Three-roving controlled feeding spinning device and three-roving controlled feeding spinning method

A technology of three rovings and rovings, applied in spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problems of poor yarn evenness, inability to freely adjust the main draft, and low cost of transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

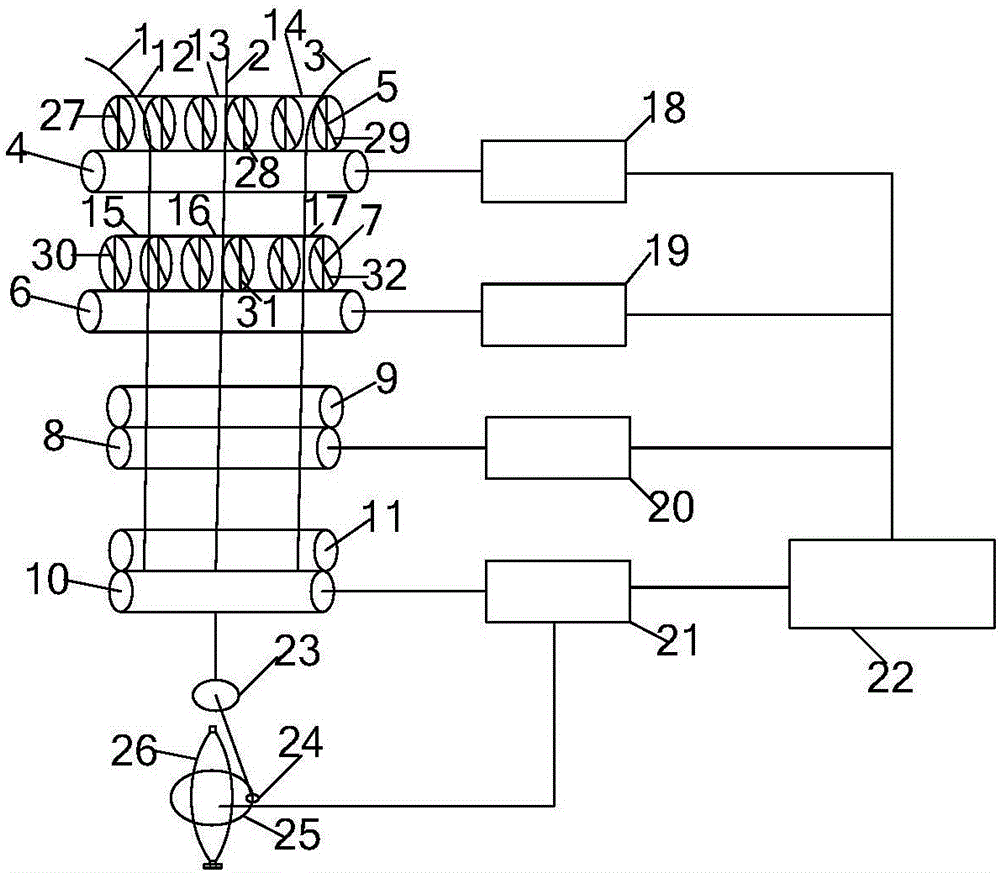

[0020] Depend on figure 1 As shown, a three-rove controllable feeding spinning device includes a rear roller drafting pair composed of a rear roller 4 and a rear rubber roller 5, a middle rear roller draft pair composed of a middle rear roller 6 and a middle rear rubber roller 7 , the middle front roller drafting pair composed of the middle front roller 8 and the middle front rubber roller 9, the front roller draft pair composed of the front roller 10 and the front rubber roller 11, the rear rubber roller includes the rear rubber roller shaft, and the rear rubber roller shaft The first left apron 12, the first middle apron 13, and the first right apron 14 are installed sequentially from left to right. The first left apron, the first middle apron, and the first right apron pass through the circle respectively The first left lifting pin 27, the first middle lifting pin 28, and the first right lifting pin 29 are connected with the rear rubber roller shaft by a bearing structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com