Anti-seismic reinforced concrete structure column

A technology of reinforced concrete and structural columns, which is applied in basic structural engineering, construction, etc., can solve the problem of high construction cost, achieve the effect of not easy to break, improve seismic effect, and good seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

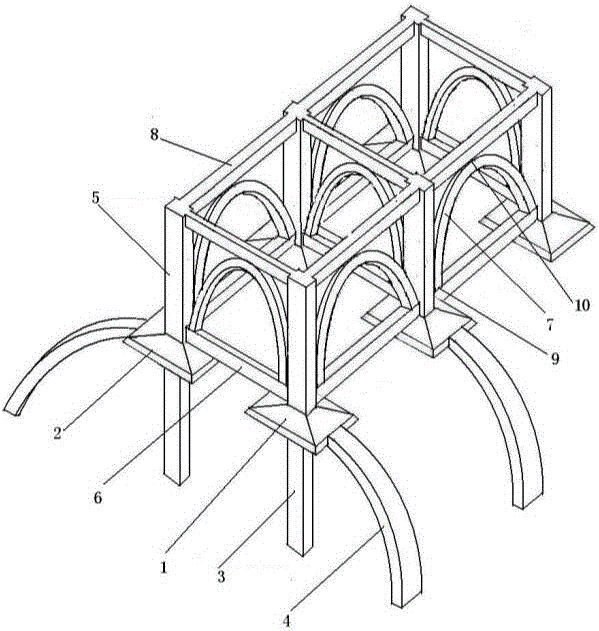

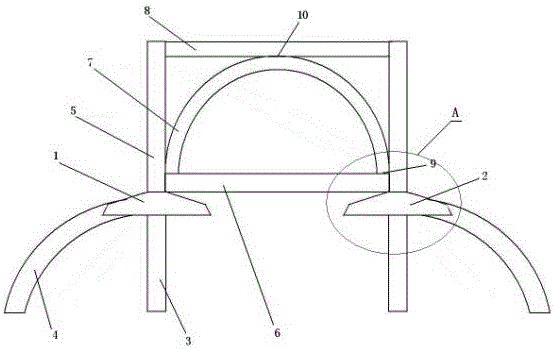

[0016] As shown in the figure, an earthquake-resistant reinforced concrete structural column is prepared, including a foundation 1, which is an independent foundation 2; a vertical pipe pile 3 and an arc pipe pile 4 are arranged under the foundation 1; a foundation is arranged on the surface of the foundation 1 Column 5, foundation beam 6, arch column beam 7 and cross beam 8; the vertical pipe pile 3 is connected to the foundation 1 and directly installed under the foundation 1; the arc pipe pile 4 is connected to the foundation 1 and the outside of the foundation 1 is The starting point is installed in an arc shape outwards and downwards; the foundation column 5 is connected to the foundation 1 and is directly installed vertically on the surface of the foundation 1; the bottom end of the foundation beam 6 connected to the foundation column 5 is installed horizontally and connected to another The bottom ends of a foundation column 5 are connected; the top of the beam 8 connecte...

Embodiment 2

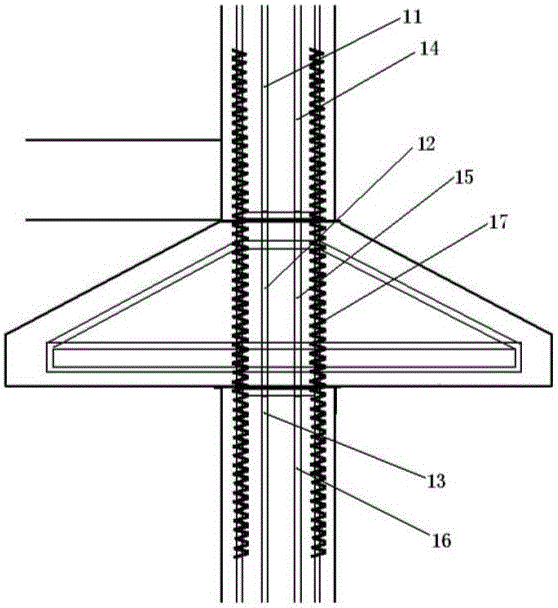

[0019] As shown in the figure, a shock-absorbing device is added on the basis of Embodiment 1. The shock-absorbing device is installed at the node of the foundation 1 outside the building. The shock-absorbing device includes the lower half of the reinforcement cage of the foundation column. 11. The entire foundation reinforcement cage 12 and the upper half of the vertical pipe pile reinforcement cage 13, of which the main reinforcement of the lower half of the foundation column reinforcement cage 14, the main reinforcement of the whole foundation reinforcement cage 15 and the main reinforcement of the upper half of the vertical pipe pile reinforcement cage 16 direct fixed-phase connection or the whole main reinforcement; when installing the main reinforcement on the inner and outer sides of these connected foundation structures, the reinforcement spring 17 is set on the main reinforcement, and then the concrete is poured to make the reinforcement spring and the main reinforcemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com