Forward idling and reverse steering mechanism

A one-way ratchet, axial direction technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of not having a working state, not being able to cut off the torque transmission at the same time, and being unable to perform accurate positioning at a specific position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

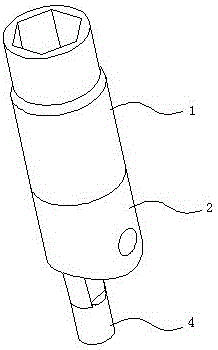

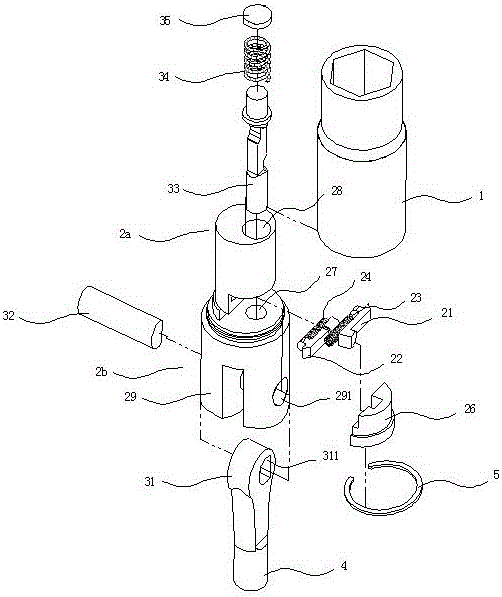

[0077] Figure 1-8 Shown is the structure of the forward-air-reverse steering mechanism of this embodiment, which includes: double ratchet sleeve 1 , ratchet seat 2 , eccentric drive mechanism 3 , and tool handle 4 .

[0078] A pair of ratchet sets 1, such as Figure 9 As shown, the double ratchet sleeve 1 is distributed with a first one-way ratchet ring gear 11 and a second one-way ratchet ring gear 12 in its axial direction, and the first one-way ratchet ring gear 11 and the second one-way ratchet ring gear One of the ring gears 12 is a positive one-way ratchet ring gear, and the other is a reverse one-way ratchet ring gear.

[0079] In this embodiment, the first one-way ratchet ring gear 11 and the second one-way ratchet ring gear 12 adopt a stepped structure, that is, the first one-way ratchet ring gear 11 and the second one-way ratchet ring gear 12 The diameters are different, which is conducive to the direct integral processing and molding of the first one-way ratchet ...

Embodiment 2

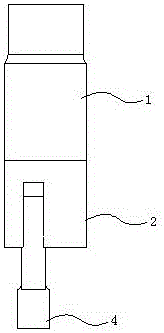

[0127] Figures 19-21 Shows the structure of the forward and reverse steering mechanism of this embodiment, including the double ratchet sleeve 1 , , pawl seat 2 , , Eccentric drive mechanism 3 , and tool handle 4 , , compared with Example 1, change the pawl seat 2 , The upper driving rod guide hole 27 extending from the upper area to the lower area , position, eccentric drive mechanism 3 , Middle eccentric wheel 31 , , eccentric axle 32 , And pawl driving rod 33 , Structure.

[0128] Such as Figure 20 As shown, the drive rod guide hole 27 of the drive rod guide hole in this embodiment , The axis is located in the center of the ratchet seat, and with the double ratchet sleeve 1 , The axes coincide; this design is convenient for processing and beautiful.

[0129] In this embodiment, in the structure using the split pawl seat, such as Figure 21 As shown, the first pawl 21 in this figure , , the second pawl 22 , The working surface is on the side of the movable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com