Production process for aloe modified viscose acetal fiber/corn weft cutting motif fabric

A viscose fiber and production process technology, applied in the direction of fabric, fiber treatment, plant fiber, etc., can solve the problems of not being resistant to high temperature, and achieve the effects of eliminating reed marks, improving efficiency, and high shed definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

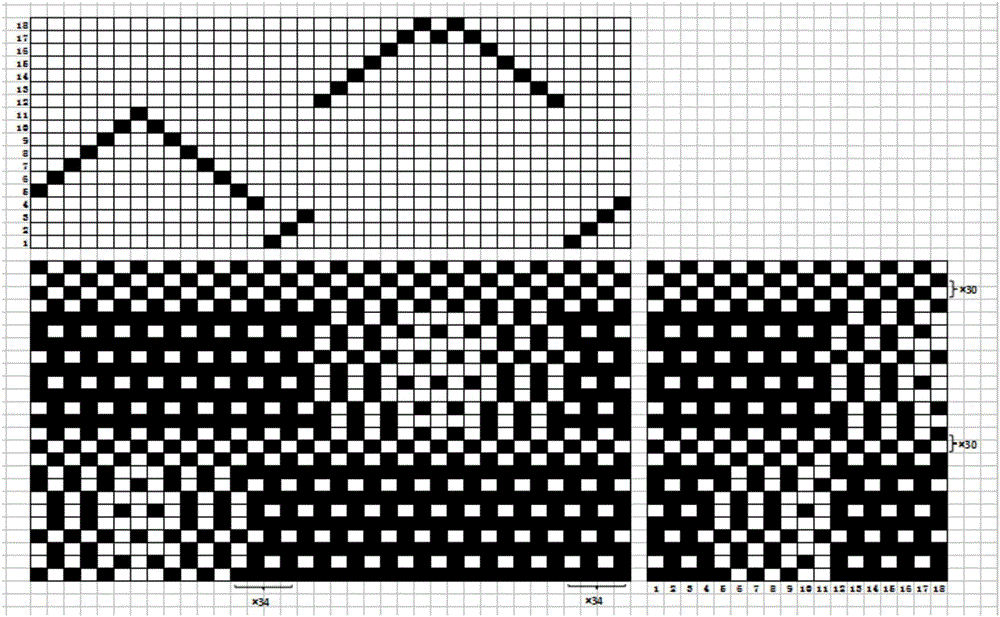

[0027] Such as figure 1 Shown, a kind of production technology of aloe modified viscose fiber / cotton latitude sheared flower fabric, comprises the steps:

[0028] (1) Winding process

[0029] Adopt NO.21C winding machine, the winding speed is 600m / min; the winding tension is 15g; the winding density is 0.45g / cm 3 ;Main yarn clearing process parameters: N (nep) is 350%; S (short thick place) is 220%×2.0cm; L (long thick place) is 40%×40cm; T (long detail) is -35% ×40cm;

[0030] (2) Warping process

[0031] Adopt GA126P new high-speed batch warping machine with warping speed of 600m / min; total number of warps is 9224; warping tension: front row 6g, middle row 5g, rear row 4g, side yarn 7g; warping shaft is 659 ×12+658×2 shafts; winding density is 0.50g / cm 3 ;

[0032] (3) Sizing process

[0033] Zook S432 type sizing machine is used, the size formula is as follows: TB-225 50kg; PVA205MB 25kg; 2-naphthol 3kg; , the slurry viscosity is 11s, the pH value of the slurry tank...

specific Embodiment 2

[0043] Such as figure 1 Shown, a kind of production technology of aloe modified viscose fiber / cotton latitude sheared flower fabric, comprises the steps:

[0044] (1) Winding process

[0045] Adopt NO.21C winding machine, the winding speed is 1000m / min; the winding tension is 15g; the winding density is 0.55g / cm 3 ;Main yarn clearing process parameters: N (nep) is 350%; S (short thick place) is 220%×2.0cm; L (long thick place) is 40%×40cm; T (long detail) is -35% ×40cm;

[0046] (2) Warping process

[0047] Adopt GA126P new high-speed batch warping machine, warping speed 900m / min; total warp number 9224; warping tension: front row 6g, middle row 5g, rear row 4g, side yarn 7g; warping shaft is 659 ×12+658×2 shafts; winding density is 0.60g / cm 3 ;

[0048] (3) Sizing process

[0049] Zoke S432 type sizing machine is used, the size formula is as follows: TB-225 50kg; PVA205MB 25kg; 2-naphthol 3kg; , the slurry viscosity is 11s, the pH value of the slurry tank is 7, the pr...

specific Embodiment 3

[0059] Such as figure 1 Shown, a kind of production technology of aloe modified viscose fiber / cotton latitude sheared flower fabric, comprises the steps:

[0060] (1) Winding process

[0061] Adopt NO.21C winding machine, the winding speed is 800m / min; the winding tension is 15g; the winding density is 0.48g / cm 3 ;Main yarn clearing process parameters: N (nep) is 350%; S (short thick place) is 220%×2.0cm; L (long thick place) is 40%×40cm; T (long detail) is -35% ×40cm;

[0062] (2) Warping process

[0063] Adopt GA126P new high-speed batch warping machine with warping speed of 700m / min; total number of warps is 9224; warping tension: front row 6g, middle row 5g, rear row 4g, side yarn 7g; warping shaft is 659 ×12+658×2 shafts; winding density is 0.56g / cm 3 ;

[0064] (3) Sizing process

[0065] Adopt Zuke S432 type sizing machine, the size formula is as follows: TB-225 50kg; PVA205MB 25kg; 2-naphthol 3kg; , the slurry viscosity is 11s, the pH value of the slurry tank i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding density | aaaaa | aaaaa |

| Winding density | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com