Wig weft and production technology thereof

A technology for making wigs and wigs, applied in the field of wig hair curtains and their making processes, can solve the problems of uncomfortable wearing, unsightly wearing, frizzy wearing, etc., and achieve the effect of convenient wearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

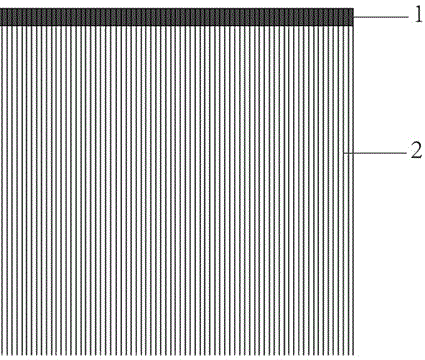

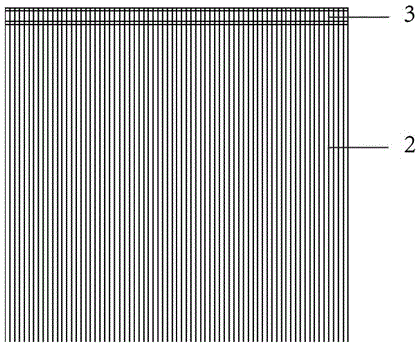

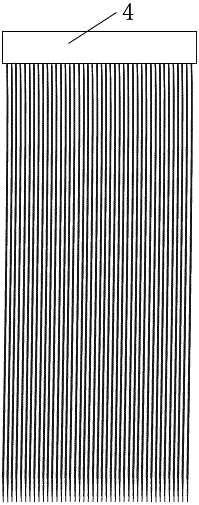

[0022] Embodiment 1 The wig hair curtain of the present invention has a structure such as figure 1 with figure 2 As shown, including the hair 2, one end of the hair is flat, and the flat end forms a base part 3 with a certain width through glue and a nylon ribbon 1. In order to facilitate wearing, a double-sided adhesive tape 4 is pasted on the nylon ribbon 1, such as image 3 shown; or sew a hair extension ring 5 or a clip 6 on the nylon ribbon 1, such as Figure 4 with Figure 5 shown.

Embodiment 2

[0023] Embodiment 2 The manufacturing method of the wig hair curtain of the present invention comprises the following steps:

[0024] (1) Prepare a part of hair that is very neat at one end and has a natural width at the other end.

[0025] (2) Choose the matching ribbon according to the hair color. The width of the ribbon can be flexibly adjusted according to the needs, generally 4mm is suitable. Different materials can be used for the material, and nylon ribbons are commonly used.

[0026] (3) Prepare glue; the mass percentage of glue is: resin A glue 20%, resin B glue 7.5%, resin C glue 25%, polyester 1070 25%, methyl ethyl ketone 22.5%; the above components are mixed and stirred Evenly.

[0027] (4) Put the adjusted glue into the plastic box of the double needle machine, install the ribbon on the machine, spread the neat end of the hair on the nylon ribbon, and make a hair curtain with uniform density.

[0028] (5) After the hair curtain is completed, bake it in a light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com