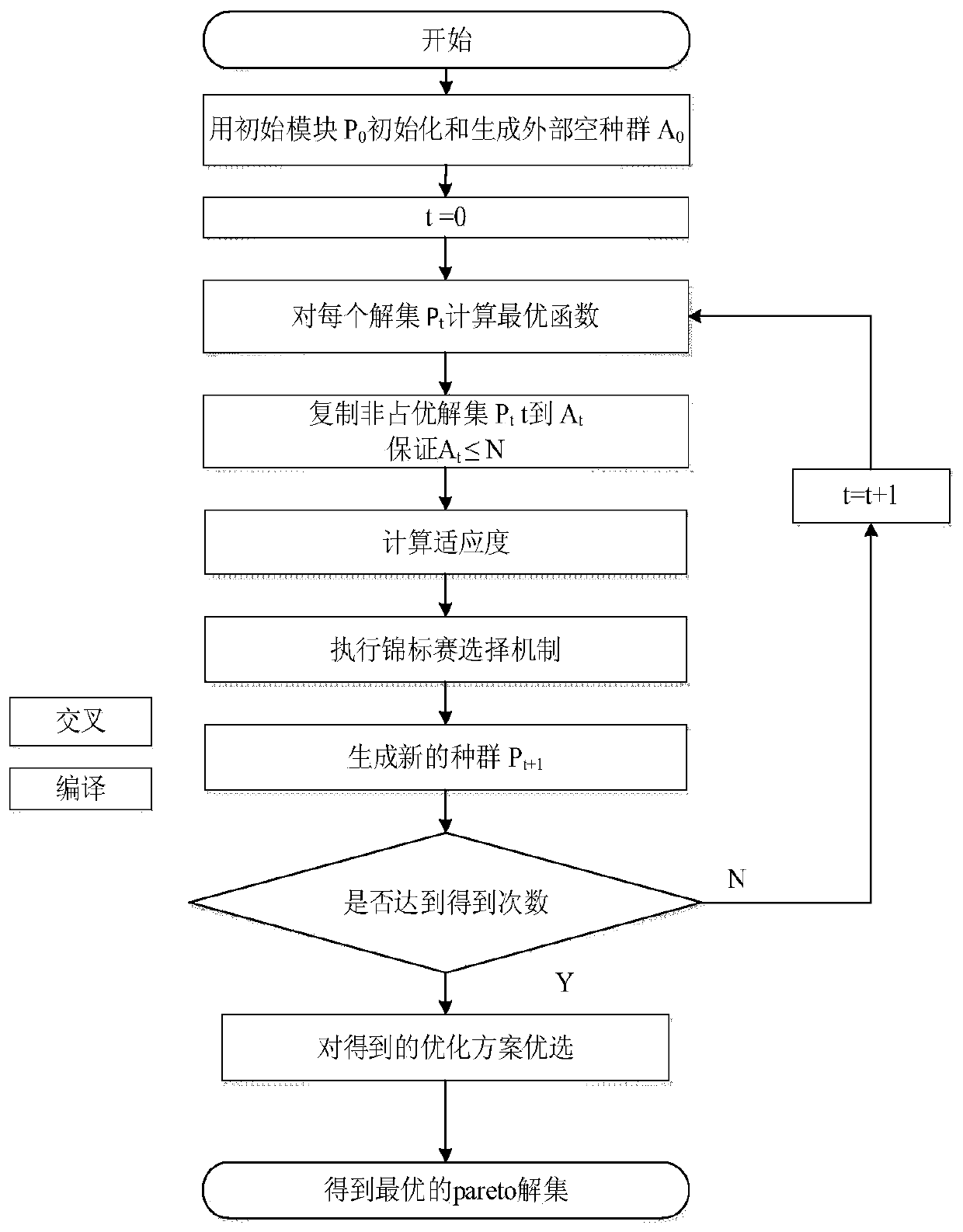

[0042] Step 1: According to the analysis of the structural relationship between the parts of the electric vehicle AC charging device, the design structure matrix model of the AC charging device is established, and the graph theory method is used to divide the AC charging device for the first time, and the corresponding modular initial scheme is obtained; in the step 1 Among them, based on the B / S architecture, the relationship between the components of the charging device is analyzed, and the after-sales maintenance data is submitted through the Web page, and the maintenance characteristic indicators including cost and life cycle are extracted through the parser, and the maintenance characteristic indicators are stored in the database. According to the data in the database, the functional relationship, structural rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com