Grinding wheel and grinding method thereof for aero turbine guide vane edge plate grinding

A technology of guide vanes and aviation turbines, which is applied to bonded grinding wheels, grinding/polishing equipment, grinding machines, etc., can solve the problems of low linear speed, low grinding efficiency, and severe wear of grinding wheels, and achieves low processing efficiency. Optimizing the effect of the grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment is to provide a kind of aviation turbine guide vane edge plate grinding method, which has the following steps: Step 1, grinding preparation

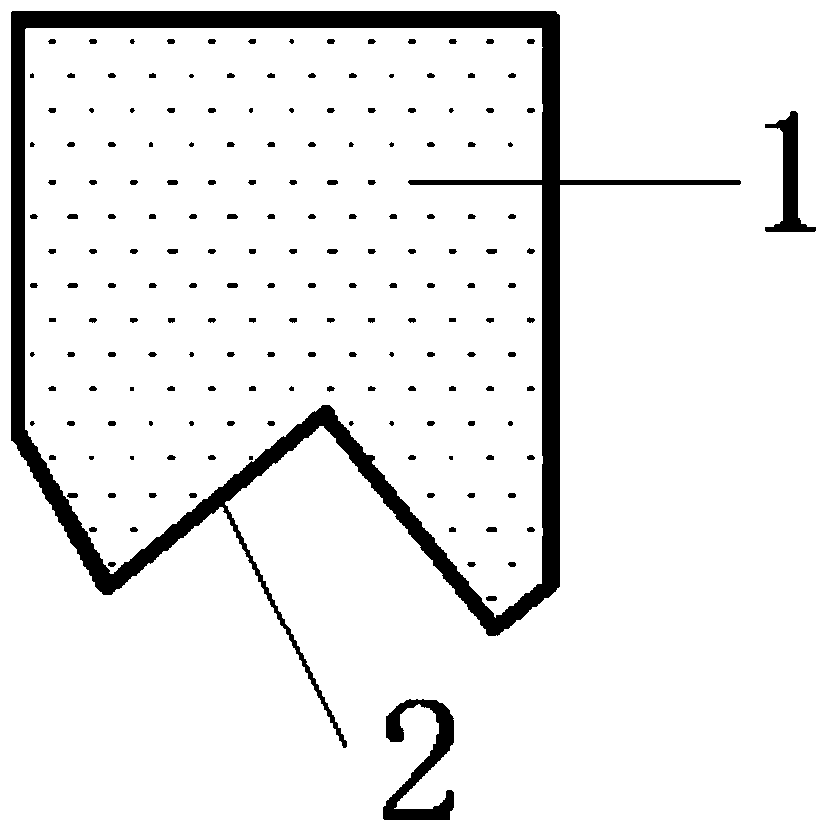

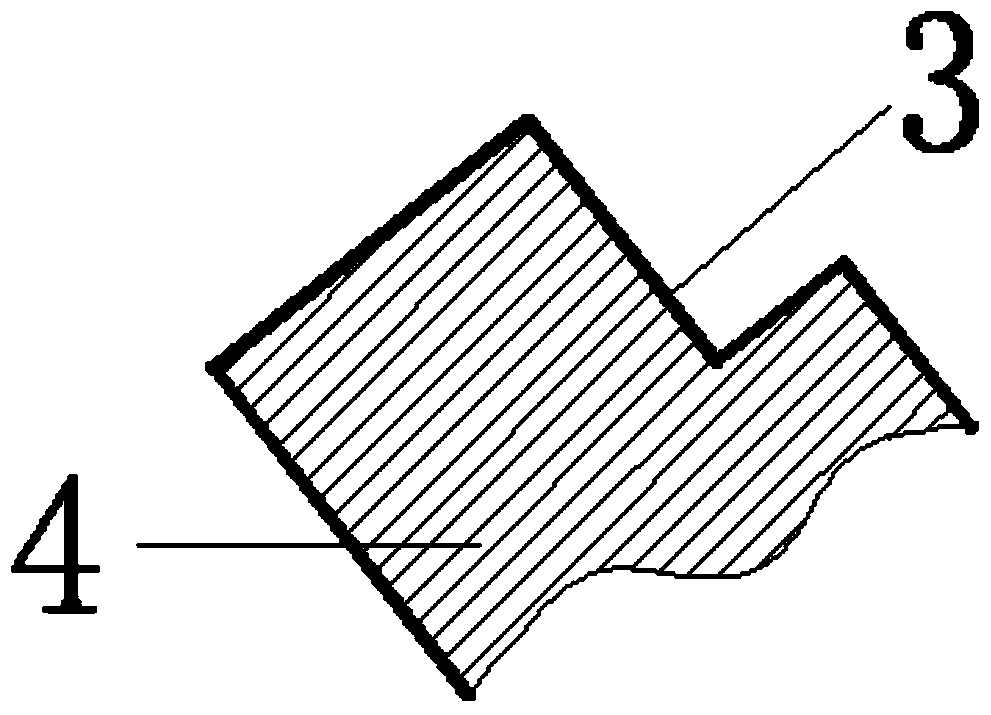

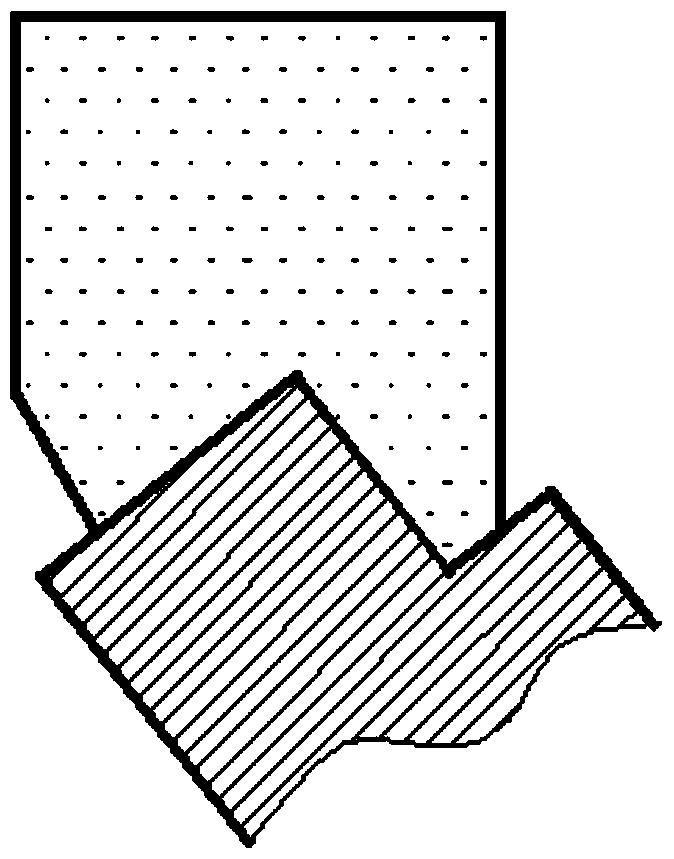

[0024] Fix the upper and lower edge plates of the guide vane; select the grinding wheel 1; correspond the annular right-angle groove 2 of the grinding wheel to the outer side 4 of the edge plate;

[0025] Step 2. Initial Grinding

[0026] First set the grinding parameters as follows: the linear speed of the grinding wheel is 30 m / s, the depth of cut is 0.4 mm, and the feed rate is 800 mm / min, and then the grinding is carried out;

[0027] Step 3. Adjust

[0028] Observe whether there are black spots at the grinding position on the outer side of the flange, and the level is 5 m / s. If there are black spots, reduce the linear speed of the grinding wheel by one level, and grind again when the depth of cut and feed speed remain unchanged; If there are no black spots, increase the linear speed of the grinding w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com