Rough yarn control feeding spinning device and method

A roving and single-spindle technology, which is applied in the field of roving controllable feeding spinning device, can solve the problems of poor yarn dryness uniformity, low transformation cost, main draft can not be adjusted freely, etc., to improve the comprehensive quality of yarn , the effect of increasing varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

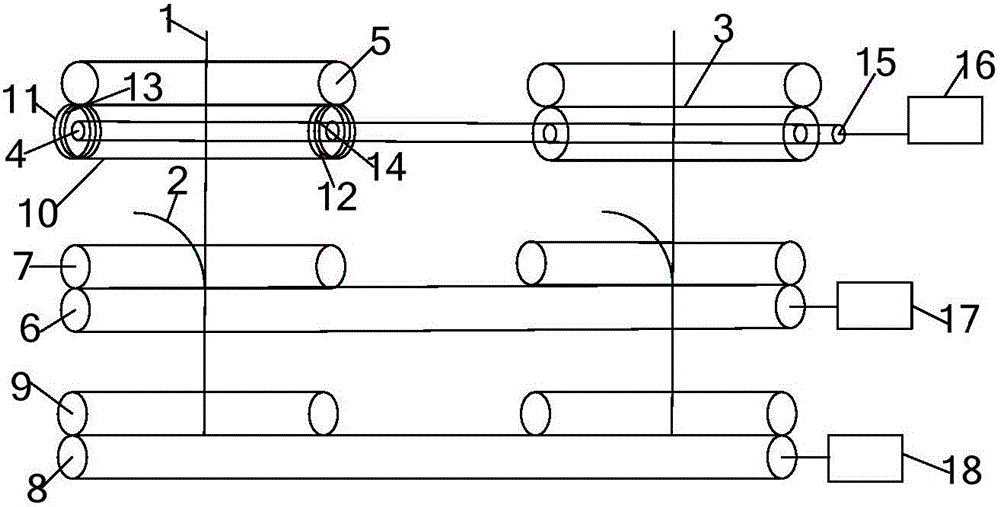

[0010] Depend on figure 1As shown, a roving controllable feeding spinning device is composed of a single-spindle spinning device, and the number of the single-spindle spinning device is between 200-510. The single-spindle spinning device includes a rear roller 4 and a rear cot The rear drafting roller pair consisting of 5, the middle drafting roller pair consisting of the middle roller 6 and the middle rubber roller 7, the front drafting roller pair consisting of the front roller 8 and the front rubber roller 9, the middle roller includes the middle roller shaft, The middle roller shaft is a solid cylinder, and the middle roller shafts of each single-spindle spinning device are fixedly connected to each other, and the middle roller sleeves are fixedly connected to the corresponding middle roller shafts of each single-spindle spinning device. The middle rubber rollers of the spinning device are independent of each other, and the front rollers include the front roller shaft, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com