Forward, idle and reverse steering mechanism

A one-way ratchet and axial direction technology, which is applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of no working state, inconvenient switching, and inability to accurately locate specific positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

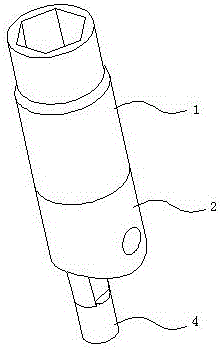

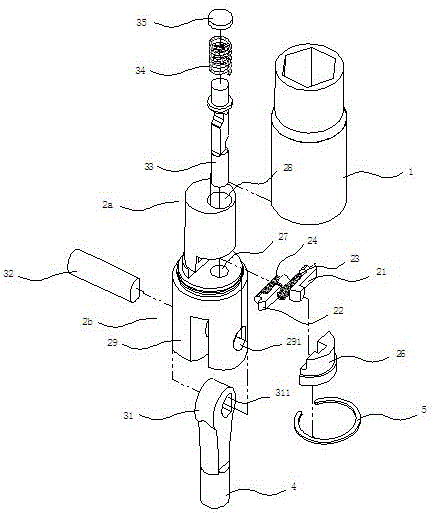

[0068] Figure 1-8 Shown is the structure of the forward and reverse reversing mechanism of the present invention, which includes: a double ratchet sleeve 1 , a ratchet seat 2 , an eccentric drive mechanism 3 , and a tool handle 4 .

[0069] A pair of ratchet sets 1, such as Figure 9 As shown, the double ratchet sleeve 1 is distributed with a first one-way ratchet ring gear 11 and a second one-way ratchet ring gear 12 in the axial direction, and the first one-way ratchet ring gear 11 and the second one-way ratchet ring gear 12 One of them is a positive one-way ratchet ring gear, and the other is a reverse one-way ratchet ring gear.

[0070] In this embodiment, the first one-way ratchet ring gear 11 and the second one-way ratchet ring gear 12 adopt a stepped structure, that is, the diameters of the first one-way ratchet ring gear 11 and the second one-way ratchet ring gear 12 are different. It is beneficial to directly integrally process and form the first one-way ratchet ri...

Embodiment approach

[0081] In the eccentric drive mechanism 3 , the combination of the pawl driving rod 33 and the elastic reset member is used to realize the actions of the first pawl 21 and the second pawl 22 . That is: the first ratchet 21 and the second ratchet 22 are driven by the ratchet drive rod 33 to move in a single direction perpendicular to the axis of the double ratchet sleeve, and the first ratchet 21 and the second ratchet are driven by the elastic reset member. The pawl 22 moves in the other unidirectional direction perpendicular to the axis of the double ratchet sleeve 1 .

[0082] The specific plan is as follows:

[0083] The length direction of the ratchet drive rod 33 is defined to be parallel to the axis of the double ratchet sleeve 1, and the two sides of the ratchet drive rod 33 in the length direction are defined as the first side and the second side;

[0084] Such as Figure 12 and 13 As shown, the ratchet driving rod 33 adopts a segmented wedge-shaped structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com